Revolutionizing Healthcare: The Role of Plastic CNC Machining in the Medical Industry

Unveiling the Precision Revolution: Plastic CNC Machining in the Medical Industry

In the realm of modern healthcare, the advent of Plastic CNC Machining has marked a transformative era. This innovative technique, known for its exceptional precision, has become a cornerstone in the medical industry, revolutionizing the way medical devices are crafted. In this article, we explore the profound impact of CNC machining on medical manufacturing, with a particular focus on its advancements in precision and customization.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉Plastic CNC Machining

As we delve into this technological marvel, we will uncover how CNC Machining in the Medical Industry has not only refined the production process but also enhanced the functionality and reliability of medical equipment. Join us in exploring this groundbreaking journey, where technology meets healthcare innovation.

The Evolution of CNC Machining in Medicine

A Journey from Traditional Methods to Advanced Fabrication

The landscape of medical manufacturing has undergone a significant transformation with the introduction of CNC Machining. Historically, medical device production relied on manual processes that were not only time-consuming but also lacked consistency. The advent of CNC technology brought a revolution, offering unprecedented precision and efficiency.

Milestones in Medical Machining

The evolution began with the basic CNC machines, primarily used for simple cuts and molds. As technology advanced, so did the capabilities of these machines. Today, Plastic CNC Machining is at the forefront, capable of producing intricate parts for sensitive medical devices with remarkable accuracy.

The Shift Towards Customization

In the past, the one-size-fits-all approach was common in medical tools and implants. The emergence of CNC technology has enabled the production of customized medical solutions, tailored to individual patient needs. This shift has been pivotal in enhancing the effectiveness of various medical treatments and procedures.

Advancements in Precision and Accuracy

Elevating Standards in Medical Device Manufacturing

The integration of Plastic CNC Machining into the medical industry has been a game-changer, particularly in terms of precision and accuracy. This advancement has allowed for the production of medical components with tolerances unthinkable a few decades ago.

Precision: The Heart of Medical Innovation

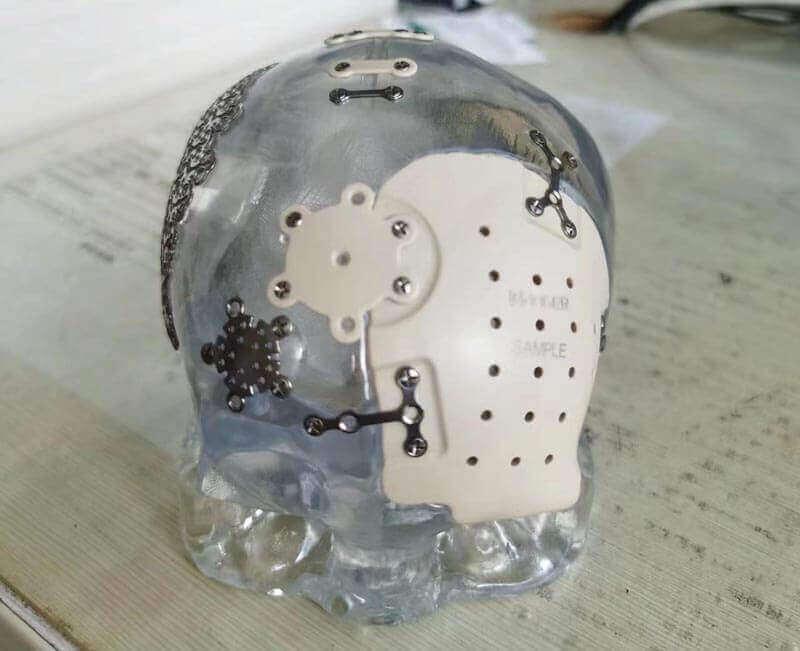

In medical device fabrication, precision is not just a requirement; it's a necessity. CNC machining has enabled the creation of intricate components for complex medical devices, such as pacemakers and orthopedic implants, with unparalleled precision.

Accuracy in Customization

Beyond general manufacturing, the accuracy of CNC machining allows for the customization of medical tools and devices. Each piece can be tailored to fit the specific needs of a patient, improving the overall effectiveness of medical treatments.

Customization: Meeting Diverse Medical Needs

Tailoring Solutions with CNC Machining

In the realm of healthcare, every patient's needs are unique, and this is where CNC machining truly shines. The capability of Plastic CNC Machining to produce custom-tailored medical components has revolutionized patient care.

Personalized Medical Devices

From prosthetics to dental implants, CNC machining allows for the creation of personalized medical devices. This customization ensures a better fit, increased comfort, and improved functionality for patients, directly enhancing their quality of life.

Responsive to Patient-Specific Requirements

The flexibility of CNC machining enables quick adaptation to specific medical requirements, making it an invaluable tool in the development of patient-specific medical solutions.

Case Studies: CNC Machining in Action

Innovative Breakthroughs in Medical Technology

To illustrate the transformative role of Plastic CNC Machining in the medical industry, let's examine a few case studies where this technology has made significant impacts.

-

Prosthetic Limbs

- Highlighting a case where CNC machining was used to create highly personalized and functional prosthetic limbs, enhancing the mobility and quality of life for patients.

-

Customized Dental Implants

- Exploring how CNC machining has enabled the production of dental implants tailored to individual patient's oral structures, leading to more effective and comfortable dental solutions.

-

Advanced Surgical Instruments

- Showcasing how precision CNC machining has facilitated the development of sophisticated surgical instruments, improving surgical outcomes and patient safety.

Impact on Patient Care and Treatment

Enhancing Healthcare with Precision Technology

The integration of Plastic CNC Machining in the medical industry has had a profound impact on patient care and treatment. This section delves into the ways CNC machining has enhanced the quality and effectiveness of medical treatments.

-

Improved Surgical Outcomes

- Discuss how the precision of CNC-machined medical tools has led to more successful surgeries with reduced risk and improved recovery times.

-

Personalized Patient Care

- Explore the impact of customized medical devices on patient comfort and treatment efficacy, emphasizing the personalized approach to patient care enabled by CNC technology.

-

Advancing Medical Research

- Highlight how CNC machining aids in medical research by enabling the creation of intricate prototypes for experimental treatments and devices.

Future Trends and Developments

Navigating Towards a Technologically Advanced Future in Medicine

As we look ahead, the future of CNC Machining in the Medical Industry appears not just promising but revolutionary. This final section explores the emerging trends and potential advancements that CNC technology is likely to bring to medical manufacturing.

-

Integration with AI and Robotics

- Discuss how the combination of CNC machining with artificial intelligence and robotics could further enhance precision and efficiency in medical device production.

-

Innovations in Biocompatible Materials

- Explore the future use of new biocompatible materials in CNC machining, which could lead to even more advanced medical implants and devices.

-

Sustainability in Medical Manufacturing

- Highlight the potential for CNC machining to contribute to more sustainable manufacturing practices in the medical industry.

Embracing a New Era in Medical Manufacturing

As we have explored, Plastic CNC Machining has undeniably transformed the landscape of the medical industry. From enhancing the precision of medical devices to enabling the customization of patient-specific solutions, this technology stands at the forefront of medical innovation. As we look towards the future, CNC machining continues to promise even greater advancements, shaping a new era of patient care and treatment. It's a journey where precision meets purpose, technology meets humanity, and every advancement brings us closer to a future of better healthcare for all.

Join the Revolution in Medical Manufacturing

Are you intrigued by the transformative impact of Plastic CNC Machining in the Medical Industry? We invite you to join us in this exciting journey. Whether you are a medical professional seeking innovative solutions or a manufacturer looking to integrate advanced CNC technologies, there is a place for you in this revolution.

Stay Informed and Engaged

Stay updated with the latest advancements in CNC machining and its applications in medical manufacturing. Subscribe to our newsletter, follow our blog, and join our community discussions to stay at the forefront of this evolving field.

Let's Shape the Future Together

Interested in exploring how CNC machining can benefit your medical manufacturing needs? Contact us today to learn more about our services and how we can collaborate to drive innovation in healthcare.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉Plastic CNC Machining

-

Posted in

accuracy, cnc machining, customization, durability, healthcare, implants, medical devices, medical equipment, plastic, prosthetics, surgical instruments