Bakelite plastic was once heralded as a groundbreaking innovation that permeated numerous industries. But over time, the limitations and disadvantages of Bakelite have become more apparent. This comprehensive guide delves into the historical context that led to Bakelite's rise and fall, while analyzing its durability issues, environmental impact, and common problems that shed light on why Bakelite is less prevalent today compared to modern plastics and advanced engineering thermoplastics.

The Historical Context: Bakelite's Rise to Fame

Bakelite was patented by Belgian-American chemist Leo Baekeland in 1907 and was the first fully synthetic plastic ever created. This was a major breakthrough at the time, as prior plastics incorporated organic materials like cellulose. Bakelite, however, was derived entirely from petroleum and coal tar residues, making it a purely industrial product and the world's first thermosetting phenolic resin.

The invention of Bakelite coincided with the rise of mass production, as Henry Ford had begun producing automobiles using assembly lines just years prior. Bakelite's heat resistance, rigidity, and electrical insulation properties lent itself nicely to mass production methods. Compared to shellac, the most common plastic of the era, Bakelite was far cheaper and could be molded into intricate detailed shapes, making it ideal for electrical insulators, automotive components, and consumer products.

Consequently, Bakelite rapidly gained popularity in the 1920s as more consumer goods shifted from natural materials to synthetic plastics. Bakelite jewelry, appliances, telephones, cameras, and even billiard balls exemplified the diverse applications of this new wonder product. For decades, Bakelite seemed to usher in a new modern age of infinite plastic possibilities, dominating the electrical and automotive industries.

Understanding Bakelite Material Composition

Bakelite is a phenol-formaldehyde resin that undergoes a thermosetting process, meaning once cured under heat and pressure, it cannot be remolded or recycled. This fundamental characteristic distinguishes it from modern thermoplastics like polypropylene, HDPE, and ABS, which can be repeatedly melted and reformed. The cross-linked molecular structure gives Bakelite its excellent electrical insulation properties and heat resistance, but also contributes to its inherent brittleness and environmental disposal challenges.

🔍 Explore Our Bakelite & Phenolic Laminate Collection

Our electrical-grade Bakelite boards and phenolic sheets are ideal for electrical insulation, vintage restoration, and precision machining projects. Available in multiple thicknesses with worldwide shipping.

Durability Concerns: Is Bakelite Built to Last?

Given that vintage Bakelite products have survived into the 21st century, it may appear that Bakelite has stood the test of time. However, Bakelite has become increasingly brittle and prone to cracking or chipping over the decades, requiring careful handling and preservation efforts. The material's rigidity also makes it difficult to repair or mend objects if damaged, unlike more flexible modern plastics that can withstand impact stress.

While pure Bakelite maintains its solid shape and dimensional stability, it lacks the flexibility and impact resistance of many common modern plastics. Items like acrylic glass or polycarbonate can deform slightly under pressure rather than shattering, making them superior choices for applications requiring mechanical strength combined with toughness. Extended exposure to heat and UV sunlight also degrades pure Bakelite faster than more advanced engineering plastics, leading to surface discoloration and structural weakening.

Bakelite telephone cases and kitchenware may seem quite durable compared to their modern disposable counterparts. But plastics like polypropylene used in current appliances can take considerably more abuse through daily use without wear and tear over many years of operation. Modern plastics also offer better chemical resistance and can easily be recycled after disposal rather than lingering in landfills for centuries.

So while Bakelite transformed the plastics industry in its heyday and remains valuable for specific niche applications like electrical insulation boards, its long-term resilience does not always stack up to the demands of contemporary lifestyles. The brittleness of vintage Bakelite necessitates careful preservation efforts and limits its use in modern high-stress applications.

Environmental Impact: Bakelite's Ecological Footprint

Aside from durability concerns, Bakelite's environmental impact has come under increasing scrutiny as sustainable manufacturing and green living have gone mainstream in the plastics industry. Producing Bakelite requires formaldehyde, a known carcinogen and volatile organic compound (VOC) that off-gasses from Bakelite products during manufacturing and use. The petroleum-derived creation process is also energy-intensive, releasing greenhouse gases and contributing to carbon emissions.

Once discarded after use, Bakelite's thermosetting infusibility makes it extremely difficult to recycle or repurpose, unlike thermoplastics that can be reshaped and remolded repeatedly through heat processing. The cross-linked molecular structure that gives Bakelite its heat resistance also means it cannot be melted down for recycling. With no microorganisms able to decompose Bakelite's phenol-formaldehyde polymer chains, discarded Bakelite products persist in landfills for centuries after disposal, contributing to long-term plastic pollution.

Modern bioplastics like PLA (polylactic acid) have emerged as environmentally-friendly alternatives, using renewable plant-based sources instead of petrochemicals. PLA bioplastics can decompose naturally through industrial composting and expose consumers to far fewer harmful emissions when producing products. Additionally, engineering plastics like HDPE, polypropylene, and PET offer excellent recyclability rates and can be reprocessed multiple times, supporting circular economy principles. While Bakelite revolutionized the plastics industry in its time, today's quest for sustainability and environmental responsibility requires eco-conscious material options with lower carbon footprints.

High-Quality Bakelite & Phenolic Laminate Materials

While vintage Bakelite has limitations, modern phenolic laminates offer superior performance for industrial and electrical applications. Our electrical-grade Bakelite boards and phenolic insulation sheets deliver authentic quality with improved consistency.

✓ No Minimum Order Quantity | ✓ Free Standard Shipping to Select Regions | ✓ Custom CNC Machining Available

Modern Alternatives: Why Bakelite is Less Used Today

Given Bakelite's durability and environmental limitations, it's understandable why other advanced plastics have almost entirely replaced Bakelite across consumer and industrial domains. Modern thermoplastics like polypropylene (PP), polyethylene terephthalate (PET), and engineering plastics like PEEK and POM excel in versatility, cost-effectiveness, and performance characteristics that far surpass traditional Bakelite.

Polypropylene, for example, offers flexibility and impact resistance while retaining excellent heat resistance able to withstand dishwasher and microwave use without degradation. Products ranging from plastic water bottles to automotive components and medical devices utilize polypropylene for unbeatable ruggedness, chemical resistance, and insulation properties meeting today's high performance benchmarks. Its recyclability also makes it environmentally preferable to thermosetting plastics.

Meanwhile, PET provides affordable optical clarity and shatter-resistance making it ideal for drink and food containers along with myriad other translucent packaging applications. And both polypropylene and PET are highly recyclable and produce negligible emissions when manufactured using best practices and modern processing technologies, supporting sustainable manufacturing initiatives.

For applications requiring superior performance, engineering plastics like PEEK (polyetheretherketone), POM (polyoxymethylene/acetal), and PTFE (polytetrafluoroethylene) offer combinations of thermal stability, chemical resistance, mechanical strength, and precision machinability that Bakelite cannot match. These advanced materials enable innovations in aerospace, medical devices, automotive engineering, and electronics manufacturing.

While no plastic is perfect, modern polymers deliver tailored combinations of thermal stability, impact resistance, dimensional accuracy, and ease of recycling that vintage Bakelite cannot provide. Supplementary materials like fiberglass-reinforced composites and carbon fiber can further bolster strength and durability where needed. The future of plastics manufacturing lies in developing safer, more sustainable alternatives to petroleum-derived materials, with improved end-of-life options including recycling and biodegradability. However, Bakelite still maintains niche applications where its specific properties—such as electrical insulation and heat resistance—remain valuable in industrial settings.

Common Issues with Bakelite Products

Beyond the overarching disadvantages already covered, Bakelite products suffer from several specific issues that consumers, collectors, and industrial users should keep in mind when working with this vintage material:

- Discoloration and UV Degradation – Bakelite often yellows and darkens with age and extended UV exposure due to photo-oxidation of the phenolic resin. Keeping items out of direct sunlight can minimize this effect, but discoloration is essentially irreversible once it occurs.

- Brittleness and Mechanical Failure – Old Bakelite tends to become increasingly brittle and prone to cracking, chipping, or shattering if mishandled or subjected to impact stress. This is due to continued cross-linking and oxidation of the polymer over decades. Gentle handling and careful storage are required for vintage pieces.

- Noxious Fumes and Formaldehyde Off-Gassing – Heating Bakelite products or machining them can release formaldehyde fumes and phenolic vapors, posing respiratory health risks and eye irritation. Use proper ventilation, respiratory protection, and caution when handling Bakelite near heat sources or during fabrication processes.

- Asbestos Contamination in Vintage Stock - Some vintage Bakelite manufactured before the 1980s incorporated asbestos fibers as reinforcement, which can cause mesothelioma, lung cancer, and asbestosis if inhaled. Always wear appropriate PPE (personal protective equipment) including respirators when machining old Bakelite stock, and have materials tested if asbestos is suspected.

- Flammability and Fire Hazards – Bakelite is combustible and burns rapidly at high temperatures (above 300°C), releasing toxic smoke containing phenol and formaldehyde. While it has some fire resistance compared to many thermoplastics, it does not meet modern flame retardancy standards. Keep fire extinguishers accessible when working with Bakelite.

- Repair Difficulties and Irreversibility – Once broken, cracked, or damaged, Bakelite cannot be reliably repaired, welded, or re-molded due to its thermosetting nature. Unlike thermoplastics which can be heat-welded or solvent-bonded, Bakelite repairs are typically limited to mechanical fastening or adhesive bonding with limited strength. Replacement parts or complete replacement may be the only viable option.

- Limited Color Options – Bakelite is typically available only in dark colors like brown, black, amber, and dark green due to the natural color of phenolic resins. This restricts design flexibility compared to modern plastics which can be produced in virtually any color.

- Moisture Absorption in Paper-Base Grades – Paper-reinforced Bakelite grades can absorb moisture over time, leading to dimensional changes, reduced electrical insulation properties, and potential delamination. Fabric-base and glass-fiber phenolic grades offer better moisture resistance.

While Bakelite heralded the plastics revolution and remains historically significant, its advantages came with numerous chemical, mechanical, and safety drawbacks. Handling genuine vintage Bakelite requires ample care, proper safety precautions, and awareness of potential hazards compared to most common modern plastics that benefit from decades of material science improvements.

The Legacy and Future of Phenolic Materials

Although Bakelite marked a pivotal breakthrough as the first fully synthetic plastic material, its characteristics reflect an early stage in polymer development preceding modern innovations in material science. While vital in its time and instrumental in launching the plastics age, Bakelite's costlier production methods, inherent brittleness, toxic component emissions, and disposal challenges make it ill-suited to today's manufacturing needs and environmental standards.

Much progress has occurred in designing affordable, durable, and eco-friendly plastics thanks to advances in polymer chemistry, processing technology, and green manufacturing initiatives. Modern phenolic laminates have been improved with better reinforcement materials, reduced formaldehyde emissions, and enhanced mechanical properties. However, for most applications, alternative materials like PEEK, POM, PTFE, polycarbonate, and other engineering thermoplastics offer superior performance characteristics.

Bakelite will remain a testament to the early strides in transforming how industries and consumers utilize plastics, even if its long-term utility has proven limited for general applications. As environmental awareness grows and regulations tighten, a balance must be found between plastics' benefits and drawbacks through responsible material selection, sustainable manufacturing practices, circular economy principles, and proper end-of-life management including recycling and safe disposal.

Custom CNC Machining for Bakelite & Modern Plastics

Our precision CNC machining, laser cutting, and engraving services deliver custom components for vintage restoration projects, electrical panels, switch plates, gears, insulators, and precision parts.

📩 Upload your technical drawing, CAD file, or photo and receive a free quote within 24 hours

🎯 Small batches welcome | No minimum order quantity | Expert DFM support included

Choosing the Right Material for Your Application

If you're working on a project that requires plastic materials with specific performance characteristics, understanding the trade-offs between different material options is crucial. While Bakelite has historical significance and niche applications in electrical insulation, modern engineering plastics often provide superior solutions:

When to Use Phenolic Laminates

- Electrical insulation (high dielectric strength)

- High-temperature environments up to 150°C

- Dimensional stability applications

- Structural compressive strength needs

- Vintage restoration projects

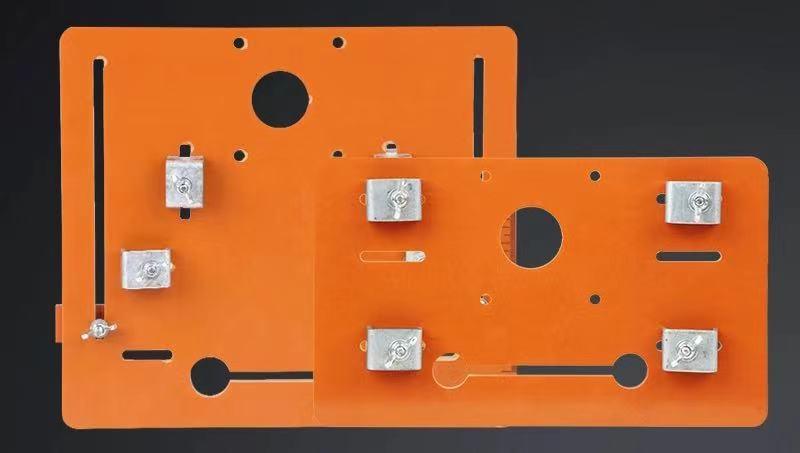

- Electrical panels and switchgear

Alternative Engineering Plastics

- PEEK - Extreme temperature (250°C+)

- POM - Precision, low friction parts

- PTFE - Chemical inertness, non-stick

- Polycarbonate - Impact, UV resistance

- HDPE/UHMWPE - Abrasion resistance

- ABS - Cost-effective fabrication

Our technical team can help you select the optimal material for your specific requirements, considering factors like operating temperature, chemical exposure, mechanical stress, electrical properties, and budget constraints. We offer free material consultation and DFM (Design for Manufacturing) analysis to ensure your project success.

Expert Plastic Fabrication Services

If you are interested in using Bakelite plastic or modern engineering plastic alternatives in your project, or want expert guidance on material selection, we're here to help. We are a professional supplier and manufacturer specializing in custom plastic processing and precision fabrication, with a professional team of engineers and state-of-the-art CNC equipment.

We can provide you with customized plastic solutions that meet your exact specifications, performance requirements, and budget constraints. Our comprehensive services include:

±0.03mm precision tolerance

Cut to your exact specifications

Cutting and engraving

Complex drilling operations

Material selection support

Prototype to volume runs

✓ No minimum order quantity required | ✓ Free standard shipping to select regions | ✓ Express shipping available

Related Products and Resources

Explore our comprehensive selection of phenolic laminates, Bakelite materials, and modern engineering plastics for your custom fabrication projects:

📦 Bakelite Products

🔧 Fabrication Services

🎯 Specialized Materials

Ready to Start Your Custom Plastic Project?

Our engineering team is ready to turn your designs into high-quality, precision-machined parts. Upload your CAD files and project requirements for a comprehensive review, competitive no-obligation quote, and expert DFM feedback.

Contact BeePlastic

Website: www.BeePlastic.com

Email: beeplastic@beeplastic.com

Business Hours: Monday to Saturday, 08:00 - 22:00