Polycarbonate Machine Guards in 10 Days: CNC-Cut, UV-Resistant

1. The Email That Spelled “Enough”

Subject: “Repeated Guard Failures — Need a Real Fix”

Mark’s email arrived mid-morning. It wasn’t the first time we’d heard from a maintenance manager dealing with cracked guards, but this one had urgency written all over it.

Attached were high-resolution photos: a clear acrylic machine guard with a fracture radiating from a bolt hole, the edges clouded, and notes scrawled alongside a measuring tape. In the body, he detailed the history:

-

Three replacements in two months on the same production line.

-

Downtime averaging 90 minutes per incident.

-

Operators frustrated by poor visibility during inspection.

-

Mounting holes that no longer matched perfectly due to years of inconsistent replacements.

Mark’s closing line was blunt:

“We can’t keep doing this. If you can give me a polycarbonate machine guard that fits, stays clear, and doesn’t crack, I’m ready to move now.”

2. Seeing the Problem Through the Customer’s Eyes

From our experience, replacing acrylic with more acrylic wasn’t going to solve anything. But before suggesting materials, we needed to understand his exact environment.

Our reply didn’t include a price — it included questions:

-

What cleaning chemicals are used, and how often?

-

What’s the lighting like over the line? Any UV exposure?

-

Which measurements are critical, and which can be adjusted?

-

How much time can the team allow for a changeover?

-

Is operator visibility just for convenience, or a safety requirement?

Mark’s responses painted a clear picture:

Daily caustic washdowns. Bright, UV-heavy LED lighting. Mounting holes that had drifted slightly over the years. A strict target of five minutes max per guard during changeovers. And yes — clear visibility was mandated by their safety protocols.

💡 Need Material Now?For tough, clear machine guards, choose polycarbonate sheets—cut to your size, UV-resistant, impact-safe. ✅ Cut-to-size & fast dispatch 🚚 |

3. Why UV-Resistant Polycarbonate Was the Right Choice

We explained to Mark why UV-resistant polycarbonate machine guards were the logical solution:

-

Impact resistance: Multiple times stronger than acrylic, able to handle repeated fastening without cracking.

-

UV stability: Maintains clarity under constant bright lighting and harsh cleaning.

-

CNC cut to size: Matches existing mounts exactly, avoiding costly frame modifications.

-

From-stock availability: Our cut-to-size polycarbonate sheet inventory meant no lead time waiting for material.

We sent him our material spec link so he could see exactly what we were proposing:

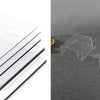

Clear Polycarbonate Sheets – Cut to Size & Impact-Resistant

And for the complete, ready-to-install option:

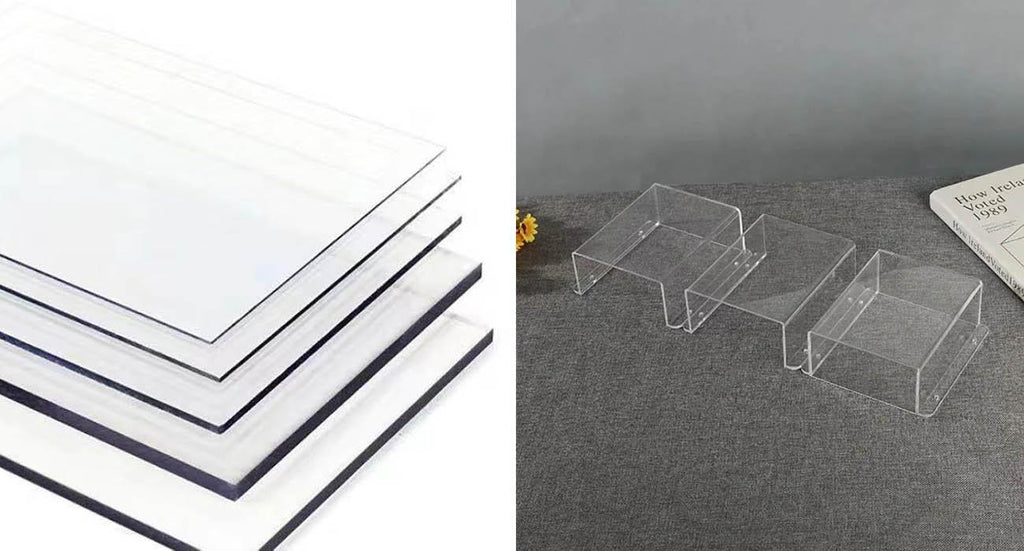

Precision CNC Plastic Machining Services

4. From Measurements to a Mount-Matched CAD

Mark’s email included precise measurements, but we’ve learned that real-world parts don’t always match drawings. We asked him to ship one of the old guards to us for verification.

Our inspection revealed two mounting holes were off by 1.5 mm from the drawing. In a rigid install, that’s the difference between a guard that slides into place and one that needs to be forced — which can start micro-cracks.

We rebuilt the CAD around the actual hole positions. The guard edges were adjusted for smooth clearance, and corner radii were added to reduce stress concentrations.

This is part of our Mount-Match First approach — designing to fit the reality of your equipment, not just the paper spec.

5. The BeePlastic 10-Day Timeline

Day 1–2 — Problem review, environment assessment, CAD corrections based on the physical sample.

Day 3 — Material selection from in-stock UV-resistant clear PC sheets — 8 mm for larger guards, 6 mm for smaller panels.

Day 4–5 — CNC programming with optimized nesting for minimal waste and lower reorder cost.

Day 6 — Machined two trial guards, performed edge trimming and deburring for safe handling, shipped them overnight to Mark.

Day 7 — Trial installation. Mark emailed back:

“Perfect fit. Holes line up without effort. Proceed with full run.”

Day 8–9 — Full production run. Every guard passed our go/no-go template for hole accuracy.

Day 10 — Shipment arrived labeled by station, with corner protectors and mounting notes.

6. Installation Day — A Different Experience

When the guards arrived, Mark’s team didn’t have to hunt for where each piece went — every panel was labeled with its exact location. The installation took under an hour for the full set.

Operators noticed the difference instantly:

-

Crystal-clear visibility during product checks.

-

No glare under the UV-heavy lights.

-

Safe, smooth edges that made handling comfortable.

Mark’s maintenance log now showed zero guard-related stoppages. For him, it wasn’t just about the material — it was about knowing the guards were designed for his line, by a team that understood the environment.

7. Three Weeks Later — The Follow-Up

Three weeks after installation, we received another email from Mark:

Subject: “No Failures”

“It’s been three weeks with no cracks, no haze, and changeovers under five minutes. The team is happy, and I’m not getting late-night failure reports. Keep the CAD and order notes — we’ll be upgrading the second line next quarter.”

8. Why Teams Choose BeePlastic for Polycarbonate Machine Guards

1) We start with your reality, not a catalog size

Our Mount-Match First process means we measure, verify, and design for your actual mounting points — so installation is fast and stress-free.

2) In-stock UV-resistant PC sheets

No waiting weeks for material. We stock a full range of cut-to-size polycarbonate sheets so urgent projects start immediately.

3) CNC precision for repeatable quality

Your first guard, your tenth guard, or your hundredth — all cut from the same CNC program, with the same fit.

4) Edge finishing for safety and longevity

We trim and deburr every edge to remove handling hazards and reduce stress points.

5) Reorder-ready documentation

Every project gets labeled parts, mounting notes, and stored CAD files for fast repeat orders.

9. Ready to End Your Guard Failures?

Option 1 — Material Now

Order from our Clear Polycarbonate Sheets – Cut to Size & Impact-Resistant. Choose your thickness, and we’ll cut to size for quick delivery.

Option 2 — Complete Solution

Upload your CAD to Precision CNC Plastic Machining Services. We’ll review, recommend the right material and thickness, and send a custom quote within 24 hours.

10. Final Word

Mark’s line hasn’t had a guard-related stoppage since. The operators work with better visibility, the changeovers are faster, and maintenance no longer worries about cracks under pressure.

When downtime costs add up, the right material and the right process aren’t an expense — they’re an investment.

🛠 We Build the Guard. You Run the Line.Send your drawing, we CNC cut, drill, bend, and finish polycarbonate guards—as fast as 10 days. ✔ MOQ 1 piece | sample friendly |

BeePlastic delivers both.

-

Posted in

case study, clear polycarbonate sheet, cnc plastic machining, CNC plastic machining services, CNC-Cut, CNC-cut polycarbonate, custom plastic machining, Cut to Size, cut to size polycarbonate sheet, Industrial Safety, Inspection Window, Machine Guard, Packaging Line, Polycarbonate, polycarbonate guard case study, polycarbonate machine guard, UV-Resistant, UV-resistant polycarbonate