Sustainable Construction Materials: Why UHMW-PE is a Top Choice for Infrastructure Projects

Synopsis

In today's rapidly evolving construction industry, sustainable construction materials are more critical than ever. My latest blog post, "Sustainable Construction Materials: Why UHMW-PE is a Top Choice for Infrastructure Projects," delves into the myriad benefits and applications of Ultra-High Molecular Weight Polyethylene (UHMW-PE). Discover how UHMW-PE's unique properties, such as exceptional strength, durability, and environmental benefits, make it an ideal material for modern infrastructure.

The post begins with an introduction to UHMW-PE, explaining its composition and importance in sustainable construction. We then explore the material properties that set UHMW-PE apart, including its high abrasion resistance and impact strength, which contribute to long-lasting and sustainable infrastructure.

Environmental considerations are at the forefront, with a detailed look at the eco-friendly aspects of UHMW-PE, including its recyclability and lower carbon footprint compared to traditional materials like steel and concrete. Specific applications in building infrastructure are highlighted, showcasing the versatility of UHMW-PE sheets in various construction projects.

Real-world case studies illustrate successful implementations of UHMW-PE, providing concrete examples of its benefits. A comparison with traditional construction materials further emphasizes UHMW-PE's superior performance and sustainability.

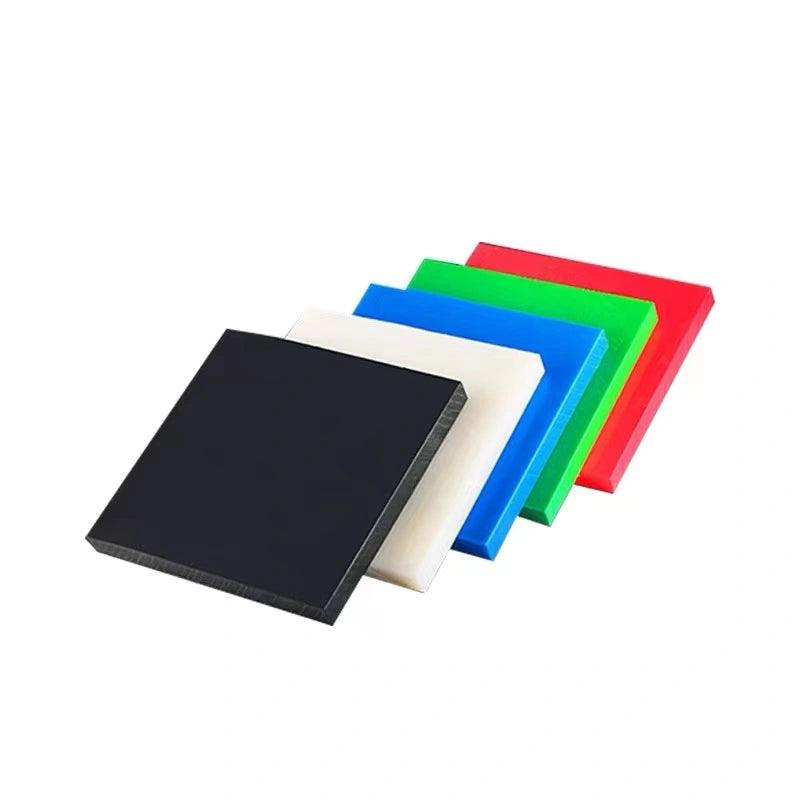

The post also explores innovative uses of color UHMW-PE in modern architecture, demonstrating its aesthetic and functional advantages. Finally, we look at future trends and the pivotal role UHMW-PE will play in advancing green building initiatives.

Join me in exploring how UHMW-PE is revolutionizing the construction industry, paving the way for a more sustainable future.

Introduction to UHMW-PE and Its Importance in Sustainable Construction

What is UHMW-PE?

Ultra-High Molecular Weight Polyethylene (UHMW-PE) is a type of thermoplastic polyethylene known for its extremely long molecular chains, which impart exceptional properties. These long chains result in a very tough material with high impact strength and excellent abrasion resistance. UHMW-PE is processed into sheets, rods, and other forms through methods like compression molding and ram extrusion, making it a versatile material for various industrial applications.

Why UHMW-PE is Gaining Popularity in the Construction Industry

The construction industry is increasingly focusing on sustainability and the durability of materials. UHMW-PE stands out due to its remarkable resistance to wear, chemicals, and impact, translating into longer-lasting infrastructure with reduced maintenance costs. As builders and architects seek materials that can withstand harsh conditions while supporting sustainable practices, UHMW-PE is becoming a preferred choice.

Key Properties of UHMW-PE

UHMW-PE offers several properties that make it ideal for sustainable construction:

- High Abrasion Resistance: This property makes UHMW-PE highly durable, suitable for environments where materials are subject to constant wear and tear.

- Impact Strength: UHMW-PE can absorb high impacts without cracking or breaking, ensuring the integrity of structures even under extreme conditions.

- Chemical Resistance: Its resistance to various chemicals, including acids and bases, means it can be used in diverse environments without degrading.

- Low Friction Coefficient: This makes UHMW-PE an excellent choice for applications where smooth movement is crucial, such as in conveyor systems and sliding components.

Environmental Benefits of UHMW-PE

Sustainability is a key consideration in modern construction projects. UHMW-PE contributes positively in several ways:

- Recyclability: UHMW-PE is recyclable, reducing waste and supporting circular economy practices.

- Lower Carbon Footprint: Compared to traditional materials like steel and concrete, UHMW-PE has a significantly lower carbon footprint during production and use.

- Longevity: The durability and low maintenance requirements of UHMW-PE result in fewer replacements and repairs, leading to less resource consumption over time.

Applications of UHMW-PE in Sustainable Construction

UHMW-PE sheets are used in a variety of construction applications, from foundation linings to protective barriers. Their lightweight nature and ease of fabrication make them suitable for custom components in construction projects. Specific uses include:

- Foundation Linings: Protecting against moisture and chemical ingress.

- Sliding Surfaces: Reducing friction in moving parts, enhancing efficiency and lifespan.

- Protective Barriers: Offering impact resistance in areas prone to mechanical stress.

Case Studies Highlighting UHMW-PE Successes

Numerous projects worldwide have successfully integrated UHMW-PE into their construction processes. These case studies highlight the material's ability to improve performance and sustainability:

- Bridges and Docks: Use of UHMW-PE in dock fenders and bridge supports to withstand constant water exposure and mechanical impacts.

- Industrial Floors: Implementation in warehouses and factories where heavy equipment movement requires durable flooring solutions.

Future Trends in Sustainable Construction with UHMW-PE

As the push for green building continues, UHMW-PE is expected to play a pivotal role in advancing sustainable construction practices. Innovations in color UHMW-PE offer aesthetic and functional benefits, expanding its use in modern architecture. The trend towards eco-friendly and cost-effective materials will likely see increased adoption of UHMW-PE across various construction sectors.

By integrating UHMW-PE into construction projects, builders and architects can contribute to a more sustainable future, ensuring durability, efficiency, and environmental responsibility in their designs.

UHMW-PE Material Properties: Strength, Durability, and Sustainability

High Strength and Impact Resistance

Ultra-High Molecular Weight Polyethylene (UHMW-PE) is renowned for its exceptional strength. This material's molecular structure, characterized by extremely long polymer chains, contributes to its high impact resistance. UHMW-PE can absorb significant energy without cracking or breaking, making it ideal for applications where materials are subjected to heavy impacts and mechanical stress. For example, in construction projects, UHMW-PE is used in foundation linings and protective barriers, ensuring structures remain intact even under extreme conditions.

Superior Abrasion Resistance

One of the standout properties of UHMW-PE is its abrasion resistance. This material outperforms many other engineering plastics in environments where materials are exposed to constant wear and tear. For instance, UHMW-PE is often employed in sliding surfaces and conveyor systems where it significantly reduces wear, prolonging the lifespan of the equipment and lowering maintenance costs. This property is particularly beneficial in industrial applications where durability and reliability are paramount.

Chemical Resistance

UHMW-PE exhibits excellent chemical resistance, making it suitable for use in environments where exposure to harsh chemicals is a concern. It withstands a wide range of chemicals, including acids, bases, and organic solvents, without degrading. This resistance ensures that UHMW-PE components maintain their integrity and performance in chemical processing plants and water treatment facilities. Its ability to resist chemical attacks helps in maintaining the longevity and sustainability of infrastructure projects.

Low Friction Coefficient

Another important property of UHMW-PE is its low friction coefficient. This characteristic makes it an excellent choice for applications where smooth and efficient movement is crucial. In construction, UHMW-PE is used in sliding components and conveyor systems to reduce friction and wear, enhancing the overall efficiency and lifespan of the machinery. This property also contributes to lower energy consumption, aligning with sustainable practices.

Longevity and Sustainability

The combination of high strength, abrasion resistance, and chemical resistance ensures that UHMW-PE components have a long service life. This longevity translates to fewer replacements and repairs, reducing the overall environmental impact and contributing to the sustainability of construction projects. Moreover, UHMW-PE is recyclable, supporting a circular economy and further enhancing its appeal as an eco-friendly material.

Versatility in Construction Applications

UHMW-PE sheets are incredibly versatile and can be tailored to meet the specific requirements of various construction applications. They can be fabricated into custom components, offering solutions for diverse needs ranging from foundation linings to protective barriers. The adaptability of UHMW-PE makes it a valuable material in the construction industry, where it meets both functional and environmental criteria.

Future Trends in Sustainable Construction

As the construction industry continues to evolve, the demand for sustainable materials like UHMW-PE is expected to grow. Innovations in the production and application of UHMW-PE will likely expand its use in modern architecture and green building initiatives. The focus on sustainability and environmental responsibility will drive further adoption of UHMW-PE, paving the way for more durable and eco-friendly infrastructure projects.

By incorporating UHMW-PE into construction, builders and architects can enhance the durability, efficiency, and sustainability of their projects, contributing to a greener and more resilient built environment.

Environmental Benefits of Using UHMW-PE in Construction Projects

Recyclability of UHMW-PE

Ultra-High Molecular Weight Polyethylene (UHMW-PE) is renowned for its recyclability, a crucial aspect in promoting sustainable construction practices. Unlike many traditional construction materials, UHMW-PE can be recycled at the end of its lifecycle, reducing waste and minimizing the environmental impact. This property supports the principles of a circular economy, where materials are reused and recycled to create new products, thus conserving natural resources and reducing the demand for virgin materials.

Lower Carbon Footprint

One of the significant eco-friendly benefits of UHMW-PE is its lower carbon footprint compared to traditional materials such as steel and concrete. The production process of UHMW-PE consumes less energy and generates fewer greenhouse gas emissions. This results in a smaller carbon footprint, contributing to the reduction of overall carbon emissions associated with construction projects. Utilizing materials with a lower carbon footprint is essential in combating climate change and achieving sustainability goals in the construction industry.

Long Service Life

The longevity of UHMW-PE is another environmental benefit that cannot be overlooked. Due to its high durability and resistance to wear and tear, UHMW-PE components have a prolonged service life. This durability reduces the need for frequent replacements, thereby decreasing the environmental impact associated with manufacturing, transportation, and installation of new materials. A longer service life also means fewer resources are consumed over time, aligning with the goals of sustainable construction.

Reduction in Maintenance and Repair

UHMW-PE is highly resistant to chemical, mechanical, and environmental stress, which translates to reduced maintenance and repair needs. This property leads to fewer disruptions and less frequent need for material replacement, which in turn minimizes the environmental footprint of construction projects. By decreasing the frequency and extent of maintenance, UHMW-PE helps conserve resources and reduce waste, contributing to more sustainable infrastructure.

Lightweight Nature

The lightweight nature of UHMW-PE further enhances its environmental benefits. Lighter materials require less energy for transportation and handling, reducing fuel consumption and associated greenhouse gas emissions. In comparison to heavier traditional materials like steel and concrete, UHMW-PE's lightweight properties make it a more sustainable option for construction projects, as it helps lower the overall environmental impact from logistics and installation processes.

Versatility and Adaptability

UHMW-PE is highly versatile and can be adapted for various construction applications, ranging from foundation linings to protective barriers. Its adaptability means it can replace multiple traditional materials, streamlining the construction process and reducing material waste. By using a single material for multiple purposes, construction projects can achieve greater efficiency and sustainability.

Support for Green Building Certifications

Utilizing UHMW-PE in construction projects can contribute to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These certifications recognize buildings that meet high environmental and sustainability standards. By incorporating UHMW-PE, builders and architects can enhance their projects' sustainability credentials and contribute to a healthier and more sustainable built environment.

Future Prospects of UHMW-PE in Sustainable Construction

As the construction industry continues to prioritize sustainability, the demand for eco-friendly materials like UHMW-PE is expected to grow. Innovations in the production and application of UHMW-PE will likely expand its use in modern architecture and green building initiatives. The trend towards eco-friendly and cost-effective materials will drive further adoption of UHMW-PE across various construction sectors.

By integrating UHMW-PE into construction projects, builders and architects can enhance the durability, efficiency, and sustainability of their projects, contributing to a greener and more resilient built environment.

Applications of UHMW-PE Sheets in Building Infrastructure

Foundation Linings

UHMW-PE sheets are extensively used in foundation linings due to their exceptional durability and resistance to chemical and moisture damage. In construction, the foundation is a critical element that must remain intact under various environmental conditions. Ultra-High Molecular Weight Polyethylene (UHMW-PE) provides a robust barrier that protects foundations from water ingress, chemical spills, and other contaminants. This application not only extends the life of the foundation but also reduces maintenance costs and enhances the overall stability of the structure.

Sliding Surfaces

In modern construction, sliding surfaces play a vital role in ensuring smooth and efficient operation of moving parts. UHMW-PE sheets are ideal for these applications because of their low friction coefficient. This property allows for seamless movement in components such as sliding doors, conveyor belts, and industrial machinery. The use of UHMW-PE in these settings minimizes wear and tear, leading to longer-lasting equipment and reduced downtime for repairs. Additionally, its ability to function effectively under heavy loads and varying temperatures makes it a preferred material for high-performance sliding applications.

Protective Barriers

The construction industry often requires protective barriers to safeguard structures and personnel from potential hazards. UHMW-PE sheets offer superior impact resistance, making them an excellent choice for protective barriers. These barriers are used in a variety of settings, including loading docks, impact zones, and safety guards around heavy machinery. The high impact strength of UHMW-PE ensures that these barriers can absorb significant force without breaking or deforming, providing reliable protection in demanding environments.

Wear Strips and Guide Rails

Wear strips and guide rails are essential in applications where components are in constant motion, such as in conveyor systems and manufacturing lines. UHMW-PE sheets are used to create these strips and rails due to their excellent abrasion resistance and low friction properties. This application ensures smooth movement and reduces the risk of damage to both the guiding components and the materials being processed. The durability of UHMW-PE also means that these components require less frequent replacement, contributing to lower maintenance costs and improved efficiency.

Tank and Silo Linings

In industries such as agriculture, food processing, and chemical manufacturing, the lining of tanks and silos is crucial for maintaining product quality and preventing contamination. UHMW-PE sheets are used for these linings because of their chemical resistance and non-stick properties. This ensures that the contents of the tanks and silos do not react with the lining material or adhere to it, making cleaning and maintenance easier. The use of UHMW-PE in this application also enhances the longevity of the storage units, protecting them from corrosive materials and reducing the likelihood of leaks.

Marine Applications

In marine environments, materials are exposed to harsh conditions, including saltwater corrosion, UV radiation, and physical impacts. UHMW-PE sheets are used in applications such as dock fenders, marine pile guards, and buoys due to their excellent resistance to water absorption and UV degradation. These properties ensure that UHMW-PE components remain functional and effective over long periods, even in challenging marine conditions. This application is crucial for maintaining the integrity and safety of marine infrastructure.

Industrial Chutes and Hoppers

Industrial chutes and hoppers are used to transport bulk materials in sectors such as mining, agriculture, and food processing. UHMW-PE sheets are employed in lining these chutes and hoppers because of their low friction coefficient and high wear resistance. This application ensures that materials flow smoothly through the equipment without sticking or causing excessive wear. The durability of UHMW-PE also reduces the need for frequent maintenance and replacement, improving operational efficiency and reducing downtime.

Architectural Elements

UHMW-PE is also finding its way into architectural elements due to its versatility and aesthetic possibilities. Colored UHMW-PE sheets can be used for decorative panels, wall claddings, and urban furniture. These elements not only add to the visual appeal of buildings but also provide durable, weather-resistant surfaces that require minimal maintenance. The use of UHMW-PE in architecture supports sustainable design practices by offering long-lasting and recyclable material options.

By integrating UHMW-PE sheets into various aspects of building infrastructure, construction projects can achieve enhanced durability, efficiency, and sustainability, meeting the demands of modern architecture and industrial applications.

Case Studies: Successful UHMW-PE Implementations in Construction

Bridge Construction in Canada

Project Overview

In a recent infrastructure project in Canada, Ultra-High Molecular Weight Polyethylene (UHMW-PE) was utilized in the construction of a major bridge. The bridge fenders and support structures were lined with UHMW-PE to enhance durability and reduce maintenance costs. This implementation was critical in ensuring the longevity of the bridge, especially given the harsh weather conditions and the mechanical stresses involved.

Outcomes and Benefits

The use of UHMW-PE in this project led to significant improvements in the bridge's overall performance. The high abrasion resistance and impact strength of UHMW-PE ensured that the fenders and support structures could withstand the constant wear and tear from traffic and environmental factors. Additionally, the chemical resistance of UHMW-PE protected the bridge components from corrosion, further extending their service life. As a result, the project saw a reduction in maintenance costs and an increase in the bridge's operational lifespan, demonstrating the material's effectiveness in demanding construction applications.

Dock Fenders in the Netherlands

Project Overview

In the Netherlands, a series of dock fenders were installed using UHMW-PE sheets. The docks, located in a busy commercial port, required materials that could endure continuous exposure to water, physical impacts from ships, and varying weather conditions. UHMW-PE was chosen for its excellent water resistance and durability.

Outcomes and Benefits

The dock fenders made from UHMW-PE performed exceptionally well, providing robust protection against the impacts of docking ships. The material's low friction coefficient facilitated smoother berthing processes, reducing the risk of damage to both the ships and the docks. Furthermore, the UV resistance of UHMW-PE ensured that the fenders maintained their structural integrity and appearance over time, despite prolonged exposure to sunlight. This project highlighted UHMW-PE's suitability for marine applications, where its properties significantly contribute to the durability and safety of the infrastructure.

Conveyor Systems in an Australian Mining Facility

Project Overview

An Australian mining facility incorporated UHMW-PE in the lining of its conveyor systems. The facility required a material that could handle the abrasive nature of the mined materials while maintaining efficient operation under heavy loads. UHMW-PE was selected for its abrasion resistance and low friction properties.

Outcomes and Benefits

The integration of UHMW-PE in the conveyor systems resulted in enhanced operational efficiency and reduced downtime. The abrasion resistance of UHMW-PE minimized wear on the conveyor belts, leading to fewer replacements and maintenance interventions. Additionally, the low friction coefficient of the material allowed for smoother movement of the mined materials, increasing the overall productivity of the facility. This case study demonstrated how UHMW-PE could improve the performance and reliability of industrial equipment in harsh environments.

Protective Barriers in a New York Warehouse

Project Overview

A large warehouse in New York installed protective barriers made from UHMW-PE to safeguard its infrastructure and personnel from potential accidents involving heavy machinery. The warehouse management sought a material that offered superior impact resistance and longevity.

Outcomes and Benefits

The UHMW-PE protective barriers effectively absorbed impacts from forklifts and other heavy equipment, preventing damage to the warehouse's structural components and reducing the risk of injury to workers. The material's high impact strength ensured that the barriers remained functional and intact even after multiple impacts. Moreover, the easy maintenance and long service life of UHMW-PE reduced the overall costs associated with safety infrastructure. This project underscored the importance of UHMW-PE in enhancing workplace safety and protecting valuable assets in industrial settings.

Tank Linings in a Chemical Processing Plant in Germany

Project Overview

A chemical processing plant in Germany utilized UHMW-PE for the lining of its storage tanks. The plant needed a material that could resist the corrosive effects of various chemicals and ensure the purity of stored substances.

Outcomes and Benefits

The UHMW-PE linings provided excellent chemical resistance, preventing the tanks from corroding and maintaining the integrity of the stored chemicals. This application not only protected the tanks but also ensured that the quality of the chemicals remained uncompromised. The non-stick properties of UHMW-PE made the cleaning process more efficient, reducing downtime and maintenance costs. This case study highlighted UHMW-PE's role in maintaining safety and efficiency in chemical storage and processing applications.

By examining these real-world implementations, it is evident that UHMW-PE offers numerous benefits across various construction and industrial applications, making it a valuable material for enhancing the durability, efficiency, and sustainability of infrastructure projects.

Comparing UHMW-PE with Traditional Construction Materials

Performance Comparison with Steel

Ultra-High Molecular Weight Polyethylene (UHMW-PE) offers several performance advantages over steel in construction applications. While steel is renowned for its high tensile strength and durability, UHMW-PE excels in areas where steel's rigidity can be a disadvantage.

- Abrasion Resistance: UHMW-PE outperforms steel in abrasion resistance, making it ideal for surfaces that experience constant wear. For example, in conveyor systems and sliding surfaces, UHMW-PE provides a smoother, more durable alternative.

- Impact Resistance: UHMW-PE has superior impact strength compared to steel, absorbing impacts without deforming. This makes it suitable for protective barriers and fenders in harsh environments.

- Chemical Resistance: Unlike steel, which can corrode when exposed to certain chemicals, UHMW-PE is highly resistant to a wide range of chemicals, ensuring longer-lasting performance in chemical processing plants and water treatment facilities.

Sustainability Comparison with Wood

When comparing UHMW-PE with wood, sustainability and durability are key considerations. While wood is a natural, renewable resource, it has several limitations that UHMW-PE addresses.

- Durability: Wood is prone to rot, insect damage, and weathering, which can lead to frequent replacements and high maintenance costs. UHMW-PE is resistant to moisture, UV rays, and biological attacks, making it a more durable and low-maintenance option.

- Environmental Impact: Wood requires regular treatments with chemicals to prevent decay and insect damage, which can have negative environmental impacts. In contrast, UHMW-PE does not require such treatments and has a longer lifecycle, contributing to its sustainability.

- Recyclability: While wood can be composted, its recycling options are limited compared to UHMW-PE, which can be recycled and repurposed, supporting a circular economy.

Performance and Sustainability Comparison with Other Plastics

UHMW-PE stands out among other plastics used in construction, such as PVC, ABS, and polycarbonate, due to its unique properties.

- Abrasion and Impact Resistance: Compared to other plastics, UHMW-PE offers superior abrasion resistance and impact strength, making it suitable for demanding applications like industrial chutes and hoppers.

- Chemical Resistance: While many plastics offer good chemical resistance, UHMW-PE is particularly effective against a wide range of chemicals, ensuring its suitability in diverse environments.

- Environmental Benefits: Unlike some plastics that may release harmful substances during production or disposal, UHMW-PE is chemically inert and recyclable, making it an environmentally friendly option. Additionally, its long service life reduces the need for frequent replacements, further lowering its environmental impact.

Versatility and Adaptability

UHMW-PE's versatility allows it to be used in a wide range of construction applications. Its adaptability sets it apart from traditional materials:

- Customization: UHMW-PE can be easily fabricated into various shapes and sizes, meeting specific construction needs from foundation linings to decorative panels.

- Weight: UHMW-PE is lighter than steel and many other materials, which reduces transportation costs and makes handling easier on-site, contributing to more efficient construction processes.

Cost-Effectiveness

The cost-effectiveness of UHMW-PE is another significant advantage:

- Initial Costs: Although the initial cost of UHMW-PE may be higher than some materials, its long-term savings due to reduced maintenance and longer service life make it a cost-effective choice.

- Maintenance Costs: The low maintenance requirements of UHMW-PE, combined with its resistance to wear and environmental factors, result in lower overall costs compared to materials like wood and steel, which require frequent upkeep and repairs.

By comparing UHMW-PE with traditional construction materials, it becomes clear that UHMW-PE offers numerous benefits in terms of performance, sustainability, and cost-effectiveness. Its unique properties make it an ideal material for a wide range of construction applications, supporting modern needs for durable and environmentally friendly building solutions.

Innovative Uses of Color UHMW-PE in Modern Architecture

Aesthetic Benefits of Colored UHMW-PE

Color UHMW-PE offers unique aesthetic advantages in modern architectural designs. Its ability to be produced in various vibrant colors allows architects to integrate visually appealing elements into their projects. Unlike traditional materials, colored UHMW-PE provides flexibility in design without compromising on durability. This versatility makes it ideal for creating striking facades, decorative panels, and urban furniture that stand out.

Enhanced Visual Appeal

Incorporating colored UHMW-PE into building facades enhances the visual appeal of structures. Architects can use this material to create eye-catching patterns and color schemes that add character to buildings. The availability of a wide range of colors allows for customization to match specific design themes or branding requirements. This capability is particularly useful in commercial buildings and public spaces, where aesthetic appeal is crucial.

Functional Advantages

UHMW-PE is not only about aesthetics; it also offers significant functional benefits. Its high impact strength and abrasion resistance make it suitable for high-traffic areas. For instance, colored UHMW-PE can be used in wall claddings and protective barriers in schools, hospitals, and sports facilities, where durability and safety are paramount. The material's ability to withstand heavy use without degrading ensures long-lasting performance.

Durability and Weather Resistance

One of the key features of UHMW-PE is its weather resistance. This property is particularly advantageous for outdoor applications. Colored UHMW-PE does not fade under UV exposure and can withstand extreme weather conditions, making it perfect for outdoor furniture, playground equipment, and exterior cladding. The material retains its vibrant color and structural integrity over time, reducing the need for frequent maintenance and replacement.

Innovative Architectural Applications

Facades and Cladding

Using colored UHMW-PE in facades and cladding allows architects to play with textures and colors, creating dynamic and modern looks for buildings. The material's lightweight nature makes it easier to handle and install, reducing construction time and costs. Additionally, UHMW-PE's resistance to graffiti and easy-to-clean surface make it a practical choice for urban environments.

Interior Design Elements

Inside buildings, colored UHMW-PE can be used for decorative panels, room dividers, and accent walls. Its smooth surface and ability to be fabricated into various shapes enable designers to create innovative and aesthetically pleasing interior spaces. The material's resistance to scratches and impacts ensures that these elements remain attractive and functional for extended periods.

Sustainability and Environmental Impact

Colored UHMW-PE supports sustainable architectural practices. Its long lifespan and recyclability contribute to reducing the environmental footprint of construction projects. By choosing UHMW-PE, architects can ensure that their designs are both beautiful and eco-friendly. The material's durability reduces the need for frequent replacements, conserving resources and minimizing waste.

Case Studies and Real-World Examples

Urban Public Spaces

In urban public spaces, colored UHMW-PE has been used to create vibrant seating areas, planters, and interactive installations. For example, a public park in Europe incorporated brightly colored UHMW-PE elements into its design, making the space more engaging and visually appealing while ensuring durability against the wear and tear of public use.

Commercial Buildings

Several commercial buildings have utilized colored UHMW-PE for their exterior cladding. These projects highlight the material's ability to provide a modern, sleek look while offering superior protection against environmental elements. The color retention and low maintenance requirements make UHMW-PE an ideal choice for high-profile commercial projects.

By exploring these innovative uses of color UHMW-PE in modern architecture, it becomes clear that this material offers a unique combination of aesthetic and functional benefits. Its versatility and durability make it an excellent choice for architects looking to create sustainable, attractive, and resilient structures.

Future Trends: The Role of UHMW-PE in Green Building Initiatives

Increasing Demand for Sustainable Materials

The construction industry is experiencing a significant shift towards sustainable building practices, driven by growing environmental concerns and regulatory pressures. Ultra-High Molecular Weight Polyethylene (UHMW-PE) is emerging as a crucial material in this transformation due to its eco-friendly properties and long-term durability. As builders and architects seek materials that minimize environmental impact, UHMW-PE is poised to become a preferred choice in green building initiatives.

Enhancing Energy Efficiency

One of the major trends in sustainable construction is the focus on energy efficiency. UHMW-PE contributes to this goal through its insulative properties and ability to reduce friction in mechanical systems. For instance, using UHMW-PE in sliding components and conveyor systems can significantly lower energy consumption by minimizing resistance and wear. Additionally, its use in foundation linings and insulative panels helps improve the overall energy efficiency of buildings, aligning with the principles of passive house design.

Reducing Carbon Footprint

UHMW-PE has a lower carbon footprint compared to traditional construction materials like steel and concrete. The production process of UHMW-PE requires less energy and produces fewer greenhouse gas emissions, making it a more sustainable option. As the construction industry moves towards carbon neutrality, UHMW-PE's environmental advantages position it as a key player in reducing the carbon footprint of new developments.

Recyclability and Waste Reduction

The recyclability of UHMW-PE is a significant benefit in the context of green building practices. This material can be recycled and repurposed, supporting a circular economy. The ability to recycle UHMW-PE reduces waste and lowers the demand for virgin materials, conserving natural resources. As regulations around waste management and recycling become stricter, the use of recyclable materials like UHMW-PE will become increasingly important in construction projects.

Longevity and Durability

The long lifespan of UHMW-PE means fewer replacements and repairs, which translates to reduced resource consumption and waste over time. Its resistance to abrasion, impact, and chemicals ensures that structures built with UHMW-PE components require less frequent maintenance, contributing to the sustainability of the project. This durability is particularly valuable in harsh environments and applications where traditional materials would degrade quickly.

Innovations in UHMW-PE Applications

As the construction industry continues to innovate, new applications for UHMW-PE are being developed that enhance both the functionality and sustainability of buildings. For example, color UHMW-PE is being used in modern architectural designs to create aesthetically pleasing and durable facades. These applications not only improve the visual appeal of buildings but also contribute to their overall sustainability by using long-lasting, eco-friendly materials.

Supporting Green Building Certifications

Utilizing UHMW-PE in construction projects can help achieve green building certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These certifications recognize buildings that meet high environmental and sustainability standards. By incorporating UHMW-PE, builders can enhance their projects' sustainability credentials, ensuring compliance with international green building standards.

Case Studies and Examples

Several notable projects have already demonstrated the benefits of UHMW-PE in sustainable construction. For instance, the use of UHMW-PE in the cladding of commercial buildings has shown significant improvements in durability and maintenance efficiency. In public infrastructure, UHMW-PE has been used to enhance the longevity of bridges and docks, showcasing its potential in large-scale projects.

Future Prospects

Looking ahead, the role of UHMW-PE in green building initiatives is expected to expand. Innovations in material science will likely lead to new formulations and applications of UHMW-PE that further enhance its sustainability and performance. As the construction industry continues to prioritize environmental responsibility, UHMW-PE will play a vital role in creating buildings that are not only durable and efficient but also kind to the planet.

Common Questions and Answers about UHMW-PE and BeePlastics Customization

1. What is UHMW-PE and what are its primary benefits?

Answer: Ultra-High Molecular Weight Polyethylene (UHMW-PE) is a type of thermoplastic polyethylene known for its high abrasion resistance, impact strength, and chemical resistance. It is commonly used in applications where durability and low friction are critical, such as in conveyor systems, sliding surfaces, and protective barriers. Its benefits include a long service life, low maintenance requirements, and suitability for harsh environments.

2. How does UHMW-PE compare to traditional materials like steel and wood in construction?

Answer: UHMW-PE offers several advantages over traditional materials. Compared to steel, it provides better abrasion and impact resistance and does not corrode. Unlike wood, UHMW-PE is resistant to rot, insect damage, and weathering. Additionally, it is lightweight, recyclable, and has a lower carbon footprint, making it a more sustainable choice.

3. What are the environmental benefits of using UHMW-PE in construction projects?

Answer: UHMW-PE is environmentally friendly due to its recyclability, lower carbon footprint, and long lifespan. Its durability reduces the need for frequent replacements, which conserves resources and minimizes waste. Additionally, its resistance to chemicals and weathering makes it ideal for sustainable building practices.

4. What are the common applications of UHMW-PE sheets in construction?

Answer: UHMW-PE sheets are used in various construction applications, including foundation linings, sliding surfaces, protective barriers, wear strips, and guide rails. They are also used in tank and silo linings, marine applications, industrial chutes and hoppers, and as decorative panels in architectural designs.

5. Can BeePlastics undertake custom orders for UHMW-PE products?

Answer: Yes, BeePlastics can undertake any customization, including sample customization and batch customization. We offer flexibility in order sizes and customization options to meet specific project requirements.

6. What file formats does BeePlastics accept for custom orders?

Answer: BeePlastics accepts a variety of file formats for custom orders, including PDF and CAD. This allows us to accurately produce components based on your precise specifications.

7. Is there a minimum order quantity (MOQ) for custom orders at BeePlastics?

Answer: No, BeePlastics does not have a minimum order quantity (MOQ). We accommodate orders of all sizes, from single prototypes to large production runs, ensuring flexibility for our customers.

8. How does BeePlastics manage the production cycle for custom orders?

Answer: The production cycle at BeePlastics is tailored to the order size and complexity of the process. We communicate with our customers in real-time to provide updates on production progress, ensuring transparency and timely delivery.

9. Does BeePlastics provide samples for custom orders?

Answer: Yes, BeePlastics supports the provision of samples. The samples are free of charge; however, the customer is responsible for the shipping costs. This allows you to evaluate the quality and suitability of our materials before placing a full order.

10. What industries commonly use UHMW-PE materials from BeePlastics?

Answer: UHMW-PE materials from BeePlastics are used across various industries, including manufacturing, automotive, packaging, chemical processing, food and beverage, aerospace, sports and recreation, construction, and medical. The versatility and durability of UHMW-PE make it an ideal choice for a wide range of applications.

These common questions and answers provide a comprehensive overview of UHMW-PE's benefits and BeePlastics' customization capabilities, helping potential customers make informed decisions about their construction and industrial material needs.

Conclusion

Ultra-High Molecular Weight Polyethylene (UHMW-PE) is proving to be an invaluable material in the realm of sustainable construction. Its unique combination of durability, impact resistance, and chemical resilience makes it an ideal choice for various applications, from foundation linings and sliding surfaces to protective barriers and decorative elements. As the construction industry continues to embrace green building practices, UHMW-PE stands out not only for its performance but also for its environmental benefits.

With its recyclability, low carbon footprint, and long lifespan, UHMW-PE supports the move towards more sustainable and eco-friendly building solutions. Additionally, the innovative use of colored UHMW-PE in modern architectural designs highlights its versatility, allowing architects to create structures that are both functional and visually appealing.

At BeePlastics, we are committed to providing high-quality UHMW-PE products tailored to your specific needs. Our ability to handle customizations, accept a variety of file formats, and offer flexible order sizes ensures that you receive the best solutions for your projects. By choosing UHMW-PE, you are not only investing in superior performance but also contributing to a more sustainable future in construction.

Discover the Benefits of Custom UHMW-PE for Your Industry!

Visit our custom UHMW-PE page to learn more about the versatile applications and superior performance of our products. Don't forget to fill out the contact form at the bottom of the page to receive a personalized consultation.

-

Posted in

BeePlastic insights, construction industry, durable plastics, eco-friendly building materials, environmental impact, infrastructure projects, sustainable construction materials, UHMW-PE benefits