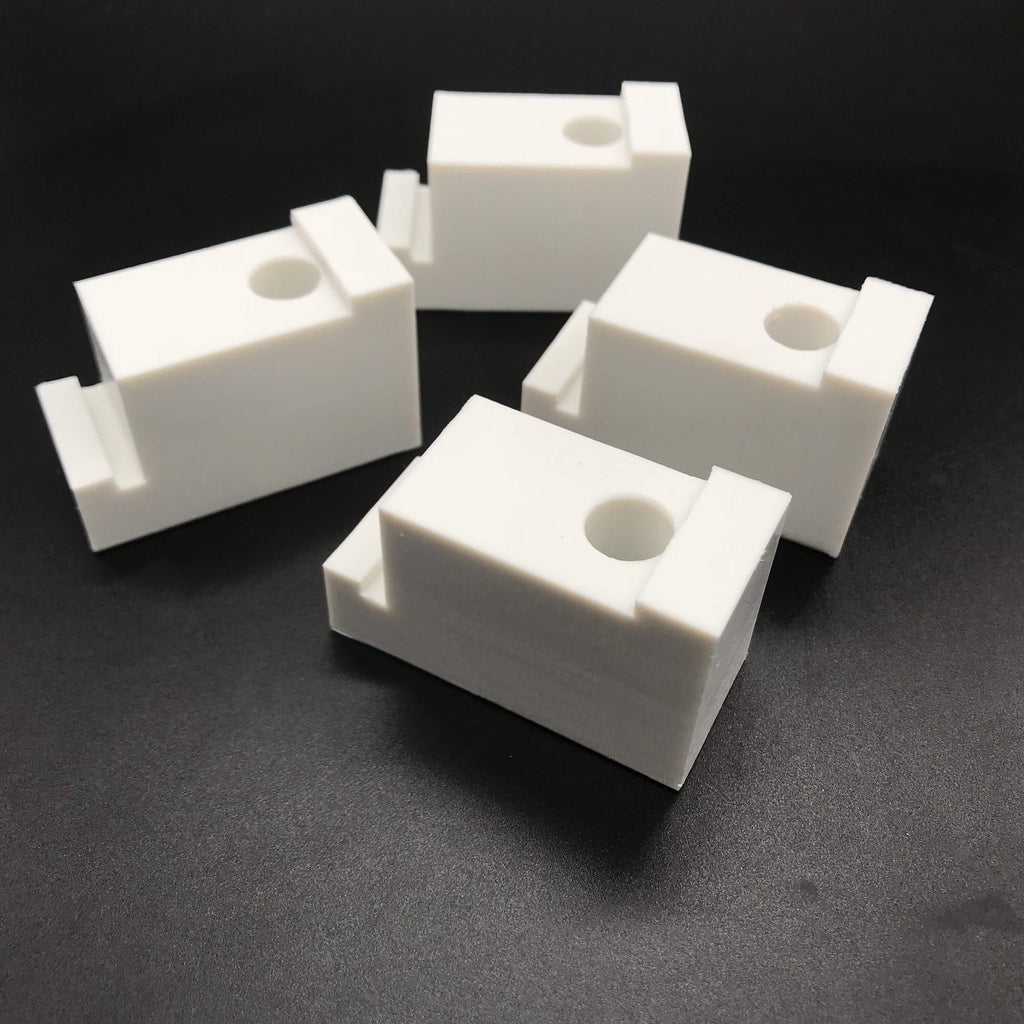

The Characteristics and Applications of ABS Plastic Material

ABS plastic material, which stands for Acrylonitrile Butadiene Styrene, is a common thermoplastic polymer that has many advantages for plastic custom processing. In this blog post, we will introduce what ABS plastic material is, its characteristics, its applications, and why you should choose beeplastic for your ABS plastic custom processing needs.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 ABS plastic

What is ABS Plastic Material?

ABS plastic material is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crisscrossed with shorter chains of poly (styrene-co-acrylonitrile).

The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. The styrene gives the plastic a shiny, impervious surface, as well as hardness, rigidity, and improved processing ease. The polybutadiene, a rubbery substance, provides toughness and ductility at low temperatures, at the cost of heat resistance and rigidity.

The Characteristics of ABS Plastic Material

ABS plastic material has many favorable characteristics that make it suitable for various applications. Some of the main characteristics are:

- High strength: ABS plastic material has high tensile strength and impact strength, which means it can withstand high forces without breaking or deforming.

- High toughness: ABS plastic material has high elongation and fracture toughness, which means it can absorb energy without cracking or shattering.

- High wear resistance: ABS plastic material has high abrasion resistance and friction coefficient, which means it can resist wear and tear from friction and rubbing.

- High corrosion resistance: ABS plastic material has high resistance to acids, alkalis, oils, greases, salts, and other chemicals, which means it can prevent rusting and deterioration from exposure to these substances.

- High temperature resistance: ABS plastic material has a high glass transition temperature of approximately 75°C , which means it can maintain its shape and properties at high temperatures without melting or softening.

- Low temperature resistance: ABS plastic material has low brittleness and low thermal expansion coefficient at low temperatures, which means it can prevent cracking and shrinking from cold exposure.

- Easy coloring: ABS plastic material can be easily colored using different pigments depending on the application, which means it can provide a variety of aesthetic options for the products.

- Easy processing: ABS plastic material can be easily processed using standard machinery and techniques such as injection molding and extrusion, which means it can reduce the cost and time of production.

The Applications of ABS Plastic Material

ABS plastic material has a wide range of applications across multiple industries due to its versatile characteristics. Some of the main applications are:

- Automotive: ABS plastic material is used for making various parts of cars such as bumpers, dashboards, door handles, wheel covers, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and temperature resistance.

- Appliances: ABS plastic material is used for making various parts of household appliances such as refrigerators, washing machines, vacuum cleaners, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and temperature resistance.

- Electronics: ABS plastic material is used for making various parts of electronic devices such as keyboards, mice, laptops, printers, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and easy coloring.

- Toys: ABS plastic material is used for making various toys such as Lego bricks, action figures, puzzles, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and easy coloring.

- Construction: ABS plastic material is used for making various parts of buildings such as pipes, fittings, panels, etc., due to its high strength, toughness, wear.

- Medical: ABS plastic material is used for making various parts of medical devices such as syringes, inhalers, blood pressure monitors, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and biocompatibility.

-

Other: ABS plastic material is also used for making various other products such as helmets, luggage, musical instruments, furniture, etc., due to its high strength, toughness, wear resistance, corrosion resistance, and easy coloring.

Why Choose beeplastic for Your ABS Plastic Custom Processing Needs?

If you are looking for a reliable and professional company that can provide you with high-quality ABS plastic custom processing services, you should choose www.beeplastic.com. Here are some of the reasons why:

- We have over 20 years of experience in plastic custom processing and have served many customers from different industries and countries.

- We have advanced equipment and technology that can handle various types of ABS plastic processing such as injection molding and extrusion.

- We have a team of skilled and experienced engineers and technicians that can design and produce ABS plastic products according to your specifications and requirements.

- We have a strict quality control system that can ensure the accuracy and consistency of our ABS plastic products.

- We have a fast and efficient delivery service that can ship your ABS plastic products to your destination in a timely manner.

- We have a competitive and reasonable pricing policy that can offer you the best value for your money.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 ABS plastic

Conclusion

ABS plastic material is a versatile thermoplastic polymer with many properties and applications that make it suitable for custom plastic fabrication. If you are interested in using ABS plastic material in your products or projects, you should contact www.beeplastic.com today. We can provide you with the best ABS plastic custom fabrication services that can meet your needs and expectations. You can email us at beeplastic@beeplastic.com for a free quote or consultation. We look forward to hearing from you!

-

Posted in

ABS, ABS CNC processing, ABS plastic, ABS plastic spray paint, ABS Rod, ABS sheet, Black ABS, engineering, plastic applications, plastic properties, thermoplastics