How Black POM Plastic Sheet Can Help You Reduce Your Environmental Impact

Are you looking for a plastic material that can offer high performance, durability and versatility for your projects or applications? Do you also want to reduce your environmental impact and achieve your sustainability goals? If yes, then you should consider using Black POM Plastic Sheet, also known as Acetal or Polyoxymethylene, for your next project or application.

Black POM Plastic Sheet is a semi-crystalline thermoplastic material that offers high strength, rigidity, hardness and good sliding and wear properties. It is also resistant to chemicals, solvents and hot water. Black POM Plastic Sheet has improved UV protection for outdoor use and can be suitable for direct contact with food.

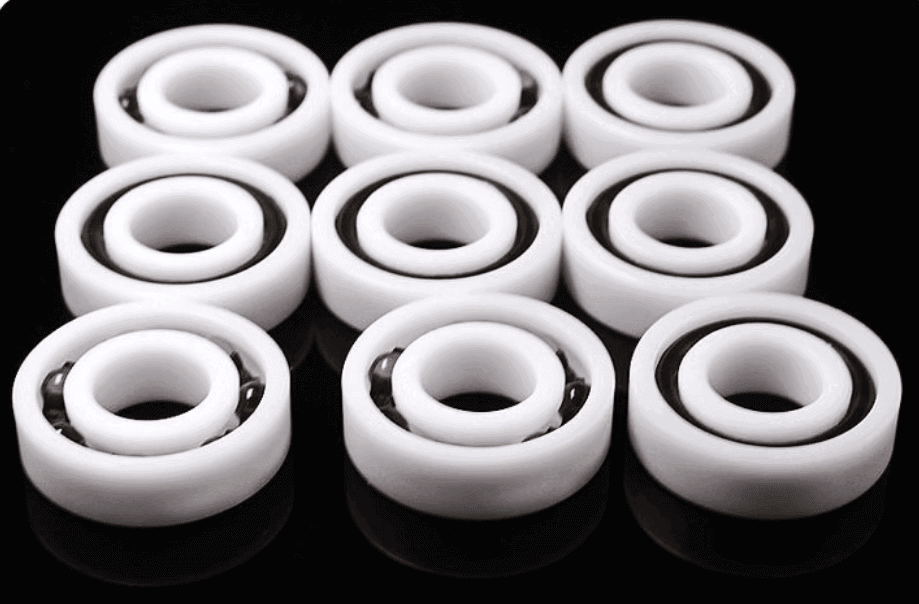

Black POM Plastic Sheet is widely used in various industries and applications, such as mechanical, automotive, electrical, food and medical engineering. It is ideal for making precision parts that require high rigidity, low friction and chemical resistance, such as gears, bearings, rollers, valves, seals and housings.

But what makes Black POM Plastic Sheet stand out from other plastics is its environmental benefits. In this article, we will discuss how Black POM Plastic Sheet can help you reduce your environmental impact in various aspects, such as energy consumption, greenhouse gas emissions, waste generation and disposal, and performance and quality during use.

Energy consumption and greenhouse gas emissions during production and processing

One of the main environmental benefits of Black POM Plastic Sheet is that it is produced from renewable methanol using a mass-balance approach. This means that fossil and renewable feedstocks are mixed in production but accounted for separately and certified via ISSCPlus-system. On a polymer basis, the Black POM Plastic Sheet option can offer up to 97% renewable content and up to 50% CO2 footprint reduction using waste-based methanol .

This is a significant improvement compared to other plastics such as PVC (Polyvinyl Chloride), PE (Polyethylene) and PP (Polypropylene), which are mainly derived from fossil fuels and have higher energy consumption and greenhouse gas emissions during production and processing. According to a study by Al-Sabri et al. , the carbon footprint of PVC is 2.6 kg CO2/kg PVC, while the carbon footprint of PE is 1.8 kg CO2/kg PE and the carbon footprint of PP is 1.7 kg CO2/kg PP. The embodied energy of PVC is 70 MJ/kg PVC, while the embodied energy of PE is 80 MJ/kg PE and the embodied energy of PP is 85 MJ/kg PP.

Therefore, by using Black POM Plastic Sheet instead of other plastics, you can save energy and reduce greenhouse gas emissions during production and processing, which can contribute to mitigating climate change and enhancing environmental protection.

Waste generation and disposal after use

Another environmental benefit of Black POM Plastic Sheet is that it is durable, recyclable and biodegradable, which can reduce the amount of waste generated and disposed after use.

Black POM Plastic Sheet has a long service life due to its high strength, rigidity, hardness and chemical resistance. It can withstand various environmental conditions such as temperature changes, moisture exposure and UV radiation without losing its functionality or quality. This means that you can use Black POM Plastic Sheet for longer periods of time without needing to replace it frequently.

- Black POM Plastic Sheet can be recycled after use by mechanical or chemical methods, which can recover the material and convert it into new products or applications. For example, Black POM Plastic Sheet can be recycled into furniture, medical devices, power tools and other plastic products by shredding, melting and molding processes. Recycling Black POM Plastic Sheet can reduce the demand for virgin material and save energy and resources.

- Black POM Plastic Sheet can also be biodegraded by microorganisms such as bacteria, fungi and algae, which can break down the polymer chains and produce carbon dioxide, water and biomass. For example, a study by Sanniyasi et al. reported that a microalga, Uronema africanum Borge, isolated from a waste plastic bag, was able to degrade low-density polyethylene (LDPE) sheet within 30 days of incubation. Biodegradation of Black POM Plastic Sheet can reduce the amount of plastic waste in landfills and oceans and prevent the negative impacts on wildlife and ecosystems.

Performance and quality during use

The last environmental benefit of Black POM Plastic Sheet is that it has high performance and quality during use, which can enhance the functionality, durability, safety and aesthetics of your products or applications.

Black POM Plastic Sheet has high strength, rigidity, hardness and sliding and wear properties, which can improve the mechanical performance of your products or applications. It can withstand high loads, stresses and impacts without breaking or deforming. It can also reduce friction and wear between moving parts and extend their service life.

Black POM Plastic Sheet has chemical resistance, UV protection and food contact suitability, which can improve the environmental performance of your products or applications. It can resist corrosion and degradation by chemicals, solvents and hot water. It can also protect your products or applications from UV radiation damage and fading. It can also be safe for direct contact with food without leaching harmful substances.

Black POM Plastic Sheet has improved UV protection for outdoor use and can be suitable for direct contact with food.

Black POM Plastic Sheet has a black color that can enhance the appearance of your products or applications. It can mask any colors or imperfections on the surface and create a uniform and elegant look. It can also match with any other colors or materials and create a contrast or harmony effect.

Therefore, by using Black POM Plastic Sheet for your products or applications, you can improve their performance and quality during use and satisfy your customers’ needs and expectations.

In conclusion, Black POM Plastic Sheet is a plastic material that can offer high performance, durability and versatility for your projects or applications. But more importantly, it can also help you reduce your environmental impact in various aspects, such as energy consumption, greenhouse gas emissions, waste generation and disposal, and performance and quality during use.

By using Black POM Plastic Sheet instead of other plastics, you can save energy and resources, reduce greenhouse gas emissions and waste generation, prevent environmental pollution and damage, enhance product functionality and quality, and achieve your sustainability goals.

If you are interested in using Black POM Plastic Sheet for your projects or applications, you can visit our website www.beeplastic.com to find out more about our products and services. We offer custom plastic fabrication with various materials, shapes and sizes to meet your needs. You can also send us an email at beeplastic@beeplastic.com to get a free quote or consultation.

Thank you for reading our article. Please feel free to leave your comments or questions below.