Mastering UHMW-PE Parts: A CNC Machining Guide for Accessory Procurement

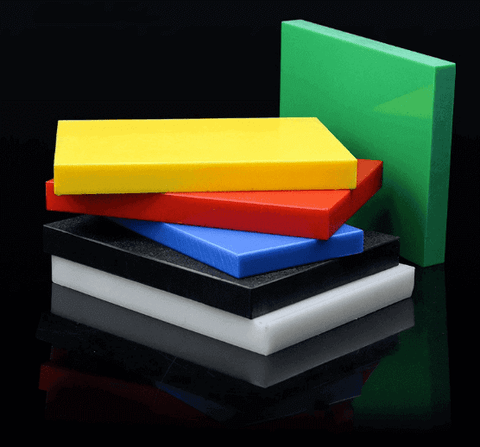

In the insightful blog post "Mastering UHMW-PE Parts: A CNC Machining Guide for Accessory Procurement," readers are invited to explore the fascinating world of UHMW-PE (Ultra High Molecular Weight Polyethylene) and its application in CNC machining for producing high-quality accessories. The post begins by delving into the Understanding of UHMW-PE Material Properties, highlighting its unique characteristics that make it an ideal choice for precision manufacturing.

We then journey through the CNC Machining Process for UHMW-PE Parts, offering a detailed look at the techniques and steps involved in shaping this versatile material into intricate accessories. The focus shifts to Design Considerations for UHMW-PE CNC Machined Parts, where readers learn about the critical aspects of designing for CNC machining, ensuring both functionality and aesthetic appeal in the final product.

For those interested in the economic aspect, the post covers Cost-Effective Procurement Strategies for UHMW-PE Machined Accessories. This section provides valuable insights into optimizing procurement processes, selecting the right suppliers, and managing costs without compromising on quality.

Lastly, the post addresses the future with Innovations and Trends in UHMW-PE CNC Machining. Here, we explore cutting-edge advancements and emerging trends in the industry, offering a glimpse into how these developments might shape the future of accessory manufacturing.

This comprehensive guide is a must-read for anyone involved in the procurement, design, or manufacturing of CNC machined accessories, providing a deep understanding of UHMW-PE and its vast potential in the world of modern manufacturing.

Understanding UHMW-PE Material Properties

In the realm of CNC machining and accessory manufacturing stands out as a material of choice due to its unique properties and versatility. This section delves into the characteristics of UHMW-PE that make it not only suitable but advantageous for CNC machining applications.

Key Characteristics of UHMW-PE

UHMW-PE is renowned for its exceptional durability and resistance to wear and abrasion. This makes it an ideal material for components that are subject to continuous or heavy use. Its ability to withstand harsh conditions without degrading ensures longevity and reliability in the final product.

Another significant attribute of UHMW-PE is its low coefficient of friction. This property is crucial in applications where parts need to slide over each other smoothly, such as in conveyor systems or gears. The reduced friction minimizes wear and tear, enhancing the efficiency and lifespan of the machined parts.

Advantages in CNC Machining

When it comes to CNC machining, UHMW-PE offers several advantages. Firstly, its machinability is excellent. UHMW-PE can be easily cut, drilled, and shaped using standard CNC equipment, allowing for precise and intricate designs. This ease of machining translates to reduced production times and costs, making it a cost-effective choice for manufacturers.

Moreover, UHMW-PE's impact resistance is a significant benefit. Parts made from this material can withstand high-impact forces without cracking or breaking, which is essential for accessories used in demanding environments.

UHMW-PE in Accessory Manufacturing

In the context of accessory manufacturing, UHMW-PE's properties open up a wide range of applications. Its chemical resistance makes it suitable for use in environments where exposure to corrosive substances is a concern. This material does not easily react with chemicals, ensuring that the parts remain intact and functional over time.

Additionally, UHMW-PE's lightweight nature compared to metals like steel or aluminum is a considerable advantage. It offers the strength and durability required for many applications while reducing the overall weight of the accessory. This aspect is particularly beneficial in automotive and aerospace industries, where weight reduction is a constant goal.

In conclusion, the unique characteristics of UHMW-PE, including its durability, low friction, machinability, impact resistance, chemical resistance, and lightweight nature, make it an excellent material for CNC machining in accessory manufacturing. Its versatility and efficiency in production make it a top choice for a wide range of applications, ensuring high-quality, durable, and efficient end products.

For more information on UHMW-PE and its applications, feel free to explore ["More about UHMW-PE"].

The CNC Machining Process for UHMW-PE Parts

Understanding the CNC machining process for UHMW-PE (Ultra High Molecular Weight Polyethylene) parts is crucial for anyone involved in the manufacturing of precision accessories. This section outlines the specific steps and techniques used in CNC machining UHMW-PE, emphasizing the precision and customization it offers.

Preparing UHMW-PE for CNC Machining

Before the actual machining process begins, it's essential to properly prepare the UHMW-PE material. This involves selecting the right grade of UHMW-PE based on the application's requirements, such as wear resistance, impact strength, or chemical resistance. The material is then cut into manageable sizes, suitable for the CNC machine.

CNC Machining Techniques for UHMW-PE

CNC machining of UHMW-PE utilizes advanced computer-controlled equipment for precise cutting and shaping. The process typically involves several key techniques:

1. CNC Milling

CNC milling is used to create complex shapes and surfaces. It involves rotating cutting tools that remove material from the UHMW-PE block to achieve the desired shape. This method is ideal for creating intricate designs with high precision.

2. CNC Turning

CNC turning is another common technique, especially for cylindrical parts. In this process, the UHMW-PE material is rotated while a cutting tool moves in a linear motion. This allows for the creation of parts with precise diameters and smooth finishes.

Ensuring Precision and Customization

One of the significant advantages of using CNC machining for UHMW-PE parts is the high level of precision it offers. CNC machines can produce parts with tight tolerances, ensuring that each piece meets exact specifications. This precision is crucial for accessories that require a perfect fit and consistent performance.

Customization is another benefit of CNC machining. With the ability to program the CNC machines, manufacturers can produce bespoke parts tailored to specific needs. This flexibility allows for the creation of unique and specialized accessories that might not be feasible with other manufacturing methods.

Finishing and Quality Control

After machining, the UHMW-PE parts often undergo various finishing processes. These may include deburring, polishing, or applying surface treatments to enhance the material's properties. Quality control is a critical final step, ensuring that each part meets the required standards and specifications.

In summary, the CNC machining process for UHMW-PE parts involves careful preparation, precise cutting and shaping techniques, and meticulous finishing and quality control. This process allows for the production of high-quality, customized accessories that meet specific requirements. For a deeper understanding of CNC machining and its applications, consider exploring ["Advanced CNC Machining Techniques"].

Design Considerations for UHMW-PE CNC Machined Parts

When designing parts for CNC machining using UHMW-PE (Ultra High Molecular Weight Polyethylene), several critical factors must be considered to ensure optimal performance and aesthetics. This section explores the key design considerations that impact the functionality and appearance of the final CNC machined accessories.

Understanding the Importance of Tolerances

1. Tolerance Selection

One of the most crucial aspects in the design phase is selecting appropriate tolerances. Tolerances refer to the permissible limit of variation in a physical dimension. For UHMW-PE parts, it's essential to balance tight tolerances for precision without over-constraining the design, which can lead to increased costs and complexity in manufacturing.

2. Impact of Tolerances on Functionality

The chosen tolerances directly affect the part's functionality. Tight tolerances are necessary for parts that must fit precisely with other components. However, overly tight tolerances can be unnecessary for less critical dimensions and can drive up production costs.

Considering Geometry in Design

1. Complexity and Machinability

The geometry of the part plays a significant role in its manufacturability. While UHMW-PE is highly machinable, overly complex geometries can pose challenges. It's important to design parts that are complex enough to meet functional requirements but simple enough to be efficiently machined.

2. Design for Manufacturing

Adopting a ["Design for Manufacturing"] approach can significantly enhance the machinability of UHMW-PE parts. This involves designing parts while keeping in mind the capabilities and limitations of CNC machining processes, leading to more efficient and cost-effective production.

Balancing Functionality and Aesthetics

1. Functional Priorities

In designing UHMW-PE parts, the primary focus should be on functionality. This includes considering the mechanical properties required, such as strength, wear resistance, and impact resistance, and ensuring the design accommodates these needs.

2. Aesthetic Considerations

While functionality is paramount, aesthetics should not be overlooked, especially for consumer-facing accessories. The design should incorporate elements that enhance the visual appeal of the part, such as smooth finishes or appealing shapes, without compromising its functional integrity.

Final Thoughts on Design

In conclusion, designing UHMW-PE parts for CNC machining involves a careful balance of tolerances, geometry, functionality, and aesthetics. By considering these factors, designers can create parts that not only meet the required specifications but also are cost-effective and visually appealing. For more insights into effective part design, exploring resources on ["Optimizing Part Design for CNC Machining"] can be highly beneficial.

Cost-Effective Procurement Strategies for UHMW-PE Machined Accessories

Procuring UHMW-PE CNC machined parts efficiently and cost-effectively is crucial for businesses looking to optimize their operations and maintain competitive advantage. This section provides insights into strategies that can be employed to achieve this, focusing on aspects like bulk ordering, supplier selection, and cost management.

Leveraging Bulk Ordering

1. Economies of Scale

One of the most effective strategies for cost reduction is leveraging economies of scale through bulk ordering. Purchasing larger quantities of UHMW-PE machined parts can significantly lower the unit cost, as manufacturers often offer discounts for larger orders. This approach not only reduces the cost per part but also ensures a steady supply of components.

2. Planning and Forecasting

Effective planning and forecasting are key to successful bulk ordering. Businesses need to assess their long-term needs accurately to avoid overstocking or shortages. Implementing a robust inventory management system can aid in making informed decisions about order quantities and frequencies.

Strategic Supplier Selection

1. Evaluating Suppliers

Choosing the right supplier is critical in procuring UHMW-PE machined parts. Factors to consider include the supplier's expertise in CNC machining, their capacity to handle your order size, quality control standards, and their track record in delivering on time.

2. Building Relationships

Developing long-term relationships with suppliers can lead to better pricing, priority service, and more flexible terms. It's beneficial to work with suppliers who are willing to understand your specific needs and collaborate closely to meet them.

Effective Cost Management

1. Total Cost of Ownership

When procuring UHMW-PE parts, consider the total cost of ownership (TCO), which includes not just the purchase price but also costs related to logistics, storage, and potential wastage. Selecting a supplier who offers the best TCO can result in significant savings over time.

2. Quality vs. Price

While cost is a crucial factor, it's important not to compromise on quality. Investing in higher-quality UHMW-PE parts can reduce the need for frequent replacements and maintenance, ultimately saving money in the long run.

In summary, cost-effective procurement of UHMW-PE CNC machined parts requires a strategic approach that includes bulk ordering, careful supplier selection, and comprehensive cost management. By considering these factors, businesses can ensure they procure high-quality parts efficiently and economically. For further insights into procurement strategies, exploring resources on ["Effective Procurement in Manufacturing"] can provide additional valuable information.

Innovations and Trends in UHMW-PE CNC Machining

The field of CNC machining for UHMW-PE (Ultra High Molecular Weight Polyethylene) parts is rapidly evolving, with new advancements and trends continually emerging. This section explores the latest innovations and future directions in CNC machining of UHMW-PE, focusing on new technologies, material enhancements, and their implications for accessory manufacturing.

Cutting-Edge Technologies in CNC Machining

1. Advanced CNC Equipment

The introduction of more advanced CNC machines has significantly impacted the machining of UHMW-PE. These machines offer greater precision, speed, and flexibility, allowing for more complex and intricate designs in accessory manufacturing.

2. Automation and AI Integration

Automation and artificial intelligence (AI) are becoming increasingly prevalent in CNC machining. These technologies enable more efficient and accurate production processes, reducing human error and enhancing overall productivity.

Material Enhancements in UHMW-PE

1. Improved Material Formulations

Recent developments in UHMW-PE formulations have led to materials with enhanced properties, such as increased strength, better wear resistance, and improved thermal stability. These advancements expand the range of applications for UHMW-PE machined parts.

2. Eco-Friendly Alternatives

Sustainability is a growing concern in manufacturing. The development of eco-friendly UHMW-PE variants, which are more recyclable or produced using greener methods, is a trend gaining traction in the industry.

Implications for Accessory Manufacturing

1. Enhanced Product Capabilities

With these advancements, manufacturers can produce UHMW-PE parts that are not only more precise and durable but also more complex in design. This opens up new possibilities in the types of accessories that can be produced, meeting more specialized and demanding requirements.

2. Cost and Efficiency Improvements

The integration of advanced technologies and improved materials can lead to significant cost savings and efficiency improvements in the production of UHMW-PE accessories. This is particularly beneficial for industries where cost and time constraints are critical factors.

Looking to the Future

The future of UHMW-PE CNC machining looks promising, with ongoing research and development poised to introduce even more innovative solutions. Staying abreast of these trends is crucial for manufacturers and businesses looking to leverage the latest in technology and materials for their products.

The field of UHMW-PE CNC machining is undergoing significant transformation, driven by technological advancements and material innovations. These changes are set to redefine the capabilities and efficiencies in accessory manufacturing. For more in-depth information on the latest in CNC machining, consider exploring resources on ["Emerging Technologies in CNC Machining"].

In conclusion, the journey through the world of UHMW-PE CNC machining reveals a landscape rich with opportunities and advancements. From understanding the unique properties of UHMW-PE and mastering its machining process to navigating the nuances of design considerations and procurement strategies, this guide has provided a comprehensive overview for those looking to excel in accessory manufacturing. The future, illuminated by ongoing innovations and trends, promises even greater possibilities in efficiency, precision, and customization. As we embrace these advancements, the potential for creating superior, cost-effective, and innovative UHMW-PE machined accessories is limitless. Whether you're a seasoned manufacturer or new to the field, staying informed and adaptable in this dynamic environment is key to success. For more insights and updates on the ever-evolving world of CNC machining, keep exploring and engaging with resources like this blog. The future of manufacturing is bright, and UHMW-PE CNC machining is at its forefront.

Join the Manufacturing Revolution!

Embrace the future of accessory manufacturing with cutting-edge UHMW-PE CNC machining. If you're ready to explore bespoke solutions and advanced techniques, we're just a message away. Get in touch now by filling out the contact form at the bottom of this page, and let's embark on a journey of innovation and excellence together!

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 UHMWPE plastic

-

Posted in

UHMW-PE machining,CNC machining,accessories,procurement,material,properties,tooling,processes