Canvas Phenolic Sheet (Fabric-Base) — Machinable Insulation Board, Cut-to-Size 2–50 mm

Expected Delivery on - .

Free Shipping & Return

Money back guarantee

Fast & reliable support

Secure payment

Free standard shipping provided, no shipping fee required. Contact customer service for expedited shipping. Return within 30 days, duties & taxes non-refundable.

- 6x200x300mm 1Pcs - $37.56

- 5x200x300mm 1Pcs - $35.87

- 4x200x300mm 1Pcs - $33.98

- 3x200x300mm 1Pcs - $31.33

- 50x100x200mm 1Pcs - $80.15

- 45x100x200mm 1Pcs - $72.55

- 40x100x200mm 1Pcs - $65.25

- 15x200x300mm 1Pcs - $70.49

- 12x200x300mm 1Pcs - $58.27

- 10x200x300mm 1Pcs - $50.53

- 8x200x300mm 1Pcs - $42.31

- 6x100x200mm 1Pcs - $30.63

- 5x100x200mm 1Pcs - $29.98

- 4x100x200mm 1Pcs - $29.56

- 3x100x200mm 1Pcs - $29.26

- 10x300x300mm 1Pcs - $72.49

- 8x300x300mm 1Pcs - $59.55

- 6x300x300mm 1Pcs - $46.97

- 35x100x200mm 1Pcs - $57.70

- 30x100x200mm 1Pcs - $50.53

- 25x100x200mm 1Pcs - $44.06

- 20x100x200mm 1Pcs - $37.14

- 15x100x200mm 1Pcs - $31.52

- 12x100x200mm 1Pcs - $30.17

- 10x100x200mm 1Pcs - $29.43

- 8x100x200mm 1Pcs - $30.66

- 5x200x200mm 1Pcs - $33.55

- 4x200x200mm 1Pcs - $30.81

- 3x200x200mm 1Pcs - $28.34

- 10x100x100mm 1Pcs - $27.88

- 8x100x100mm 1Pcs - $27.05

- 6x100x100mm 1Pcs - $26.88

- 5x300x300mm 1Pcs - $40.97

- 4x300x300mm 1Pcs - $34.57

- 3x300x300mm 1Pcs - $28.46

- 10x200x200mm 1Pcs - $37.35

- 8x200x200mm 1Pcs - $33.89

- 6x200x200mm 1Pcs - $32.45

- 5x100x100mm 1Pcs - $30.24

- 4x100x100mm 2Pcs - $29.05

- 3x100x100mm 2Pcs - $28.74

Canvas Phenolic Sheet (Fabric-Base) — Machinable Insulation Board, Cut-to-Size 2–50 mm

PRODUCT DETAILS

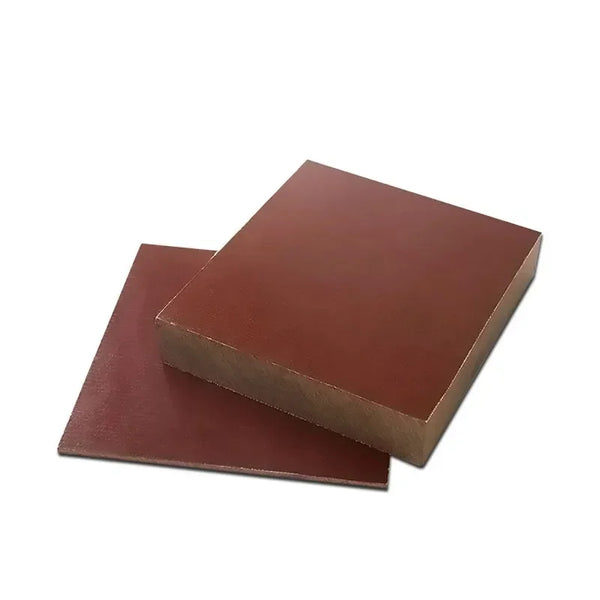

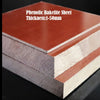

Canvas Phenolic Sheet (Fabric-Base Bakelite) | Machinable Phenolic Laminate Plate | Electrical Insulation Jig & Fixture Board | Cut-to-Size 2–50 mm (0.08–1.97 in)

Canvas Phenolic (Fabric-Base) Overview — Machinable “Bakelite” for Jigs, Fixtures, Spacer Blocks & Electrical Panels

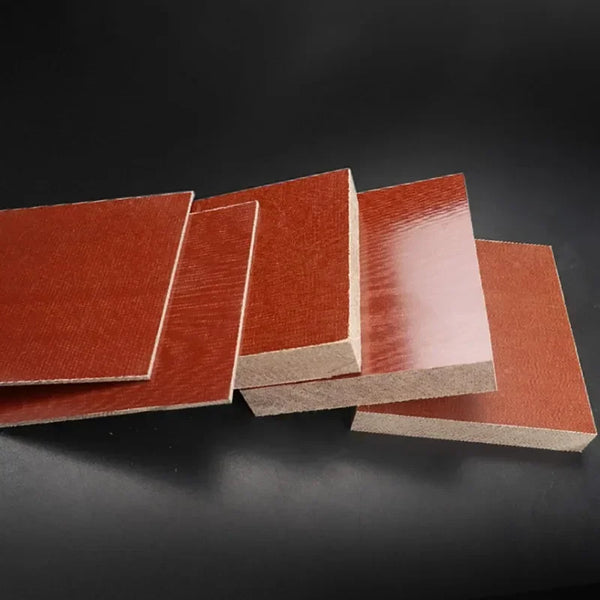

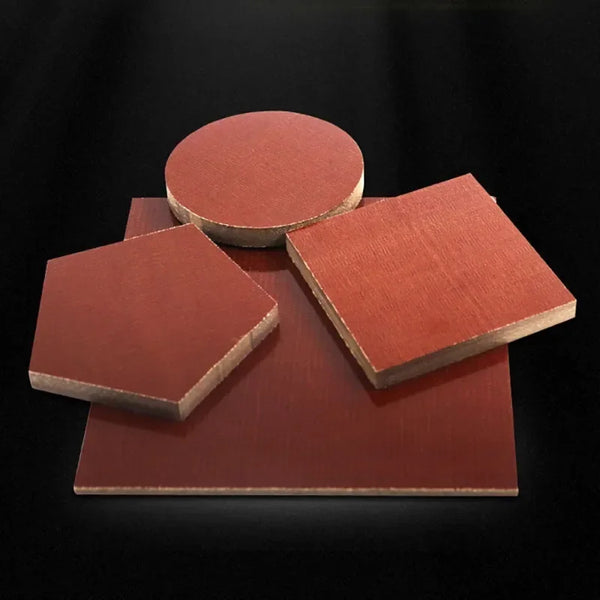

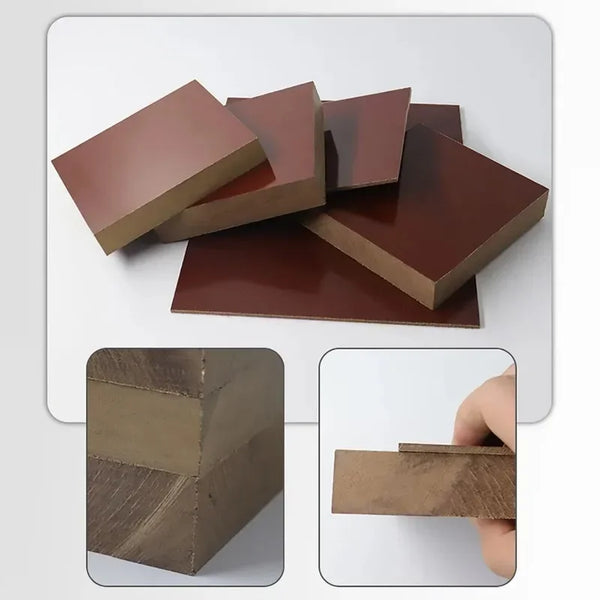

Canvas phenolic sheet (also called fabric-base phenolic laminate, cotton-cloth phenolic plate, or machining-grade “Bakelite”) is a phenolic resin laminate reinforced with woven cotton fabric. Compared with paper-base phenolic, the fabric-base grade delivers higher impact strength, better wear resistance, clean CNC machinability and dependable electrical insulation. It’s widely used for jig & fixture plates, insulating spacers/risers, tooling bases, wear pads/strips, and other machined phenolic parts.

Mechanical Strength, Electrical Insulation & CNC Machinability — Phenolic Laminate Benefits

- High mechanical strength & impact resistance → resists edge chipping under load → longer-lasting fixtures and spacer blocks.

- Reliable dielectric properties → stable insulation in shop-floor assemblies → safer switchgear panels and transformer spacers.

- Heat & wear resistance → consistent performance in production environments → less downtime and lower maintenance cost.

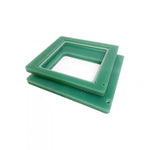

- Easy to machine (sawing, drilling, countersinking, chamfering, CNC routing/milling) → precise, repeatable fits → reduced secondary finishing and rework.

- Cut-to-size service → plates arrive ready to assemble → lower material waste & freight charges.

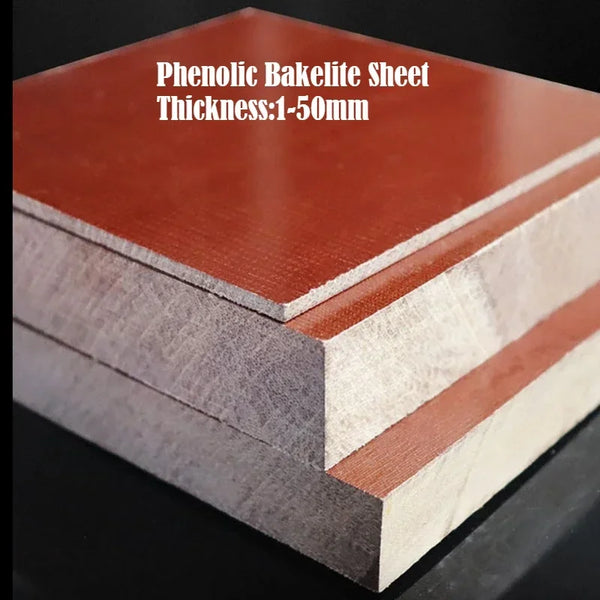

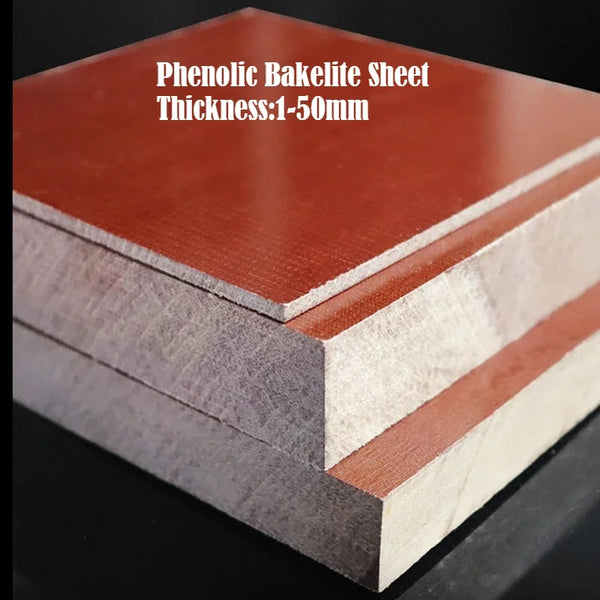

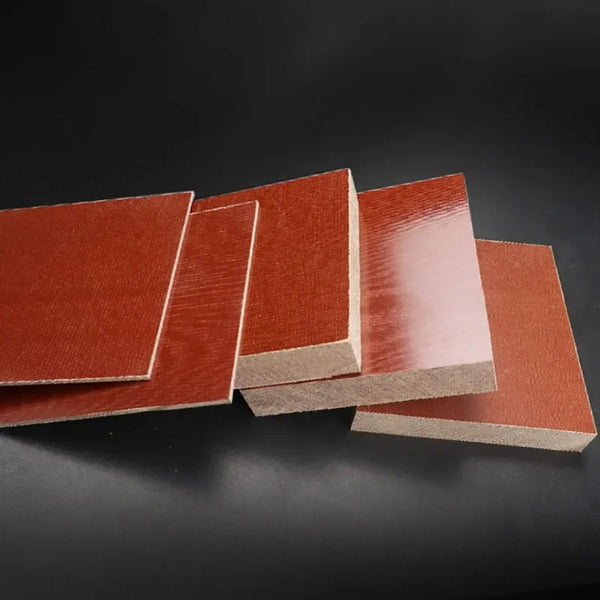

Thickness 2–50 mm & Standard Panel Sizes (mm & inch) — Cut-to-Size Canvas Phenolic Plates

- Thickness range: 2–50 mm (≈ 0.08–1.97 in)

- Common thickness (mm → in): 2 (0.08"), 3 (0.12"), 4 (0.16"), 5 (0.20"), 6 (0.24"), 8 (0.31"), 10 (0.39"), 12 (0.47"), 15 (0.59"), 20 (0.79"), 25 (0.98"), 30 (1.18"), 40 (1.57"), 50 (1.97")

- Panel sizes (mm / inch):

| Metric (mm) | Inches (approx.) |

|---|---|

| 100 × 100 | 3.94 × 3.94 in |

| 100 × 200 | 3.94 × 7.87 in |

| 100 × 300 | 3.94 × 11.81 in |

| 200 × 200 | 7.87 × 7.87 in |

| 200 × 300 | 7.87 × 11.81 in |

| 300 × 300 | 11.81 × 11.81 in |

- Packs: 1 pc or 2 pcs (bulk/wholesale available)

- Custom cuts & non-listed sizes: supported — upload a drawing or leave exact dimensions at checkout.

Upload Drawings → Free DFM & 24-Hour Quote

CNC Machining, Surface Grinding & Tolerances — Ready-to-Install Canvas Phenolic Parts

- Standard sawn tolerance: width/length ±1.5 mm (±0.06 in) for general spacer plates & bases.

- Thickness control: as-cut per sheet spec; optional surface grinding for tighter thickness & flatness when required.

- Operations: sawing, drilling, countersinking, chamfering, tapping, CNC routing/milling; light deburr recommended.

- Cost-saving design tips: keep hole-to-edge ≥ 1.5× thickness; nest multiple parts per panel to reduce scrap and freight.

Applications — Jig & Fixture Plates, Insulating Spacers/Risers, Tooling Bases, Wear Pads & Shop-Floor Insulation Boards

Use this fabric-base phenolic laminate for jigs and fixtures, insulating spacers/risers, tooling bases, wear strips/pads, and CNC-machined phenolic components in electrical and mechanical assemblies.

BeePlastic Advantage — Cut-to-Size + CNC Machining + Free DFM + Free Standard Shipping (Cost-Saving)

- One-stop materials hub: phenolic (fabric & paper), FR-4/G10, PTFE, POM, ABS, PEEK and more — match substitutes fast, reduce multi-vendor overhead.

- Custom manufacturing expertise: CNC, laser cutting, UV printing, precision surface grinding, chamfering — parts arrive install-ready.

- Customer-first pricing: free DFM check, optimized nesting to reduce scrap, protective packaging to cut freight — we proactively lower your total landed cost.

- Service & speed: responsive engineering support, flexible MOQ, free standard shipping with expedited options.

Shipping, Lead Time & Protective Packaging for Phenolic Sheets

- Lead time: typically ships in 1–3 business days; rush available.

- Shipping: free standard shipping on qualifying orders; expedited services on request.

- Packing: edge-protected cartons or wooden crate when needed to prevent corner damage on thick plates.

Canvas vs Paper Phenolic — Fabric-Base Phenolic Laminate vs Paper-Base Insulation Board

| Property | Fabric-Base (Canvas) Phenolic | Paper-Base Phenolic |

|---|---|---|

| Mechanical strength & impact | Higher; wear-resistant; ideal for fixtures | Moderate; more brittle |

| Electrical insulation | Good | Higher at similar thickness |

| Machinability | Excellent for CNC/drilling/chamfering | Adequate but chip-prone |

| Cost | Higher than paper | Lower |

If you need the lowest-cost pure insulation, see our Paper Phenolic Sheet. For fixtures, spacers and wear applications, choose fabric-base phenolic.

FAQ — Canvas Phenolic Sheet (Fabric-Base Bakelite) Sizing, Machining & Tolerances

Is this the machining-grade “Bakelite” used for fixtures?

Yes — this page is the fabric-base (canvas) phenolic, the machining-grade variant commonly chosen for jigs, fixture plates and spacer blocks.

Can you hold tight thickness and flatness?

Yes. Order standard sawn plates for general use, or request surface-ground finishing for tighter thickness/flatness when your design requires it.

Can I order in inches?

Absolutely. All options show both mm & inch. You can also submit a drawing with exact imperial dimensions.

Do you machine holes, countersinks, threads or pockets?

Yes — our machining service covers drilling, countersinking, chamfering, tapping and CNC routing/milling. Upload your drawing for a free DFM review.

How can I reduce total cost on phenolic plates?

Combine multiple parts on one panel, select the lowest workable thickness, and let us optimize nesting & packaging. We aim to minimize scrap and freight without compromising performance.

Ready to cut or machine your canvas phenolic?

Upload Drawings → Free DFM & 24-Hour Quote Talk to an Engineer

REVIEWS

SHIPPING & RETURNS

Shipping Information

Free Standard Shipping

We offer free standard shipping on all orders. Delivery time is approximately 10-25 business days, depending on your location and carrier performance. Tracking information will be provided once your order is shipped.

Express Shipping Available

Need your order faster? We offer express shipping with delivery in 4-7 business days. Express shipping fees are calculated based on your specific shipping address. To arrange express shipping, please contact our customer service team at beeplastic@beeplastic.com or via WhatsApp before placing your order. Our team will confirm the express shipping cost and process your request.

Processing Time

Standard items: Ships within 1-3 business days

Custom items: Requires 7-10 days production time before shipping

Returns & Refunds Policy

Important Notice: Returns are accepted ONLY for products with quality defects. Non-defective items cannot be returned or refunded.

Standard Items (Non-Customized Products)

Standard items without quality defects are not eligible for return or refund. If you receive a standard item with manufacturing defects or quality issues, you may request a return or replacement within 30 days of receipt.

Custom Items (Made-to-Order Products)

All customized products are NON-RETURNABLE and NON-REFUNDABLE under any circumstances. This includes any items manufactured according to your specific dimensions, shapes, quantities, or specifications. Please carefully verify your requirements before placing a custom order.

Quality Defects - How to Report

If you receive a product with quality defects, please contact us within 7 days of receipt at beeplastic@beeplastic.com. Include your order number, clear photos or videos showing the defect, and a description of the problem. Our quality team will review your case within 24 hours and provide a solution (replacement or refund) if the defect is confirmed.

Damaged During Shipping

Please inspect your order immediately upon delivery. If items are damaged during transit, contact us within 48 hours with photos of the damaged items and packaging. We will arrange a free replacement or full refund at no cost to you.

Non-Returnable Items

The following items cannot be returned: All custom-made products, items without quality defects, products damaged due to improper use or storage, and items returned without prior authorization from our team.

Refund Process

For approved returns, refunds will be processed within 10-15 business days after we receive and inspect the returned item. Refunds will be credited to your original payment method. Please allow an additional 5-7 business days for your bank or credit card company to process the refund. You will receive email confirmation once the refund is issued.

EU 14-Day Cooling-Off Period

For non-customized items shipped to EU countries, you have the right to cancel within 14 days of receipt under EU consumer protection laws. However, this right applies only to items with quality defects. Custom-made items remain non-returnable under all circumstances, as permitted by EU regulations for personalized goods.

Contact Us

For any questions about shipping or returns, please contact our customer service team:

Email: beeplastic@beeplastic.com

Response Time: Within 12 hours

We are committed to ensuring your satisfaction and will work with you to resolve any issues promptly and professionally.

CUSTOM FABRICATION

Can't Find the Right Size or Specification?

If our standard products don't match your requirements, we offer comprehensive custom fabrication services. Whether you need a specific dimension, unique shape, different thickness, or special material grade - we can manufacture it to your exact specifications.

Our Custom Capabilities

Precision Machining:

CNC machining, laser cutting, drilling, milling, and turning with ±0.03mm tolerance. Suitable for complex geometries and tight specifications.

Size Range:

Thickness: 0.5mm - 300mm

Maximum dimensions: 2000mm × 3000mm

Custom shapes: Round, square, rectangular, irregular profiles, holes, cutouts, and complex contours

Available Materials:

HDPE, PTFE, POM, Nylon, PEEK, ABS, PC, PMMA, PP, PVC, and more. Food-grade, conductive, anti-static, and flame-retardant options available.

Processing Methods:

CNC machining, laser cutting, injection molding, thermoforming, welding, and bonding. Multiple finishing options including polishing, sandblasting, and color matching.

Why Choose Custom Fabrication?

Perfect Fit: Parts manufactured to your exact specifications eliminate the need for modifications or adaptations.

No Minimum Order: Whether you need 1 piece for testing or 10,000 pieces for production, we accommodate all order sizes.

Cost Savings on Volume: Bulk custom orders receive 15-30% discount compared to purchasing multiple standard items.

Expert Technical Support: Our engineering team provides free consultation on material selection and design optimization.

Custom Order Process

Step 1: Contact us with your requirements - dimensions, material preferences, quantity, and application details. Technical drawings (PDF, CAD, DWG) are helpful but not required.

Step 2: Receive a detailed quotation within 24 hours including pricing, production lead time, and technical recommendations.

Step 3: Approve the quote and specifications. For complex projects, we can provide samples for testing before full production.

Step 4: Production begins. Typical lead time is 7-15 days depending on complexity and quantity.

Step 5: Quality inspection and shipping. Every custom piece undergoes strict dimensional checks before delivery.

Industries We Serve

Automotive components, food processing equipment, medical devices, laboratory instruments, packaging machinery, semiconductor equipment, industrial automation, and more.

Get Your Custom Quote Today

Don't see the exact size or specification you need? Let us manufacture it for you.

Contact us: beeplastic@beeplastic.com

Response time: Quote within 24 hours

What to include: Material type, dimensions, quantity, and intended application. If you have technical drawings, please attach them. If not, simply describe what you need and our team will assist you.

Not sure about material selection or specifications? No problem - our technical team will guide you through the process and recommend the best solution for your application.

RECOMMENDED PRODUCTS

Custom Plastic Fabrication

1pc to 10,000+ | ±0.03mm | No MOQ

General

HDPE

PP

PVC

ABS

Engineering

POM

Nylon

PC

PMMA

High-Performance

PEEK

PEI

PTFE

Composites

FR-4

G10

Flexible

TPU

Silicone

Why Choose BeePlastic?

Get Quote in 24h

Industries: Automotive • Medical • Food • Lab • Semiconductor

Free consultation → beeplastic@beeplastic.com

RECENTLY VIEWED PRODUCTS

24H QUOTE DELIVERY

Upload CAD, get quote in 24 hours

FREE RETURNS

30-days free return policy.

SECURED PAYMENTS

We accept all credit cards.

24/7 HELP CENTER

Dedicated 24/7 support