⚡ Quick Answer

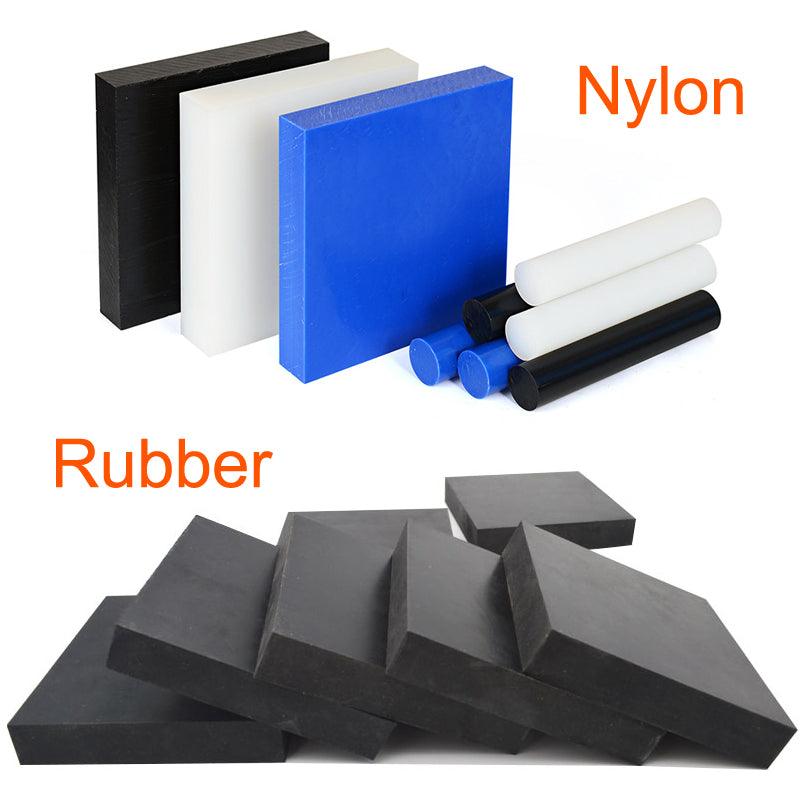

Nylon is a plastic, not rubber. It is a synthetic thermoplastic polyamide (PA) known for high tensile strength, wear resistance, and low friction coefficient. Unlike rubber's elasticity, nylon offers rigidity and durability, making it ideal for precision mechanical parts, gears, bearings, and industrial components.

Many manufacturers and engineers ask: is nylon a plastic or a type of rubber? This confusion is understandable given nylon's versatility, but the answer is clear. Nylon is a high-performance engineering plastic, not rubber. As a polyamide (PA) thermoplastic, nylon delivers exceptional mechanical properties including high strength, abrasion resistance, and dimensional stability that distinguish it from rubber's elastic characteristics.

In this comprehensive guide, we'll explore nylon's classification, properties, and applications in custom plastic processing. Whether you're selecting materials for automotive components, industrial machinery, or precision mechanical parts, understanding the differences between nylon, rubber, and other plastics will help you make informed decisions for your manufacturing needs.

🟦 Explore Premium Nylon Sheets and Rods for Industrial ApplicationsChoose from PA6 and PA66 cast or extruded nylon materials ideal for gears, rollers, bushings, and demanding mechanical parts. ✅ High Wear Resistance

|

What is Nylon? Definition and Classification of Polyamide Materials

Nylon is a high-performance synthetic polymer belonging to the polyamide (PA) family of engineering plastics. First developed by DuPont in the 1930s and commercialized in the 1940s, nylon revolutionized materials science with its unique combination of strength, durability, and versatility. The name "nylon" originally referred to a specific DuPont trademark but has since become the common term for polyamide plastics.

Nylon materials are characterized by their repeating amide linkages (-CO-NH-) in the polymer chain, which give them exceptional mechanical strength and thermal stability. Key properties include high abrasion resistance, low coefficient of friction, excellent chemical resistance, and the ability to maintain performance under elevated temperatures and demanding load conditions.

Common Types of Nylon Materials

Nylon materials are classified based on their molecular structure and monomer composition. The most common types include:

Polyamide 6 (PA6) and Polyamide 66 (PA66): These are the two most widely used nylon grades in industrial applications. PA6, synthesized from caprolactam, offers excellent impact resistance, flexibility, and easy dyeability. PA66, polymerized from hexamethylenediamine and adipic acid, provides higher tensile strength, superior heat resistance (melting point ~265°C vs 220°C for PA6), and better dimensional stability under load. Both feature linear macromolecular structures with outstanding durability and mechanical performance.

Aramid Polyimides (Aramids): These specialized nylon materials offer exceptional strength-to-weight ratios and heat resistance. Aramid fibers are significantly stiffer and stronger than standard polyamides, making them essential for high-performance applications including bulletproof vests, aerospace components, advanced composites, and reinforcement materials.

Flame-Retardant Nylon: Modified with halogenated or phosphorus-based additives, these nylon grades achieve UL94 V-0 or V-2 flame resistance ratings. They are critical for electrical equipment housings, consumer electronics, automotive electrical components, and household appliances where fire safety is paramount.

Engineering Plastics Nylon: These specialized formulations are tailored for specific industrial applications through the addition of glass fibers (GF15, GF30), carbon fibers, MoS2 lubricants, or impact modifiers. Customized grades can achieve enhanced heat resistance up to 150°C continuous use, increased stiffness, improved creep resistance, or reduced friction coefficients for bearing applications.

Understanding these nylon classifications is essential for material selection in custom plastic machining and engineering applications. Each type offers distinct advantages depending on operating conditions, mechanical loads, environmental exposure, and performance requirements.

Key Properties of Nylon Materials: Why Nylon is Plastic, Not Rubber

Nylon's classification as a thermoplastic polymer rather than an elastomer (rubber) is determined by its molecular structure and resulting physical properties. The polyamide chains in nylon are semi-crystalline with strong intermolecular hydrogen bonding, producing rigidity and dimensional stability rather than rubber's elastic recovery. Below are the critical properties that define nylon as an engineering plastic:

Mechanical Properties: Nylon exhibits excellent tensile strength (70-85 MPa for PA6, 80-95 MPa for PA66), high torsional strength, and exceptional stiffness (modulus of elasticity 2-3 GPa). Unlike rubber's low modulus and high elongation (300-800%), nylon maintains dimensional stability under load with elongation at break of only 60-100%. This rigidity makes nylon ideal for precision mechanical components including gears, bearings, bushings, and structural parts where dimensional accuracy is critical.

Wear and Friction Properties: Nylon's coefficient of friction (0.15-0.40) is significantly lower than most plastics and many metals, providing self-lubricating properties that reduce wear in sliding applications. The material's high abrasion resistance ensures long service life in bearing and gear applications, maintaining performance through millions of cycles without significant degradation.

Electrical Properties: As a good electrical insulator with dielectric strength of 15-25 kV/mm, nylon is widely used in electrical connectors, cable ties, switch housings, and wire insulation. The material can also be modified with conductive fillers or antistatic additives for applications requiring static dissipation or controlled conductivity.

Thermal Properties: Nylon materials demonstrate excellent thermal stability with continuous use temperatures of 80-110°C (PA6) to 120-140°C (PA66), and short-term exposure capability up to 150-180°C. The material resists thermal degradation and maintains mechanical properties across a wide temperature range, unlike rubber which softens significantly with heat. Nylon's crystalline structure provides dimensional stability during thermal cycling.

Chemical Resistance: Nylon resists oils, greases, fuels, hydraulic fluids, weak acids, and bases, making it suitable for automotive underhood applications and industrial machinery. However, it is hygroscopic (absorbs 1-2% moisture at equilibrium), which can affect dimensional stability and mechanical properties in humid environments.

These properties collectively demonstrate why nylon is classified as a rigid thermoplastic rather than an elastic rubber. Understanding these characteristics helps engineers and procurement specialists select appropriate materials for CNC machining, injection molding, and custom fabrication applications.

Featured Nylon Stock Materials

Machinable PA6 Nylon Sheet200x200mm black nylon board, ideal for precision CNC machining and custom parts fabrication. View Product → |

Nylon Rod 500mm (6-50mm Dia)Precision-extruded nylon rod in various diameters, perfect for turned parts and bushings. View Product → |

Nylon vs Rubber, ABS, PVC: Material Comparison for Engineers

Understanding how nylon compares to traditional materials and other plastics is essential for optimal material selection. Below we examine nylon's advantages and trade-offs versus metals, rubber, and common plastics:

Nylon vs Traditional Materials

- Steel: Nylon offers significant weight savings (density 1.13-1.15 g/cm³ vs 7.85 g/cm³ for steel) while maintaining tensile strength of 70-95 MPa. Although steel provides higher absolute strength (400+ MPa), nylon's specific strength (strength-to-weight ratio) makes it superior for applications where weight reduction is critical, such as automotive parts and portable equipment. Nylon also provides corrosion resistance and electrical insulation that steel cannot match.

- Aluminum: Like steel comparison, nylon provides weight reduction even versus aluminum (density 2.7 g/cm³). While aluminum offers better heat dissipation and maintains stiffness at higher temperatures, nylon surpasses aluminum in wear resistance, friction coefficient, and chemical resistance. At elevated temperatures (>120°C), however, nylon may experience softening and deformation where aluminum remains stable.

- Glass: Nylon is significantly tougher and more impact-resistant than glass while maintaining excellent optical clarity in certain grades. Nylon can withstand higher shear stresses and pressure loads without catastrophic failure, making it ideal for safety shields, guards, and viewing windows in industrial equipment.

Nylon vs Other Plastics and Rubber

- ABS Plastic: ABS (Acrylonitrile Butadiene Styrene) provides superior impact toughness, especially at low temperatures, and offers better dimensional stability in humid conditions since it is non-hygroscopic. However, nylon significantly exceeds ABS in tensile strength (70-95 MPa vs 40-50 MPa), wear resistance, and heat resistance (continuous use 80-120°C vs 70-80°C). For structural components, gears, and bearing applications, nylon's superior hardness and strength make it the preferred choice.

- PVC (Polyvinyl Chloride): PVC's primary advantage is cost-effectiveness and excellent chemical resistance to acids and alkalis. However, PVC has much lower strength (tensile strength 40-60 MPa), poor temperature resistance (continuous use maximum 60-70°C), and becomes brittle at low temperatures. Nylon's superior mechanical properties and temperature performance justify its higher material cost in demanding applications.

- Rubber: This is where the fundamental difference between nylon and rubber becomes apparent. Rubber (elastomers) has high flexibility, excellent elastic recovery (300-800% elongation), and superior vibration damping properties. Rubber is ideal for seals, gaskets, shock absorbers, and anti-vibration mounts. Conversely, nylon's rigidity, dimensional stability, and high abrasion resistance make it unsuitable for applications requiring elasticity but superior for load-bearing structural components. Nylon maintains shape under load where rubber would deform; rubber absorbs shock and vibration where nylon would transmit forces.

In summary, nylon's advantages include excellent hardness and strength, outstanding wear resistance, broad chemical compatibility, and diverse application versatility. However, optimal material selection requires evaluating specific operating conditions including temperature extremes, moisture exposure, chemical environment, mechanical loads, and cost constraints. In some specialized applications, alternative materials may provide better performance, which is why comprehensive material analysis is critical in engineering design.

🛠️ Need Custom Nylon Components? We Machine to Your SpecificationsFrom CNC turning and milling to laser cutting and drilling, BeePlastic provides high-precision processing of nylon parts for all industries worldwide. 📩 Upload your technical drawings and receive a detailed quote directly from our engineering team within 24 hours. 🔷 Services Include:

|

Industrial Applications: Why Nylon is Essential in Custom Plastic Processing

As a versatile engineering thermoplastic, nylon's unique combination of chemical and mechanical properties makes it indispensable across numerous industries. The material's synthesis from polyamide monomers containing amino functional groups enables excellent chemical reactivity and compatibility with various industrial processes and environments.

Nylon's advantages over traditional materials like steel and aluminum include significantly lighter weight, superior corrosion resistance, excellent electrical insulation, and self-lubricating properties. These characteristics enable direct metal replacement in applications such as gears, bearings, bushings, structural brackets, and fasteners, delivering cost savings through reduced weight, simplified manufacturing, and elimination of lubrication maintenance.

Compared to other plastics and rubber materials, nylon demonstrates significantly higher hardness and tensile strength than ABS plastic and PVC. Unlike brittle plastics that crack under stress, nylon's semi-crystalline structure provides toughness and impact resistance. While rubber excels in flexibility, shock absorption, and vibration damping applications (seals, gaskets, mountings), nylon's rigidity and dimensional stability make it superior for precision mechanical components requiring consistent performance under load.

Key industrial applications include:

- Automotive: Gears, timing chain components, fuel system parts, engine covers, air intake manifolds, under-hood electrical connectors

- Industrial Machinery: Bearing cages, conveyor rollers, wear pads, guide rails, idler pulleys, actuator components

- Electrical/Electronics: Connectors, cable ties, switch housings, circuit breaker components, coil formers

- Consumer Products: Zippers, brush bristles, fasteners, hinges, kitchen utensils, sporting goods

- Medical Devices: Surgical instruments, catheter components, tubing connectors (medical-grade formulations)

In summary, nylon's characteristics include outstanding mechanical strength, excellent wear and friction properties, good electrical insulation, and exceptional thermal stability. These properties have established nylon as a cornerstone material in custom plastic processing and modern industrial manufacturing.

Understanding the definition, classification, and properties of nylon materials—along with the key differences between nylon and other materials—enables engineers and procurement specialists to select the optimal material for specific application requirements. Proper material selection, combined with appropriate CNC machining processes and precision cutting techniques, ensures maximum performance, durability, and cost-effectiveness in final products.

🔗 Related Services & Resources

→ Custom CNC Plastic Machining Services

→ Nylon (PA6/PA66) Machining Services

→ ABS Plastic Machining Services

→ Plastic Sheet & Rod Cut-to-Size Services

→ Browse All Nylon Materials

Get Expert Support for Your Nylon Material Selection

If you're interested in this article and need more information on using nylon materials for custom production, our team at BeePlastic is ready to help. We provide technical support and professional engineering guidance tailored to your specific application requirements, helping you achieve optimal results in nylon processing and fabrication.

Whether you need to purchase nylon sheets, rods, or custom-machined components, please contact us via email or our inquiry form. Our professional engineering team responds promptly to all inquiries and will assist you in selecting high-quality, reliable nylon materials that meet your performance specifications and budget requirements.

Thank you for reading this comprehensive guide to nylon materials. We invite you to explore other related articles on our website where we continuously publish the latest industry insights and high-quality technical content to better serve our customers worldwide and contribute to the advancement of the plastics processing industry.

🎉🎉🎉 Limited Time Offer: Use code QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! Shop Nylon Materials →