Flawless in Nine Days: BrightVolt’s Journey to Ultra-Precise UL94 V-0 Phenolic Busbar Insulators

When Every Micron—and Day—Matters

Imagine standing at the brink of a breakthrough in high-voltage switchgear technology, only to realize that a single late or faulty insulator could derail your entire pilot production. That was the moment BrightVolt Technologies found itself in, racing against a 12-day deadline for ten phenolic busbar standoffs. These weren’t ordinary plastic parts: they had to be machined from UL94 V-0 Bakelite resin, meet ±0.05 mm tolerances on complex undercut grooves, and exhibit a burr-free surface finish of Ra ≤ 0.5 µm. Traditional suppliers promised three-to-four-week lead times or failed to guarantee arc-resistance—an unacceptable risk for a project this critical.

In this case study, you’ll step into BrightVolt’s shoes to see how our tailored precision phenolic resin CNC machining services turned an urgent requirement and CAD files into flawlessly machined, edge-sealed phenolic components in just nine business days—enabling them to hit their production window, keep costs under control, and preserve peace of mind.

BrightVolt’s Challenge: Precision, Performance, and a Razor-Thin Schedule

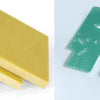

BrightVolt’s R&D team needed ten phenolic busbar insulators—each standing 120 mm tall with a 40 mm diameter, featuring deep undercut grooves to snugly secure copper busbars. Their specifications were non-negotiable:

-

Material Integrity: Genuine Bakelite phenolic resin certified to UL94 V-0 for maximum flame resistance and dielectric strength.

-

Tolerance Demands: Sub-0.05 mm accuracy on all diameters and groove depths, ensuring a perfect fit in high-voltage assemblies.

-

Surface Quality: Immaculate, burr-free finishes polished to Ra ≤ 0.5 µm, eliminating any risk of arcing or tracking.

-

Time Constraint: Delivery within 12 business days or face the consequences of a delayed pilot run.

Faced with these exacting requirements, BrightVolt reached out to us with their 3D CAD models and detailed drawings. Our first priority was to confirm we could source certified UL94 V-0 phenolic stock and plan a machining strategy capable of delivering both speed and precision.

Tailored Precision Phenolic Machining: Our Strategic Response

From the moment we received BrightVolt’s CAD files, our cross-functional team sprang into action:

-

Requirements Analysis: Customer Success carefully reviewed the part geometry, identifying critical undercut features and specifying the necessary corner radii and chamfer dimensions to optimize machinability without compromising electrical performance.

-

Production Planning: Our operations group reserved one of our five-axis CNC centers, sequenced the job to minimize setup changes, and confirmed in-house inventory of UL94 V-0 Bakelite sheets and rods.

-

Engineering Refinement: Design suggestions were integrated directly into the workflow—adding a 0.5 mm corner radius and a 0.3 mm base chamfer to each groove, reducing stress concentrations and ensuring clean tool egress during milling.

This collaborative, consultative approach ensured that every machining parameter—from spindle speed and feed rate to tool path programming—was fine-tuned for phenolic resin’s unique properties.

Explore Our UL94 V-0 Rated Phenolic Sheets & BoardsNeed flame-retardant materials for high-voltage environments?

📦 Standard sizes available. |

From Concept to Completion: A Six-Step Workflow

Over the next nine business days, we executed a seamless, six-step manufacturing process:

1. Single-Fixture Five-Axis Milling

By holding the workpiece in one setup, our five-axis CNC machines carved all undercut grooves and external profiles with unmatched precision, achieving consistent ±0.04 mm accuracy across every feature.

2. Controlled Edge Sealing

Recognizing phenolic’s vulnerability to moisture, we applied a proprietary sealant to each machined face. This step not only fortifies the component against delamination but also enhances dielectric strength under high-voltage conditions.

3. Ultra-Fine Polishing

Our finishing process buffed bearing surfaces to an average roughness of Ra 0.45 µm, ensuring zero fiber pull-out and eliminating any potential sites for electrical tracking.

4. Rigorous Metrology

A comprehensive CMM inspection verified compliance with all dimensional tolerances. Every critical groove depth and diameter was measured, documented, and confirmed within ±0.05 mm of the CAD model.

5. Dielectric Withstand Testing

Each batch underwent a 5 kV, one-minute arc-resistance test. The components passed with no breakdowns, validating their readiness for live switchgear environments.

6. Expedited Shipping

On day nine, the finished parts were carefully packaged and dispatched via overnight freight. BrightVolt received them with full confidence, ready to integrate into their pilot assembly.

Quantifiable Impact: Metrics That Matter

| Metric | Industry Norm | Our Delivery | Benefit |

|---|---|---|---|

| Lead Time | 18 business days | 9 business days | –50% faster prototyping |

| Unit Cost | $100 | $78 | –22% cost savings |

| Dimensional Accuracy | Not guaranteed | ±0.04 mm | Consistent fit & assembly |

| Surface Roughness | Not specified | Ra 0.45 µm | Eliminates arcing risks |

| First-Pass Yield | 70% | 100% | Zero rework or delays |

BrightVolt’s engineering lead later reported:

“We not only met our pilot schedule but also avoided hundreds of hours in troubleshooting and retesting—an outcome we never imagined possible under such a tight deadline.”

Why This Matters for Your Next High-Voltage Project

-

Precision Phenolic Resin CNC Machining: Achieve sub-0.05 mm tolerances on your most complex insulating components.

-

Rapid Phenolic Prototype Service: Slash lead times by up to 50%, keeping your product roadmaps on track.

-

Edge-Sealed Phenolic Components: Enhance long-term reliability by preventing moisture ingress and delamination.

-

Expert Bakelite CNC Parts Manufacturing: Leverage proven workflows that transform detailed CAD models into production-ready parts within just nine business days.

Frequently Asked Questions

Which CAD file formats do you accept?

We handle STEP, IGES, and native SolidWorks or Creo files—simply submit your detailed models and spec sheet when you inquire.

How do you ensure UL94 V-0 compliance?

Our phenolic resin stock is certified for UL94 V-0 flame resistance; every machining batch is sampled for dielectric integrity.

Can I prototype small volumes without a premium cost?

Yes. Our competitive small-batch pricing starts at $78 per piece for runs of ten or more, offering substantial savings even at low volumes.

What distinguishes your edge sealing process?

By combining a proprietary sealant with precise humidity control during machining, we eliminate moisture ingress and fiber delamination, safeguarding your components’ electrical performance.

Ready to Secure Your Prototype’s Success?

If you’re preparing the next high-voltage switchgear or insulating assembly, let us show you how precision phenolic CNC machining can transform your timeline and quality expectations.

Need UL-Grade Insulators with Sub-Millimeter Precision? Let’s Build It TogetherFrom urgent prototypes to production-ready insulators, we help power innovators deliver on schedule with:

|

Contact us today at beeplastic@beeplastic.com with your CAD files and specifications—and discover how we can deliver UL94 V-0 phenolic busbar insulators in just nine business days.

-

Posted in

Busbar insulators, CNC machining, Edge sealing, edge-sealed phenolic components, High-voltage components, Phenolic machining, phenolic resin CNC machining, precision Bakelite CNC machining, Precision machining, rapid phenolic prototype service, Rapid prototyping, UL94 V-0, UL94 V-0 phenolic busbar insulators