You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

UHMW-PE Machining

UHMW-PE (UHMWPE) Custom Machining & Stock Materials

Ultra-High Molecular Weight Polyethylene (UPE) Solutions with ±0.03mm CNC Precision

Leading UHMWPE supplier offering custom CNC machined UHMW parts, sheets, rods, and engineering solutions. From prototype to production, we deliver superior UHMW polyethylene components that outperform metal in wear applications.

Why Engineers Choose UHMW-PE (UHMWPE) Over Traditional Materials

Ultra-high molecular weight polyethylene (UPE) offers unmatched performance where metals and standard plastics fail. Discover why UHMW polyethylene is the material of choice for demanding applications.

🎯 Superior Performance Benefits

- ✓ Exceptional Wear Resistance: UHMWPE outlasts steel by 15x in abrasive environments

- ✓ Self-Lubricating: Ultra-low friction coefficient (0.07-0.15) eliminates need for oils

- ✓ Impact Absorption: UHMW-PE absorbs shock without cracking or breaking

- ✓ Chemical Inertness: Resists acids, alkalis, and most solvents

📊 UHMW-PE Technical Properties

| Property | Value | Advantage |

| Density | 0.93 g/cm³ | 7x lighter than steel |

| Molecular Weight | 3-9 million g/mol | Superior toughness |

| Water Absorption | <0.01% | Dimensional stability |

| Tensile Strength | ≥40 MPa | High load capacity |

| Shore Hardness | 63-67 Shore D | Optimal flexibility |

| Impact Strength | No break | Exceptional toughness |

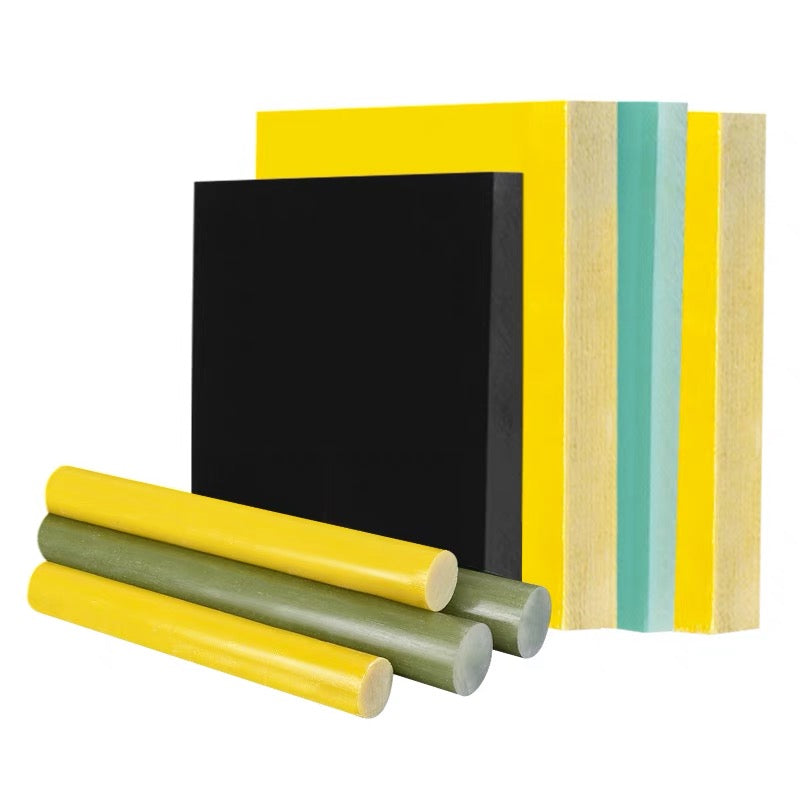

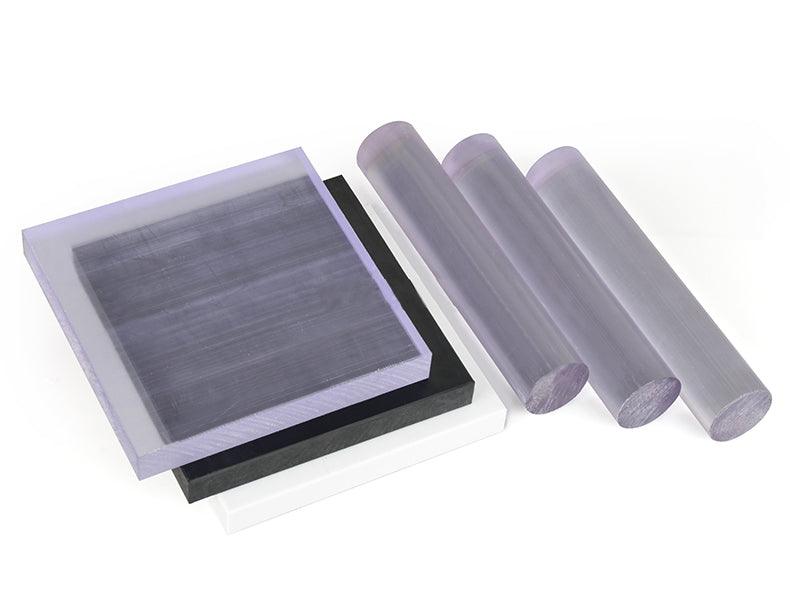

Complete UHMWPE Solutions: Custom Manufacturing & Stock Materials

UHMW-PE Applications Across Industries

From food processing to heavy machinery, UHMWPE delivers unmatched performance. See how industries rely on UHMW polyethylene for critical applications.

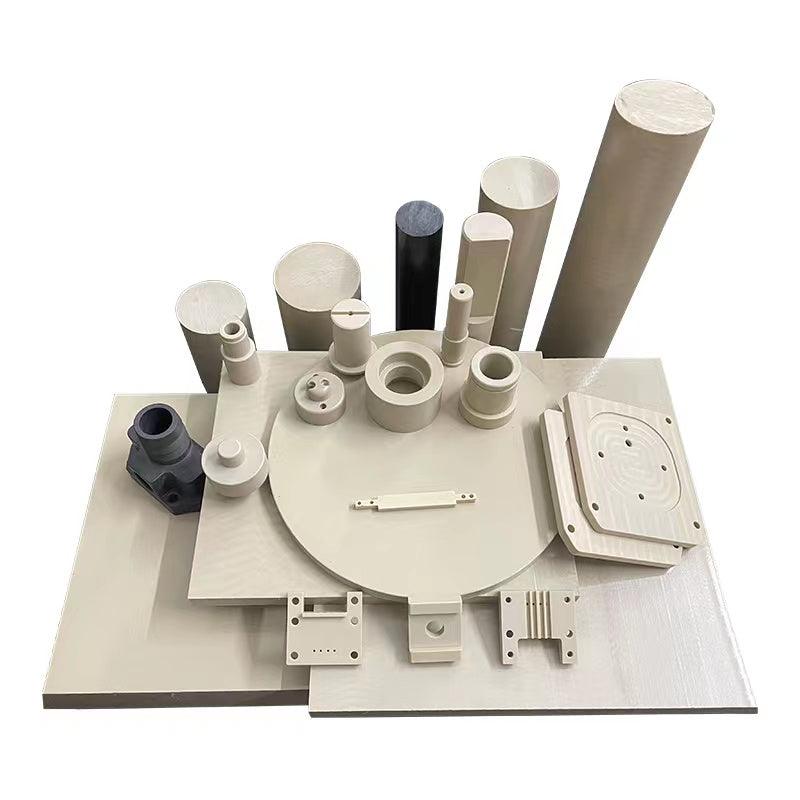

Advanced UHMW-PE Manufacturing Capabilities

State-of-the-art equipment and expertise to transform UHMWPE into precision components

Precision CNC Machining

Multi-axis CNC centers achieving ±0.03mm tolerances on complex UHMW polyethylene parts. From simple cuts to intricate 3D geometries.

Learn More →Custom Cut-to-Size

Save material costs with precise cutting of UHMWPE sheets and rods to your exact specifications. Minimize waste, maximize value.

Cut-to-Size Service →Laser Cutting & Engraving

Intricate patterns and detailed engravings on UHMW-PE with laser precision. Perfect for branding and complex cutouts.

Laser Services →Injection Molding

High-volume production of complex UHMWPE parts with consistent quality. Ideal for large production runs with tight specifications.

Molding Options →Heat Bending & Forming

Create complex curved shapes from UHMW sheets using controlled heat forming. No stress points, maintaining material properties.

Bending Services →Plastic Welding

Expert welding of UHMWPE components for large assemblies and tanks. Strong, leak-proof joints for demanding applications.

Welding Capabilities →Why Choose UHMW-PE Over Alternative Materials?

Bottom Line: UHMW-PE delivers the best combination of wear resistance, impact strength, and cost-effectiveness for demanding applications

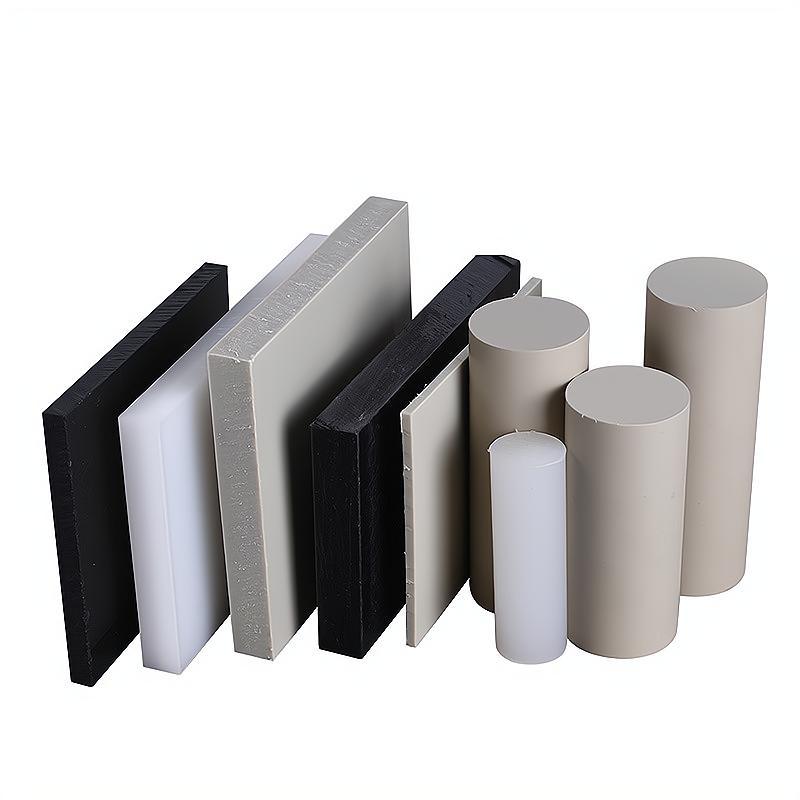

UHMW-PE Material Grades for Every Application

Standard UHMW-PE

General-purpose UHMWPE for most industrial applications. Excellent wear resistance and impact strength at an economical price point.

- ✓ Molecular weight: 3-6 million g/mol

- ✓ Operating temp: -150°C to 90°C

- ✓ Shore D hardness: 63-67

- ✓ Cost-effective solution

FDA-Compliant UHMW

Food-grade UHMWPE meeting FDA and EU food contact regulations. Ideal for direct food processing applications.

- ✓ FDA 21 CFR 177.1520 compliant

- ✓ EU 10/2011 approved

- ✓ Non-toxic, non-contaminating

- ✓ Easy to clean and sanitize

Anti-Static UHMWPE

ESD-safe UPE material for electronics and explosive environments. Prevents static buildup while maintaining UHMW properties.

- ✓ Surface resistivity: 10⁶-10⁹ Ω

- ✓ ESD protection certified

- ✓ Black color standard

- ✓ Maintains wear resistance

Reprocessed UHMW

Economical UHMW polyethylene for less demanding applications. Maintains good properties at reduced cost.

- ✓ 20-30% cost savings

- ✓ Good wear resistance

- ✓ Environmentally friendly

- ✓ Non-critical applications

Oil-Filled UHMWPE

Enhanced lubrication UHMW-PE with embedded oil for ultra-low friction in dry-running applications.

- ✓ Self-lubricating enhanced

- ✓ Coefficient of friction: 0.05-0.08

- ✓ Extended service life

- ✓ No external lubrication needed

UV-Stabilized UHMW

Weather-resistant UHMWPE for outdoor applications. UV inhibitors prevent degradation from sun exposure.

- ✓ UV-8 weather rating

- ✓ Outdoor durability 10+ years

- ✓ Color stability maintained

- ✓ Marine & construction use

Need Help Selecting the Right UHMW-PE Grade?

Our engineering team provides free material selection guidance and design optimization support for your UHMWPE projects

Design Review

Free DFM analysis and optimization suggestions

Material Selection

Expert guidance on optimal UHMW grade for your application

Cost Optimization

Strategies to reduce costs without compromising quality

Fast Prototyping

Quick-turn samples for testing and validation

UHMW-PE Frequently Asked Questions

What is the difference between UHMW-PE, UHMWPE, and UPE?

These are all names for the same material - Ultra-High Molecular Weight Polyethylene. UHMW-PE and UHMWPE are the most common abbreviations in North America, while UPE is often used in Asia and Europe. The material has a molecular weight between 3-9 million g/mol, making it significantly tougher than standard polyethylene (HDPE) which has a molecular weight around 500,000 g/mol.

Can UHMW polyethylene replace metal parts in my application?

Yes, UHMWPE successfully replaces metal in many applications, offering superior wear resistance, self-lubrication, and 1/7 the weight of steel. It's particularly effective in wear applications, conveyor systems, and food processing equipment. Our engineering team can analyze your specific application to determine if UHMW-PE is suitable and help optimize the design for plastic materials.

What tolerances can you achieve when machining UHMW plastic?

Our advanced CNC machining centers achieve tolerances of ±0.03mm (±0.0012") on UHMWPE parts. For less critical dimensions, we typically work to ±0.1mm to optimize cost. The achievable tolerance depends on part geometry, size, and specific features. We'll review your drawings and recommend appropriate tolerances for each dimension.

Is UHMW-PE FDA approved for food contact?

Yes, we offer FDA-compliant UHMW polyethylene grades that meet FDA 21 CFR 177.1520 and EU 10/2011 regulations for direct food contact. These grades are non-toxic, non-contaminating, and ideal for cutting boards, conveyor components, and food processing equipment. Please specify FDA compliance when requesting a quote.

What is your minimum order quantity for custom UHMWPE parts?

We have no minimum order quantity! Whether you need a single prototype or thousands of production parts, BeePlastic can accommodate your needs. This flexibility makes us ideal for R&D projects, replacement parts, and full-scale production runs. We offer competitive pricing at all quantities with volume discounts available.

How does UHMW-PE perform in extreme temperatures?

UHMWPE maintains excellent properties from -150°C to +90°C (-238°F to +194°F) for continuous service. It can handle short-term exposure up to 130°C. Unlike many plastics, UHMW polyethylene retains impact strength at extremely low temperatures, making it ideal for cryogenic applications. The material's low thermal expansion coefficient ensures dimensional stability across temperature ranges.

Can UHMW plastic be welded or bonded?

Yes, UHMW-PE can be welded using specialized plastic welding techniques including hot gas welding, extrusion welding, and friction stir welding. Due to its low surface energy, adhesive bonding requires surface treatment. Our welding specialists can create strong, leak-proof joints for tanks, liners, and large assemblies. Contact us to discuss your specific welding requirements.

Start Your UHMW-PE Project Today

Join thousands of engineers who trust BeePlastic for precision UHMWPE machining and quality UHMW stock materials

Fast response guaranteed

Tight tolerance CNC machining

From 1 piece to 10,000+

5-10 days typical turnaround

📧 Email: beeplastic@beeplastic.com

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog