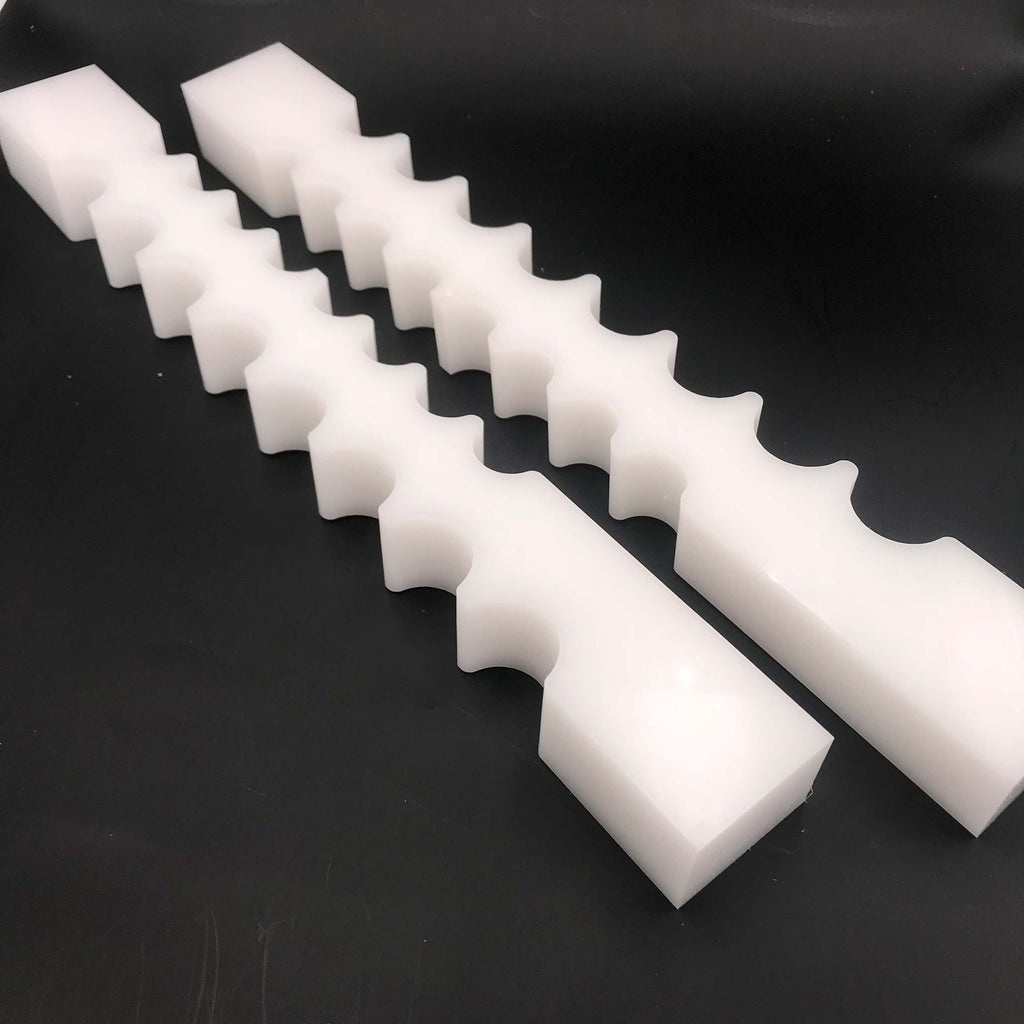

Optimizing CNC Machining Operations for HDPE Plastic - Tips and Techniques

Recommended Coolants and Lubricants for HDPE

HDPE's low coefficient of friction allows it to be machined dry, but using coolants and lubricants is recommended to regulate temperature and evacuate chips. Consider these HDPE-compatible options:

- Water-Soluble Oils: At 15-25% concentration, water-soluble oils effectively lubricate the cut while controlling heat buildup during machining.

- Synthetics: PEGs, esters, polyalkylene glycols and other synthetics are stable options for HDPE, provided proper filtration.

- Through Tool Delivery: For pressurized through-tool lubricant, use 500-1500 psi to adequately penetrate HDPE's pore-free structure.

Proper filtration, skimming, and concentration control prevents oils and fats from contaminating HDPE surfaces, avoiding defects.

Key Takeaways for Machining HDPE with CNC

With its stellar strength-to-weight characteristics and machinability, HDPE is here to stay as a staple plastic for engineered components. By adopting the tips above, you can optimize your CNC machining operations to make the most of this material’s potential.

- Select specialized tooling engineered for plastics

- Use conservative speeds and feeds to prevent melting and build-up

- Minimize part deformation through fixturing and stock allowance

- Dial in fine stepovers, climb moves, and lubrication for good finishes

- Choose compatible coolants and synthetics to regulate cutting temperature

With the right techniques, HDPE can be a breeze to machine accurately and efficiently on CNC mills and lathes. Optimizing your process for this high-demand material can lead to improved performance and part quality.