Clear Acrylic Lightsaber Stand – Saber Holder for Force FX, Telescopic & Darksaber Replicas

Expected Delivery on - .

Free Shipping & Return

Money back guarantee

Fast & reliable support

Secure payment

Free standard shipping provided, no shipping fee required. Contact customer service for expedited shipping. Return within 30 days, duties & taxes non-refundable.

- Transparent - $34.53

- Black - $34.53

Clear Acrylic Lightsaber Stand – Saber Holder for Force FX, Telescopic & Darksaber Replicas

PRODUCT DETAILS

⚔️ Acrylic Lightsaber Display Stand – Showcase Your Laser Sword Collection with Style

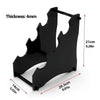

Looking for the perfect way to display your Star Wars lightsaber, Force FX saber, or custom telescopic laser sword? Our Acrylic Lightsaber Display Stand is the ultimate solution for collectors, cosplayers, and fans alike. Designed to accommodate hilts of all sizes and crafted from 4mm thick premium acrylic, this stand blends durability, clarity, and style—making it ideal for tabletop displays, bedroom shelves, or collector’s cabinets.

Available in both transparent and black options, this lightsaber stand lets your collection shine while keeping your setup organized and elegant.

🛡️ Built to Elevate Your Saber Collection

Our stand is engineered to support a wide variety of sabers—including Black Series sabers, Darksabers, custom builds, and even replica longswords and magic wands. The triple-groove design cradles your hilt safely and stylishly, making this a versatile accessory for every collector.

Whether you're showcasing a prized single saber or curating an entire gallery, this acrylic stand is your best ally for a stunning, clutter-free display.

🔍 Key Features & Benefits

✅ High-Strength 4mm Acrylic

Crafted from thick, crystal-clear acrylic for unmatched clarity and support. It won't warp or crack over time, ensuring lasting performance and a professional display finish.

✅ Universal Fit for Most Lightsabers

From standard telescopic sabers to heavier Force FX hilts, the stand supports various handle sizes and styles with a stable, non-slip base.

✅ Compact Three-Layer Display Design

With three contact points to support the hilt, this design keeps your saber secure without taking up too much space. Ideal for desks, counters, or shelves.

✅ Quick Assembly – No Tools Required

Simply peel off the protective film, slot the parts together, and you’re ready to go. Easy to disassemble and pack away when needed—great for events or conventions.

✅ Two Sleek Color Options

Choose between clear acrylic to highlight your saber or bold black to match darker-themed collectibles.

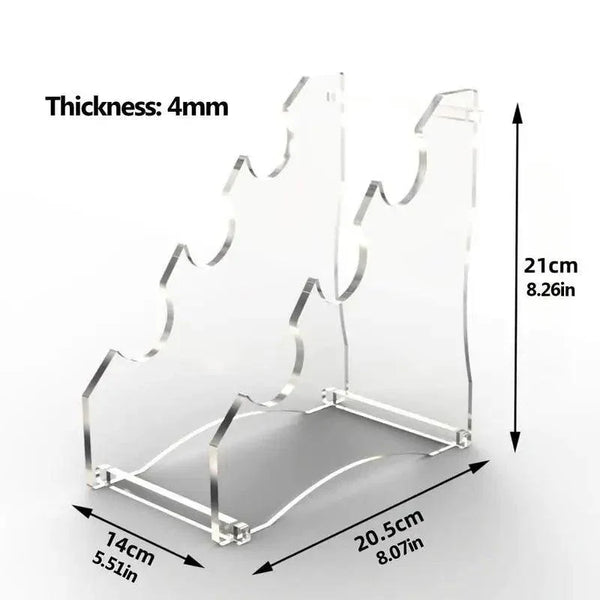

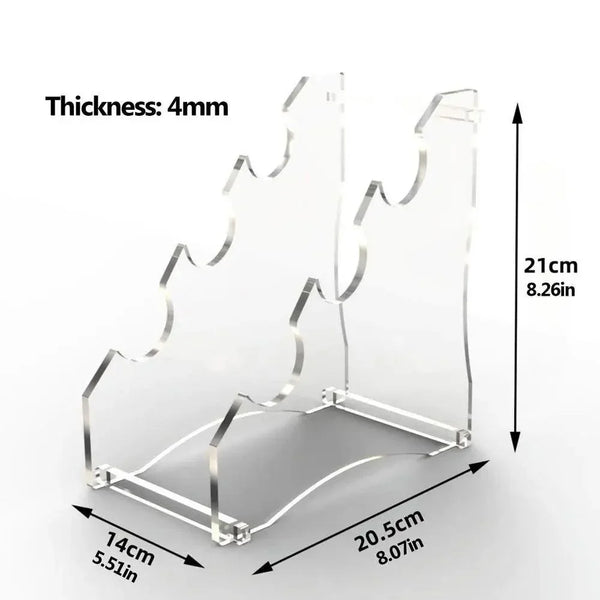

📐 Product Specifications

| Attribute | Detail |

|---|---|

| Material | Premium Acrylic (4mm thickness) |

| Color Options | Transparent / Black |

| Dimensions | Approx. 14.2 × 5.5 × 6.7 inches (L×W×H) |

| Approx. 360 × 140 × 170 mm | |

| Assembly | Tool-free standing assembly |

| Application | Lightsaber hilts, Darksabers, wands, flutes, longswords |

| Use Scenarios | Living room, bedroom, shop, convention booth, display case |

💬 Why Choose BeePlastic?

At BeePlastic, we’re more than just an acrylic stand supplier. With 15+ years of professional plastics processing experience, we provide:

-

A wide selection of plastic materials including PMMA, ABS, HDPE, PEI, POM, and more

-

Custom processing services like CNC cutting, laser engraving, and custom dimensions

-

Reliable global shipping and dedicated support

-

Transparent pricing and efficient quoting—helping you save money without compromising on quality

Whether you’re a hobbyist or a brand looking to build a product line, we’re here to support your display goals from concept to reality.

🎯 Who This Stand Is For

-

✅ Star Wars fans seeking a clean way to showcase collectibles

-

✅ Cosplayers and creators who need a reliable base for photoshoots or events

-

✅ Retailers looking for a sleek in-store display for replica props

-

✅ Hobbyists who want to organize their lightsaber collection in style

This stand is more than a prop—it’s a stage for your saber to shine.

📦 What’s Included in the Package

-

1 × Acrylic Lightsaber Display Stand (color selected)

-

1 × Protective film (to be removed before use)

-

1 × Quick assembly guide

🙋 Frequently Asked Questions

Q: Does it support heavier sabers like Darksabers or metal hilts?

A: Yes! The 4mm thick acrylic is strong enough to support most premium-grade lightsabers, including all Force FX replicas.

Q: Can I use this stand for other props?

A: Absolutely. It’s perfect for wands, flutes, katana hilts, and other long collectibles up to 2.36" (60mm) handle width.

Q: Is custom sizing or engraving available?

A: Yes! We offer full customization—sizes, materials, logos, and even multi-stand displays. Contact us now for a free quote.

Q: Do you ship internationally?

A: Yes, we ship worldwide and offer standard and express delivery options.

✨ Ready to Elevate Your Collection?

Don’t let your lightsaber sit in a drawer. Give it the display it deserves.

✅ Select your preferred color: Transparent or Black

✅ Click “Add to Cart” to place your order

✅ Or [Request a Custom Stand] if you need something tailored to your saber

Let your lightsaber shine—on your terms.

REVIEWS

SHIPPING & RETURNS

Shipping Information

Free Standard Shipping

We offer free standard shipping on all orders. Delivery time is approximately 10-25 business days, depending on your location and carrier performance. Tracking information will be provided once your order is shipped.

Express Shipping Available

Need your order faster? We offer express shipping with delivery in 4-7 business days. Express shipping fees are calculated based on your specific shipping address. To arrange express shipping, please contact our customer service team at beeplastic@beeplastic.com or via WhatsApp before placing your order. Our team will confirm the express shipping cost and process your request.

Processing Time

Standard items: Ships within 1-3 business days

Custom items: Requires 7-10 days production time before shipping

Returns & Refunds Policy

Important Notice: Returns are accepted ONLY for products with quality defects. Non-defective items cannot be returned or refunded.

Standard Items (Non-Customized Products)

Standard items without quality defects are not eligible for return or refund. If you receive a standard item with manufacturing defects or quality issues, you may request a return or replacement within 30 days of receipt.

Custom Items (Made-to-Order Products)

All customized products are NON-RETURNABLE and NON-REFUNDABLE under any circumstances. This includes any items manufactured according to your specific dimensions, shapes, quantities, or specifications. Please carefully verify your requirements before placing a custom order.

Quality Defects - How to Report

If you receive a product with quality defects, please contact us within 7 days of receipt at beeplastic@beeplastic.com. Include your order number, clear photos or videos showing the defect, and a description of the problem. Our quality team will review your case within 24 hours and provide a solution (replacement or refund) if the defect is confirmed.

Damaged During Shipping

Please inspect your order immediately upon delivery. If items are damaged during transit, contact us within 48 hours with photos of the damaged items and packaging. We will arrange a free replacement or full refund at no cost to you.

Non-Returnable Items

The following items cannot be returned: All custom-made products, items without quality defects, products damaged due to improper use or storage, and items returned without prior authorization from our team.

Refund Process

For approved returns, refunds will be processed within 10-15 business days after we receive and inspect the returned item. Refunds will be credited to your original payment method. Please allow an additional 5-7 business days for your bank or credit card company to process the refund. You will receive email confirmation once the refund is issued.

EU 14-Day Cooling-Off Period

For non-customized items shipped to EU countries, you have the right to cancel within 14 days of receipt under EU consumer protection laws. However, this right applies only to items with quality defects. Custom-made items remain non-returnable under all circumstances, as permitted by EU regulations for personalized goods.

Contact Us

For any questions about shipping or returns, please contact our customer service team:

Email: beeplastic@beeplastic.com

Response Time: Within 12 hours

We are committed to ensuring your satisfaction and will work with you to resolve any issues promptly and professionally.

CUSTOM FABRICATION

Can't Find the Right Size or Specification?

If our standard products don't match your requirements, we offer comprehensive custom fabrication services. Whether you need a specific dimension, unique shape, different thickness, or special material grade - we can manufacture it to your exact specifications.

Our Custom Capabilities

Precision Machining:

CNC machining, laser cutting, drilling, milling, and turning with ±0.03mm tolerance. Suitable for complex geometries and tight specifications.

Size Range:

Thickness: 0.5mm - 300mm

Maximum dimensions: 2000mm × 3000mm

Custom shapes: Round, square, rectangular, irregular profiles, holes, cutouts, and complex contours

Available Materials:

HDPE, PTFE, POM, Nylon, PEEK, ABS, PC, PMMA, PP, PVC, and more. Food-grade, conductive, anti-static, and flame-retardant options available.

Processing Methods:

CNC machining, laser cutting, injection molding, thermoforming, welding, and bonding. Multiple finishing options including polishing, sandblasting, and color matching.

Why Choose Custom Fabrication?

Perfect Fit: Parts manufactured to your exact specifications eliminate the need for modifications or adaptations.

No Minimum Order: Whether you need 1 piece for testing or 10,000 pieces for production, we accommodate all order sizes.

Cost Savings on Volume: Bulk custom orders receive 15-30% discount compared to purchasing multiple standard items.

Expert Technical Support: Our engineering team provides free consultation on material selection and design optimization.

Custom Order Process

Step 1: Contact us with your requirements - dimensions, material preferences, quantity, and application details. Technical drawings (PDF, CAD, DWG) are helpful but not required.

Step 2: Receive a detailed quotation within 24 hours including pricing, production lead time, and technical recommendations.

Step 3: Approve the quote and specifications. For complex projects, we can provide samples for testing before full production.

Step 4: Production begins. Typical lead time is 7-15 days depending on complexity and quantity.

Step 5: Quality inspection and shipping. Every custom piece undergoes strict dimensional checks before delivery.

Industries We Serve

Automotive components, food processing equipment, medical devices, laboratory instruments, packaging machinery, semiconductor equipment, industrial automation, and more.

Get Your Custom Quote Today

Don't see the exact size or specification you need? Let us manufacture it for you.

Contact us: beeplastic@beeplastic.com

Response time: Quote within 24 hours

What to include: Material type, dimensions, quantity, and intended application. If you have technical drawings, please attach them. If not, simply describe what you need and our team will assist you.

Not sure about material selection or specifications? No problem - our technical team will guide you through the process and recommend the best solution for your application.

RECOMMENDED PRODUCTS

Custom Plastic Fabrication

1pc to 10,000+ | ±0.03mm | No MOQ

General

HDPE

PP

PVC

ABS

Engineering

POM

Nylon

PC

PMMA

High-Performance

PEEK

PEI

PTFE

Composites

FR-4

G10

Flexible

TPU

Silicone

Why Choose BeePlastic?

Get Quote in 24h

Industries: Automotive • Medical • Food • Lab • Semiconductor

Free consultation → beeplastic@beeplastic.com

RECENTLY VIEWED PRODUCTS

24H QUOTE DELIVERY

Upload CAD, get quote in 24 hours

FREE RETURNS

30-days free return policy.

SECURED PAYMENTS

We accept all credit cards.

24/7 HELP CENTER

Dedicated 24/7 support