Exploring G10 and FR4: Applications, Properties, and Uses in Electronics

G10 and FR4 are two of the most widely used glass epoxy laminates in various industries, but how do they differ? In this blog, I'll take you through the key differences in G10 vs FR4, focusing on G10 mechanical strength and FR4's flame retardant properties. Whether you're working with FR4 printed circuit boards or need high-temperature insulation, understanding these materials is crucial. I'll explain how FR4's electrical insulation laminate is ideal for electronics, while G10 is perfect for mechanical parts. From moisture resistance to thermal stability, these materials excel in aerospace and industrial applications. You'll also learn about CNC machining G10 and CNC machining FR4, which ensures precision in creating durable, dielectric components. Whether you’re choosing for FR4 applications in electronics or G10 applications in heavy-duty industries, this post covers it all.

What Are G10 and FR4? Understanding Glass Epoxy Laminates

G10 and FR4 are two of the most widely used glass epoxy laminates, prized for their mechanical strength, electrical insulation, and moisture resistance. Both materials are essential in electronics, aerospace, and other high-performance industries. However, the key difference between them lies in their flame retardancy—FR4 is flame retardant, while G10 is not.

Composition of G10 and FR4

Both G10 and FR4 are made by reinforcing epoxy resin with woven glass fabric, which creates a robust and highly durable material. This glass cloth is embedded in epoxy resin through a high-pressure and high-temperature process, resulting in fiberglass composite sheets that exhibit strong dimensional stability.

G10 was originally developed as a mechanical strength laminate, making it ideal for mechanical applications that require high impact resistance and excellent wear properties. Meanwhile, FR4 evolved from G10 to meet flame resistance standards, adding brominated chemicals to make it comply with the UL 94V-0 rating.

Structural Similarities and Differences Between G10 and FR4

While G10 and FR4 share a similar base composition of glass-reinforced epoxy laminate, FR4 stands out because of its flame retardant properties. The addition of a flame-retardant additive to FR4 makes it suitable for applications where fire resistance is critical, such as in printed circuit boards (PCBs) for electronics.

On the other hand, G10 maintains high mechanical strength, making it the go-to choice for applications that don’t require flame resistance. It is often used in knife handles, aerospace components, and electrical insulation in non-flame-sensitive environments.

Core Properties of G10 and FR4

Mechanical Strength

Both G10 and FR4 provide high mechanical strength and are capable of withstanding impact, vibration, and extreme conditions. However, G10 is particularly noted for its toughness, making it ideal for high-wear environments like military and industrial applications.

Dielectric Properties

The dielectric strength of FR4 and G10 makes them perfect for electrical insulation applications. While both materials excel in electrical insulation, FR4 is preferred for applications where flame retardancy is essential, particularly in electronics and high-voltage devices.

Moisture Resistance

One of the standout features of both G10 and FR4 is their low moisture absorption, which allows them to maintain their electrical and mechanical properties even in high-humidity environments. This makes these laminates particularly useful in aerospace and marine applications, where exposure to moisture is frequent.

Understanding the similarities and differences between G10 and FR4 is crucial when selecting the right material for your project, particularly when flame resistance or mechanical durability is a key requirement.

G10 vs FR4: Key Differences in Electrical Insulation and Flame Resistance

When comparing G10 and FR4, it’s essential to consider both their electrical insulation properties and flame resistance capabilities. These two laminates are often used interchangeably in industries requiring strong electrical insulation, but the introduction of flame-retardant FR4 created a clear distinction, especially in applications that involve high temperatures or fire hazards.

Electrical Insulation Properties of G10 and FR4

Both G10 and FR4 are excellent electrical insulators, making them popular choices for applications where dielectric strength is essential. These materials can effectively prevent the flow of electric current, which is why they are used extensively in electronics, electrical enclosures, and insulation laminates.

However, FR4 takes the lead in environments where high voltage and thermal stability are critical. It’s specifically designed to provide reliable insulation even at higher temperatures, which is a common requirement in the PCB (Printed Circuit Board) industry. Thanks to its dielectric properties, FR4 excels in maintaining consistent performance under varying conditions of heat and humidity, ensuring long-term reliability in sensitive electronics.

FR4 is the industry standard for printed circuit boards, offering electrical insulation laminate properties that help reduce the risk of short circuits, fires, and electrical failure. Its stability in high-voltage environments makes it indispensable for electronic devices that require continuous operation under stressful conditions.

FR4's Flame Resistance (UL 94V-0)

One of the standout features of FR4 is its flame retardant capabilities. The UL 94V-0 rating certifies that FR4 is able to self-extinguish when exposed to flames, making it a fire-resistant material that is highly sought after in environments with fire hazards. This characteristic makes FR4 essential in the electronics industry, where flame resistance is a non-negotiable requirement.

In contrast, G10 lacks this flame retardant additive and is not suited for applications that involve significant fire risks. Instead, G10 is better for mechanical applications that require durability and high impact resistance. While FR4 is favored for PCBs and other electrical components that face flame exposure, G10 is used in non-flame-sensitive applications where high strength is the priority.

Where G10 Excels: Mechanical Strength in Non-Flame-Sensitive Applications

Although G10 doesn’t offer flame resistance, it boasts superior mechanical strength, making it ideal for high-wear environments. It has been the material of choice in aerospace and mechanical industries, where components need to withstand extreme stress and high-impact environments. G10 is commonly used in knife handles, tooling parts, and mechanical insulators, where strength and durability outweigh the need for flame resistance.

G10 retains excellent dimensional stability, even under extreme conditions. Its high impact resistance makes it valuable for industries like military equipment and aerospace, where structural integrity and shock resistance are crucial. Moreover, G10 offers flexibility in CNC machining, allowing it to be shaped into complex components while maintaining its strength and durability.

By understanding the specific differences between G10 and FR4, especially in terms of electrical insulation and flame resistance, you can make an informed decision about which material best suits your project’s requirements. Whether it's FR4 for fire-sensitive electronics or G10 for mechanical durability, these two materials offer unique advantages tailored to specific industrial needs.

Applications of G10 and FR4 in Electronics and Aerospace

Both G10 and FR4 are highly versatile glass epoxy laminates with distinct applications in electronics and aerospace. While FR4 is primarily known for its role in printed circuit boards (PCBs), G10 excels in more mechanical-heavy industries like aerospace and military equipment. The choice between these two materials often comes down to flame resistance, mechanical strength, and thermal stability, depending on the specific application.

G10 in Aerospace: High Mechanical Strength and Durability

In the aerospace industry, G10 is a favored material because of its high mechanical strength and impact resistance. It is widely used in the fabrication of aircraft components, structural parts, and high-wear parts that need to withstand extreme conditions.

G10 is highly valued for its dimensional stability, which allows it to maintain its integrity even under stressful conditions like high-speed impacts or constant vibrations. The material’s low moisture absorption also makes it ideal for applications where exposure to humidity and extreme temperatures is a factor, such as in aircraft interiors or fuselage components. Aerospace engineers often use CNC machining G10 to fabricate highly complex parts that require precise dimensions and mechanical strength.

FR4 in Electronics: The Backbone of PCB Manufacturing

On the other hand, FR4 plays a critical role in electronics, particularly in PCB manufacturing. Due to its flame retardant properties (certified by UL 94V-0), FR4 is the material of choice for printed circuit boards, which are found in virtually all electronic devices, from smartphones to industrial control systems.

The dielectric properties of FR4 make it an ideal electrical insulation laminate, preventing the risk of short circuits and electrical failure in devices that require constant operation. Moreover, FR4’s thermal stability ensures that it can endure high temperatures generated by electronic components, making it a reliable material for long-term use in high-performance electronics.

Relevance of High-Temperature Insulation in Aerospace and Electronics

Both G10 and FR4 are known for their high-temperature insulation properties, which are crucial in their respective industries. In electronics, the ability to resist heat is vital in preventing overheating in PCB components. FR4's thermal stability allows it to perform consistently under high temperatures, making it indispensable for high-voltage applications and power electronics.

In the aerospace sector, where aircraft parts can be exposed to extreme thermal environments, G10 provides excellent insulation and mechanical stability at high temperatures. It’s commonly used in thermal shielding components and structural parts that require both insulation and strength.

Moisture Resistance in Critical Applications

Moisture resistance is another critical factor in the use of G10 and FR4 in electronics and aerospace. FR4, with its excellent moisture-resistant properties, is favored for PCBs and electrical insulation in environments where humidity could compromise performance. This makes FR4 particularly effective in outdoor electronics or devices exposed to moisture.

Similarly, G10's low moisture absorption makes it suitable for aerospace applications, especially in parts that are exposed to high-altitude environments where condensation can occur. Its ability to maintain mechanical strength and insulating properties under moist conditions ensures that G10 remains durable and reliable in critical aerospace components.

Both G10 and FR4 are indispensable in their respective fields, and understanding their thermal stability, moisture resistance, and mechanical strength is key to selecting the right material for demanding electronics and aerospace applications.

The Role of CNC Machining in Shaping G10 and FR4

In high-precision industries, the use of CNC machining has revolutionized the way materials like G10 and FR4 are shaped into specialized components. Both glass epoxy laminates are prized for their durability and unique properties, making them ideal for electronics, aerospace, and industrial applications. The ability to precisely machine these materials ensures they meet the exacting standards of these industries.

CNC Machining Enhances G10 and FR4 Usability

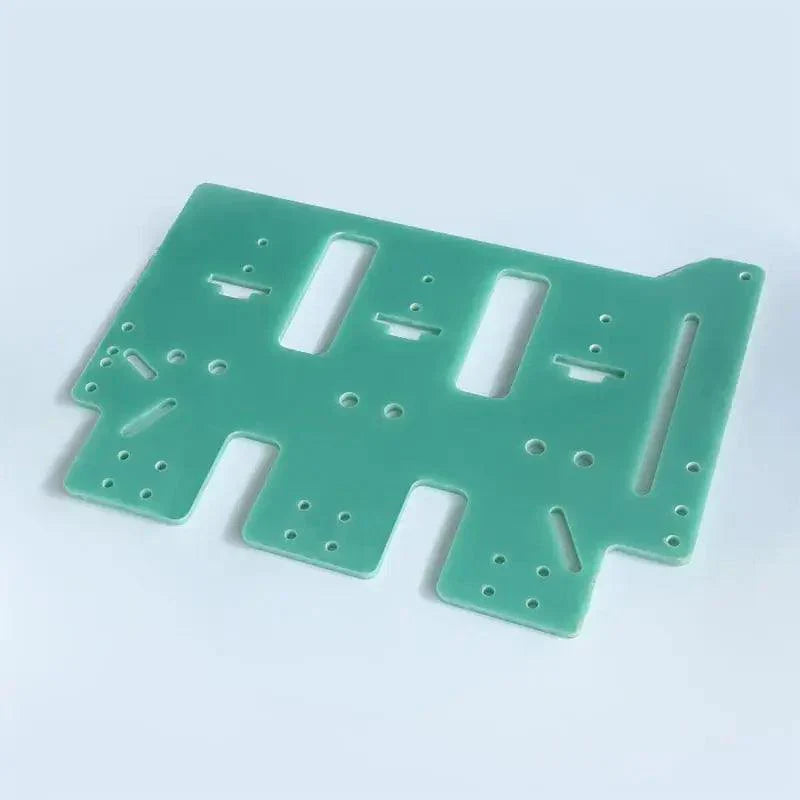

CNC machining (Computer Numerical Control) allows for precise cutting, drilling, and shaping of G10 and FR4 materials to meet specific industrial requirements. This precision is critical in industries where tight tolerances and complex geometries are necessary.

G10 and FR4 can be notoriously difficult to machine manually due to their hardness and abrasiveness, but CNC machining overcomes these challenges by using advanced tools that ensure smooth cuts and perfectly accurate dimensions. Whether it’s machining FR4 for printed circuit boards (PCBs) or CNC machining G10 for mechanical strength parts, the results are consistently reliable with minimal waste.

CNC Machining FR4 for Electrical Insulation Components

One of the most common applications of CNC machining is in shaping FR4 electrical insulation laminate for PCBs and other electrical components. FR4's flame resistance and electrical insulating properties make it the perfect material for high-voltage applications. By using CNC machining, manufacturers can produce customized FR4 parts that fit the exact needs of electronics manufacturers.

The high dielectric strength and thermal stability of FR4 are critical in ensuring that components perform consistently, even under high heat and electrical stress. With CNC machining, FR4 sheets can be turned into intricate parts, such as PCB bases, terminal strips, and switchboard components, with extreme accuracy. The precision of CNC machining ensures that these parts maintain their insulating properties and meet the strict safety standards required for electronics and electrical equipment.

CNC Machining G10 for Mechanical Strength Parts

While FR4 is commonly associated with electrical insulation, G10 is preferred for mechanical strength applications. The rigidity and impact resistance of G10 make it ideal for structural parts in industries such as aerospace, military, and industrial manufacturing. When CNC machined, G10 can be precisely shaped into parts that withstand high mechanical loads, vibrations, and impact forces.

CNC machining G10 allows for the creation of mechanical parts like knife handles, jigs, fixtures, and support structures. The high dimensional stability of G10 ensures that even in high-wear environments, the parts remain reliable and resistant to environmental factors such as humidity and chemical exposure. The versatility of G10 means it can be machined into both large structural components and small precision parts that require intricate detailing.

Advanced Capabilities of CNC Machining for G10 and FR4

The advanced capabilities of modern CNC machining equipment make it possible to shape G10 and FR4 into components with complex geometries, such as holes, slots, and angles, with consistent precision. CNC machines are equipped with multi-axis systems that allow for the simultaneous cutting of complex shapes without the need for additional manual intervention. This is particularly useful when machining FR4 for multi-layer PCBs or G10 for complex aerospace components.

CNC machining ensures that tolerances are maintained throughout the manufacturing process, which is critical for industries like electronics and aerospace, where even the smallest variations in part dimensions can lead to system failures. Additionally, CNC machining offers rapid prototyping capabilities, enabling manufacturers to quickly produce and test custom parts made from G10 and FR4 before moving into full production.

Through CNC machining, both G10 and FR4 can be transformed into high-performance components that meet the specific requirements of their respective industries, ensuring reliability, durability, and performance in even the most demanding applications.

High-Temperature Insulation and Moisture Resistance in G10 and FR4

Both G10 and FR4 excel in environments where thermal stability and moisture resistance are critical. These glass-reinforced epoxy laminates are designed to maintain their structural integrity and insulating properties even under extreme temperatures and humid conditions. This makes them ideal for applications in electronics, aerospace, and other high-performance industries where high-temperature insulation and moisture resistance are essential.

Thermal Stability in G10 and FR4

The thermal stability of both G10 and FR4 allows them to function in environments with high temperatures without degrading or losing their mechanical properties. In electronics, where components like printed circuit boards (PCBs) need to operate consistently under intense heat, FR4 provides excellent high-temperature insulation, maintaining its performance even when exposed to continuous heat.

FR4 is particularly well-suited for high-temperature applications because of its UL 94V-0 flame retardant rating, meaning it can withstand and even self-extinguish in the presence of flames. This makes FR4 a preferred choice in high-voltage electrical systems and power electronics, where both thermal stability and fire resistance are critical.

While G10 does not offer the same flame retardant properties as FR4, it remains highly effective in high-temperature environments. G10 is often used in aerospace applications, where heat resistance and mechanical strength are essential for parts exposed to friction and extreme heat. Its dimensional stability ensures that G10 components retain their shape and performance under varying temperature conditions.

High-Temperature Insulation for Critical Applications

Both G10 and FR4 exhibit superior insulating properties, making them reliable materials for thermal shielding and high-temperature insulation. In aerospace, G10 is commonly used for thermal insulators and structural parts that need to withstand extreme heat without losing their mechanical integrity. Its ability to maintain dimensional stability under heat and mechanical stress makes G10 an ideal material for high-performance environments.

On the other hand, FR4 is more widely used in electronics and electrical insulation applications due to its excellent heat resistance and flame-retardant properties. FR4 is the material of choice in PCBs, where high-temperature insulation is required to prevent heat-related failures in electronic devices. The material’s ability to handle thermal cycling—repeated exposure to high and low temperatures—makes it indispensable in environments where heat dissipation is crucial.

Moisture Resistance: Durability in Humid Environments

Both G10 and FR4 are designed to perform well in humid environments due to their low moisture absorption. In applications where exposure to moisture is a concern, such as marine or outdoor electrical systems, these materials ensure that components remain durable and insulating properties stay intact.

Moisture resistance is particularly important for FR4, which is often used in electronics that operate in high-humidity environments. FR4’s low water absorption prevents it from degrading when exposed to moisture, ensuring that electrical insulation remains effective in moisture-rich environments like power stations or outdoor transformers. Similarly, G10's water resistance allows it to be used in aerospace and marine environments, where condensation and humidity could otherwise impact the performance of components.

Performance in Extreme Conditions

When exposed to extreme conditions, both G10 and FR4 exhibit excellent durability and insulating performance. G10 is commonly used in applications that face mechanical wear and thermal cycling, where its heat resistance and impact strength are vital. FR4, on the other hand, stands out in environments where flame resistance and high-temperature insulation are required, particularly in electronics that need to function reliably under continuous thermal stress.

Both materials are essential in ensuring long-term reliability in electronics, aerospace, and marine applications where thermal insulation and moisture resistance are critical for performance.

Choosing Between G10 and FR4 for Industrial and Electronic Applications

When selecting the right laminate for your project, it’s essential to weigh the differences between G10 and FR4 based on your specific needs. Both materials are glass-reinforced epoxy laminates, but their properties make them more suited to distinct applications. By considering factors such as dielectric properties, flame resistance, and mechanical strength, you can make an informed decision about whether G10 or FR4 is the right choice for your industry.

Dielectric Properties: Electrical Insulation for Sensitive Electronics

Dielectric properties are a critical consideration when choosing between G10 and FR4, especially in applications where electrical insulation is paramount. Both materials provide excellent dielectric strength, but FR4 stands out as the preferred choice for printed circuit boards (PCBs) and other electrical components due to its ability to maintain consistent insulation even under high-voltage conditions.

FR4 is renowned for its dielectric properties, which prevent electrical current from traveling through the material, making it ideal for electronics. In contrast, G10 offers similar electrical insulation but lacks the flame retardant qualities of FR4. This makes FR4 more suitable for high-voltage or high-temperature applications, especially where safety and fire resistance are critical.

When working with high-performance electronics, FR4 is the go-to material because of its superior electrical insulation. However, G10 remains an excellent alternative in situations where flame resistance is not a requirement, but mechanical durability is.

Flame Resistance: Fire Safety in Electronics and High-Temperature Applications

Flame resistance is another major factor to consider when selecting between G10 and FR4. FR4 is designed with a flame retardant additive and meets the UL 94V-0 standard, which means it can self-extinguish when exposed to flames. This property makes FR4 ideal for electronic applications, where components are at risk of overheating or being exposed to high temperatures.

FR4's flame retardancy makes it the top choice for printed circuit boards and electrical insulation in power electronics, automotive electronics, and industrial control systems. Its ability to prevent electrical fires ensures that components made from FR4 can function reliably in high-stress environments, such as power stations or industrial automation systems.

On the other hand, G10 does not offer flame retardancy, making it less suitable for applications where fire hazards are present. However, its mechanical strength makes it a preferred choice for non-flame-sensitive environments like aerospace, military equipment, and heavy-duty industrial applications.

Mechanical Strength: Durability for High-Stress Industrial Applications

When it comes to mechanical strength, G10 surpasses FR4 due to its superior impact resistance and dimensional stability. G10 is widely used in industries that require tough, durable materials, such as aerospace, marine applications, and military components.

G10 is particularly valued for its rigidity and ability to withstand mechanical wear. It is commonly used in applications where parts are subject to constant vibration, impact, or stress, such as structural components, jigs, and fixtures. Additionally, CNC machining G10 allows for the creation of highly detailed, durable parts that retain their shape and functionality even in extreme conditions.

While FR4 also provides mechanical strength, its primary strength lies in its electrical insulation and fire resistance. It is not designed for high-impact environments like G10, making it less suitable for mechanical parts that require extreme durability.

Making the Right Choice: Industry-Specific Applications

In electronics, FR4 is the clear choice due to its flame resistance and superior dielectric properties, making it the industry standard for PCBs and other high-voltage applications. If your project involves high-temperature insulation or requires materials with flame retardant properties, FR4 should be your first consideration.

For mechanical applications where flame resistance is not required, G10 is the ideal choice. Its high mechanical strength, impact resistance, and dimensional stability make it a versatile option for industries like aerospace, military, and heavy machinery. Whether it’s for structural supports or high-impact components, G10 excels in demanding environments.

By understanding the specific requirements of your industry and weighing the dielectric properties, flame resistance, and mechanical strength of G10 and FR4, you can select the best material for your next project.

Frequently Asked Questions: G10 vs FR4 and Customization at BeePlastic

1. What is the main difference between G10 and FR4?

G10 and FR4 are both glass-reinforced epoxy laminates, but the key difference is that FR4 contains a flame-retardant additive and is UL 94V-0 rated, making it suitable for high-temperature environments and printed circuit boards. G10 lacks this flame retardancy, making it ideal for mechanical applications where flame resistance isn’t necessary.

2. Which material should I choose for high-temperature applications?

For applications that involve high temperatures or where fire resistance is critical, FR4 is the better option due to its UL 94V-0 flame-retardant rating. However, if your project requires mechanical strength but not flame resistance, G10 is a good choice.

3. Can I use G10 for printed circuit boards (PCBs)?

While G10 has excellent mechanical strength and electrical insulation, FR4 is the industry standard for PCBs because of its flame retardant properties. If fire safety is a concern, FR4 is the recommended material.

4. How does BeePlastic handle customization requests for G10 and FR4 materials?

BeePlastic offers customization services for both G10 and FR4 materials, including sample customization and batch production. We can accommodate unique project requirements, from precise CNC machining to specialized thicknesses and sizes. Whether you need parts for electronics or industrial applications, we can customize according to your specifications.

5. What file formats does BeePlastic accept for custom orders?

BeePlastic accepts a variety of file formats, including PDF and CAD, ensuring flexibility in the design and production process. Whether you have detailed blueprints or basic sketches, we can work with your files to create the right product for your needs.

6. Is there a minimum order quantity (MOQ) for custom orders at BeePlastic?

There is no minimum order quantity (MOQ) at BeePlastic. Whether you need a single sample or a large production run, we are happy to meet your needs. This makes us an ideal partner for both prototyping and full-scale production.

7. How does BeePlastic manage the production cycle for custom orders?

The production cycle at BeePlastic depends on the order volume and the complexity of the project. We provide real-time updates on the production progress, ensuring that you are kept informed throughout the entire process. This transparency helps you manage deadlines and expectations effectively.

8. Does BeePlastic provide free samples for G10 and FR4 materials?

Yes, BeePlastic offers free samples of both G10 and FR4 materials. Customers are only responsible for the shipping costs. This allows you to evaluate the material before placing a large order, ensuring that it meets your project requirements.

9. What industries commonly use G10 and FR4 materials?

FR4 is widely used in electronics, particularly for PCBs, electrical insulation, and high-voltage applications. G10 is more commonly found in aerospace, military, and industrial applications where mechanical strength and impact resistance are critical.

10. Can BeePlastic handle large-scale orders for G10 and FR4?

Yes, BeePlastic has the capacity to handle large-scale orders for both G10 and FR4 materials. Whether you need parts for a massive industrial project or continuous PCB production, we can deliver in the required quantities while maintaining the highest standards of quality.

Got questions or need a custom order? Reach out by filling in the contact form at the bottom of this page, and our team will get back to you with tailored advice. You can also explore our FR4 and G10 product range to get started on your next project today.

-

Posted in

Electrical Insulation, electronic materials, electronics industry, epoxy laminate, FR4, FR4 Fiberglass Sheets, FR4 flame resistance, FR4 insulation board, FR4 Laminates, FR4 properties, G10 Applications, G10 epoxy sheet, G10 vs FR4, High Voltage Insulation, industrial plastic, material properties, PCB material, thermoset plastic