Custom FR-4 CNC Machining Case Study: How We Delivered 6000 High-Precision Insulation Parts in 3 Days

Custom FR-4 CNC Machining Case Study: How We Delivered 6000 High-Precision Insulation Parts in 3 Days

Precision, Performance, and Partnership — What Makes Custom FR-4 Projects Succeed?

When you're sourcing custom FR-4 components for demanding electrical applications, it's never just about materials — it's about the team that transforms a sheet into a functional, precision-cut, flame-retardant solution. This case study reveals how BeePlastic worked side-by-side with an electrical equipment manufacturer to deliver 6000 CNC-machined FR-4 insulation parts in just three days — from CAD drawing to shipment. For engineers and procurement teams in the USA, Europe, and Australia, this is a story of responsiveness, reliability, and results.

Understanding the Real Requirement: More Than Just a FR-4 Sheet

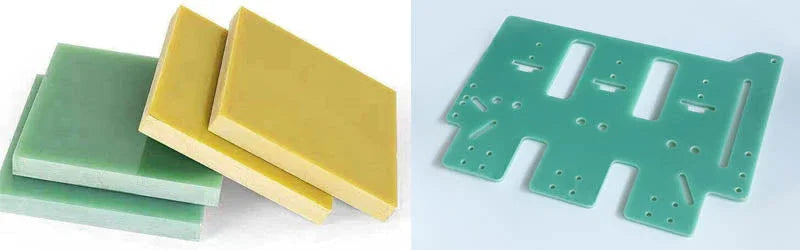

The client — a well-established electrical equipment manufacturer — approached us with a critical project: they needed thousands of glass epoxy FR-4 components for an upcoming system launch. But this wasn’t a standard sheet-cutting task.

They needed:

-

Tight dimensional tolerances

-

Flame-retardant compliance (UL94 V-0)

-

Perfectly smooth edges

-

Precision hole placement

-

And complete adherence to their CAD drawings and 3D files

In other words, this project demanded not just raw material — but a fully integrated custom machining solution based on deep material knowledge and excellent CNC execution.

🟩 Need High-Quality FR-4 Sheets for Your Own Machining Project?We offer industrial-grade FR-4 fiberglass epoxy sheets in multiple sizes and thicknesses—perfect for prototyping, insulation, and structural use. 🛒 ✔ CNC-Friendly | 📏 Various Thicknesses | 🚚 Global Shipping Available 👇 Click the image below to explore our FR-4 collection now. 🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 FR4 fiberglass plastic |

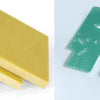

FR-4 vs. G10: How We Helped the Customer Make the Right Call

At the initial consultation stage, the client was undecided between G10 and FR-4 epoxy laminate boards. We helped them analyze the technical differences:

-

Both G10 and FR-4 are fiberglass-reinforced epoxy composites, with excellent electrical insulation and mechanical strength.

-

However, only FR-4 contains flame-retardant additives, making it compliant with UL94 V-0 standards, ideal for electrical safety-critical components.

Through transparent consultation and our internal material comparison documentation, we guided them toward FR-4 — the safe and industry-standard choice for electrical insulation parts.

From Drawings to Prototypes: A Collaborative Engineering Process

Once the material was confirmed, our team — composed of sales, engineering, and production leads — kicked off a coordinated process:

-

Carefully reviewed the client’s CAD drawings and 3D models

-

Determined the best tool paths for CNC routing and hole drilling

-

Simulated edge contouring processes to ensure zero burrs and no delamination

-

Selected specialized cutters suitable for glass-reinforced epoxy laminates

We didn’t treat this as a one-way fabrication task. Instead, we initiated a multi-round communication loop with the client, adjusting machining tolerances and optimizing the layout for yield and consistency.

A sample batch was produced within days, allowing the customer to validate real-world fit and finish. Their feedback? “Exactly what we needed — ready for full production.”

Delivering 6000 CNC-Machined FR-4 Parts in Just 3 Days

After green-lighting the prototypes, our challenge became one of speed without compromise.

-

We rapidly scaled the machining program using multi-spindle CNC equipment for parallel production.

-

Implemented real-time quality control checkpoints at every stage — especially for hole precision and edge quality.

-

Our logistics team negotiated bulk freight discounts, ensuring the client saved on international shipping even on a tight schedule.

The full 6000-part order was produced, packed, and dispatched within 3 working days — a timeline we proudly met without a single deviation in quality.

Feedback That Fuels Us: What the Client Said

Once the shipment arrived, we received a message from the client that made all the effort worthwhile:

“Your team not only hit every technical spec — you worked with us late on Sundays, stayed flexible during last-minute adjustments, and made sure everything shipped on time. We’re recommending BeePlastic to our other departments as a trusted machining partner.”

This kind of endorsement validates our core values: technical precision + human collaboration = long-term trust.

Why Engineers and Procurement Teams Choose BeePlastic for FR-4 Machining

Whether you're in Australia, the United States, or Germany, if you're sourcing custom CNC FR-4 components, here’s why BeePlastic is a reliable partner:

-

✅ Expertise in epoxy glass laminates: FR-4, G10, 3240, and more

-

✅ Integrated services: material selection, CNC machining, laser marking, and quality control

-

✅ Flexible order sizes: from prototypes to thousands of parts

-

✅ Responsive support: fast communication, multi-language service, and Sunday replies (yes, really)

Let’s Build Your Custom FR-4 Solution

Have a drawing? A sketch? A requirement for flame-retardant epoxy laminate machining?

We’d love to help.

🔹 Upload your CAD or 3D file

🔹 Tell us your timeline and quantity

🔹 Get a fast, professional quote from our team

👉 Contact Us for Custom FR-4 Machining Solutions

🛠 Want Us to Machine Your Custom FR-4 Parts?Just like we delivered 6000 precision components in 3 days, we can bring your design to life—from drawing to part, fast. 📩 Upload your drawing or describe your specs. We’ll quote you within 24 hours. 👇 Click the image below to start your FR-4 project today. 🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 FR4 fiberglass plastic

|

-

Posted in

CNC drilling FR-4, custom CNC machining, custom FR-4 machining, custom insulation parts, electrical insulation components, epoxy glass laminate, epoxy laminate machining, flame-retardant materials, FR-4 CNC machining, FR-4 CNC parts, FR-4 sheet cutting, FR-4 sheet processing, FR-4 supplier, G10 vs FR-4, high-precision CNC, high-precision FR-4, insulation component supplier, UL94 V-0