You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

Plastic Bending

Why Choose Plastic Bending?

Discover the advantages of heat forming thermoplastics for your custom manufacturing projects

Our Advanced Bending Center

State-of-the-art equipment for precision plastic sheet forming and bending operations

Advanced Bending Technologies

Multiple forming methods to achieve perfect results for every application and material type

Precision Bending Showcase

Real projects demonstrating our plastic forming capabilities across different materials and applications

Compatible Thermoplastic Materials

Our bending center handles a wide range of thermoplastic sheet materials with optimized forming parameters

Need a different material? We also work with HDPE, POM, Nylon, PEEK, and other engineering plastics.

View All Plastic Materials →Industry Applications

Precision plastic bending serves diverse sectors from retail displays to industrial safety equipment

Retail & Point-of-Sale

- ✓ Acrylic display stands & product holders

- ✓ Brochure dispensers & literature holders

- ✓ LED-illuminated signage & menu boards

- ✓ Product glorifiers & jewelry displays

Industrial Safety Equipment

- ✓ Machine guards & operator shields

- ✓ Protective equipment enclosures

- ✓ Welding screens & safety barriers

- ✓ Transparent viewing windows for machinery

Lighting & Architecture

- ✓ LED light diffusers & lamp shades

- ✓ Ceiling fixtures & pendant housings

- ✓ Architectural decorative panels

- ✓ Custom skylights & light wells

Electronic Enclosures

- ✓ Control panel covers & housings

- ✓ Electrical equipment enclosures

- ✓ Instrument panel shields

- ✓ Touch screen protective housings

Medical & Laboratory

- ✓ Medical device housings & covers

- ✓ Laboratory safety shields

- ✓ Sterilizable instrument trays

- ✓ Diagnostic equipment enclosures

Automotive & Transportation

- ✓ Dashboard components & trim pieces

- ✓ Interior protective panels

- ✓ Lighting reflectors & housings

- ✓ Custom vehicle interior fittings

Technical Specifications

Detailed capabilities and tolerances for professional plastic bending operations

| Specification | Capability Range |

|---|---|

| Material Thickness Range | 1.5mm - 25mm (0.06" - 1.0") |

| Maximum Bending Length | Up to 3000mm (118") continuous line bends |

| Bend Angle Tolerance | ±1° to ±2° (length dependent) |

| CNC Precision | ±0.03mm (±0.0012") repeatable accuracy |

| Minimum Bend Radius | From 2mm (material thickness dependent) |

| Simultaneous Bends (CNC) | Up to 6 bends in one operation |

| Maximum Sheet Size | 2400mm × 1200mm (96" × 48") |

| Production Volume | No MOQ - From 1 prototype to 10,000+ units |

| Lead Time | 3-7 days (prototypes) | 7-15 days (production) |

| Quality Assurance | 100% dimensional inspection, visual quality checks |

Frequently Asked Questions

Common questions about our plastic bending and forming services

What is the minimum bend radius for plastic sheets?

The minimum bend radius depends on material type and thickness. As a general rule, the minimum inside bend radius should be 1.5-2× the material thickness for most thermoplastics. Acrylic, PC, and PETG can achieve tighter radii with proper heating techniques.

Can you maintain optical clarity when bending transparent plastics?

Yes! Our precision heating methods maintain 90-95% optical clarity in transparent materials like acrylic, polycarbonate, and PETG. We control heating temperature and cooling rates to prevent stress whitening, haziness, or distortion.

Is there a minimum order quantity requirement?

No, we have no minimum order quantity! Whether you need a single prototype for design validation or 10,000 production units, we can accommodate your needs with competitive pricing for both small and large volumes.

What file formats do you accept for custom bending projects?

We accept all standard CAD formats including .STEP, .STL, .IGES, .DWG, .DXF, and .PDF technical drawings. If you don't have CAD files, hand sketches with dimensions are acceptable – our team will convert them to production specifications.

How long does it take to receive bent plastic components?

Prototype lead time: 3-7 business days after design approval. Production runs: 7-15 business days depending on quantity. Rush services available for urgent projects. Shipping time varies by location.

Complete Plastic Fabrication Solutions

Maximize efficiency by combining plastic bending with our full range of manufacturing services

CNC Plastic Machining →

Precision milling, turning, and drilling with ±0.03mm tolerance.

Laser Cutting & Engraving →

Clean, precise cuts and intricate engravings before bending.

Plastic Welding & Bonding →

Join multiple bent sections for complex assemblies.

Injection Molding →

Transition from prototypes to high-volume production.

Cut-to-Size Services →

Precision-cut sheets and rods ready for bending.

Case Studies →

See how we've solved complex fabrication challenges.

BeePlastic has been providing precision plastic bending and forming services for over 15 years, serving industries including aerospace, automotive, medical devices, retail displays, industrial equipment, and electronics manufacturing worldwide. Our commitment to quality, competitive pricing, and exceptional customer service makes us your trusted partner for custom thermoplastic components.

Learn More

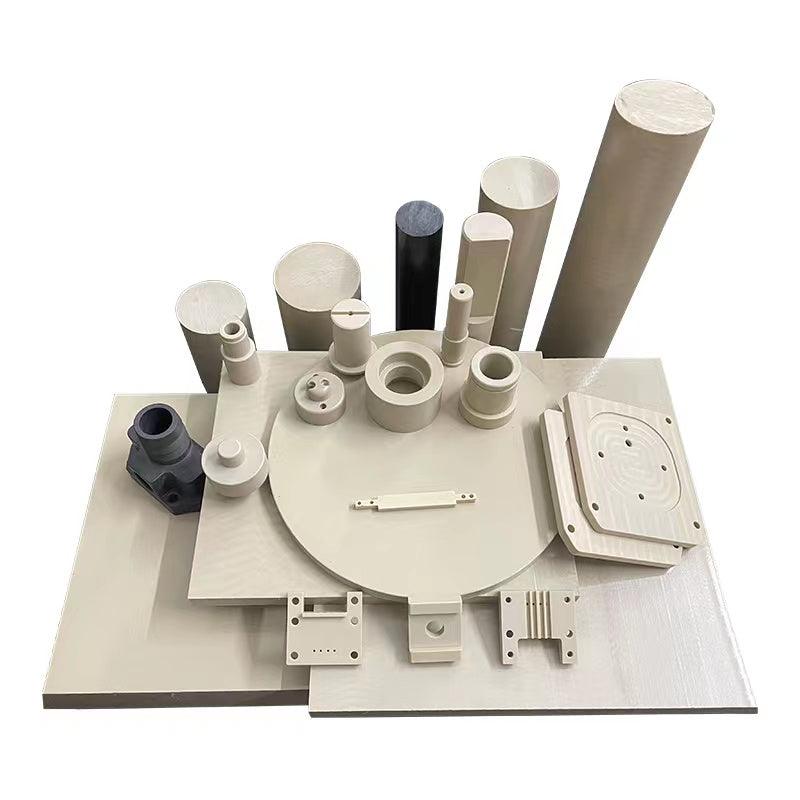

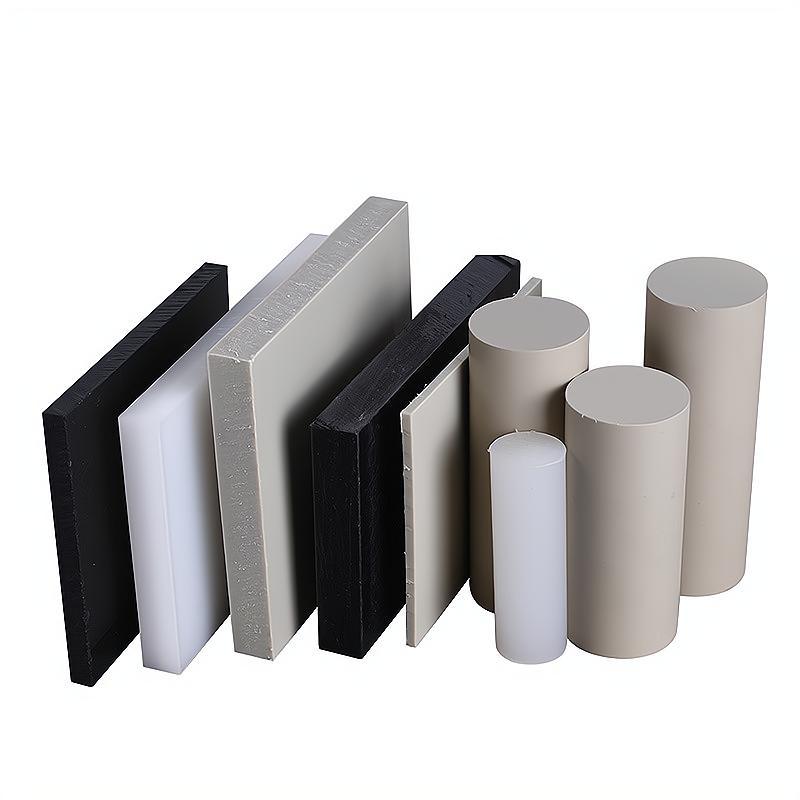

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

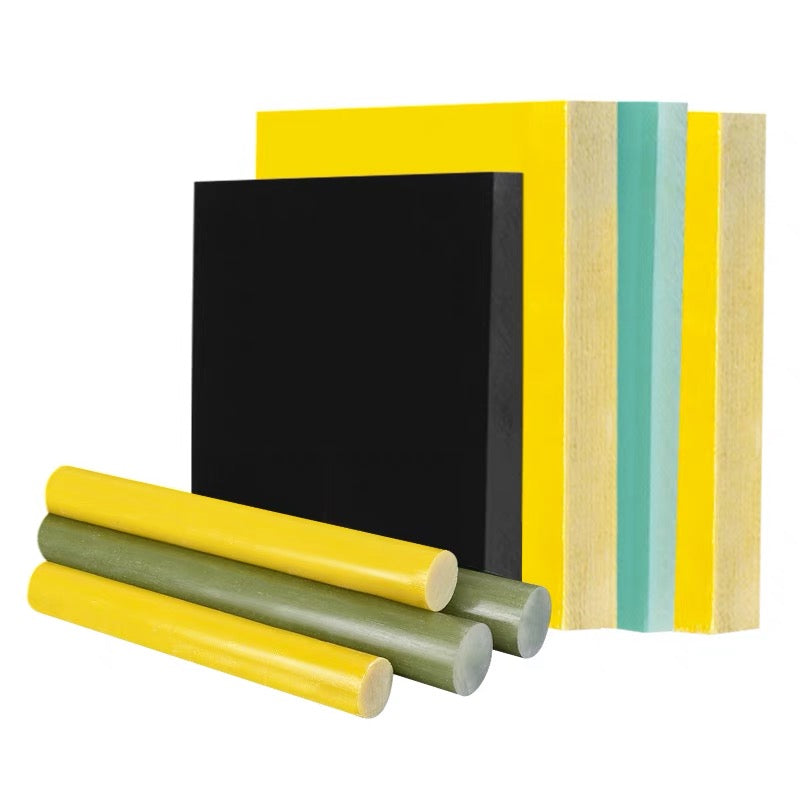

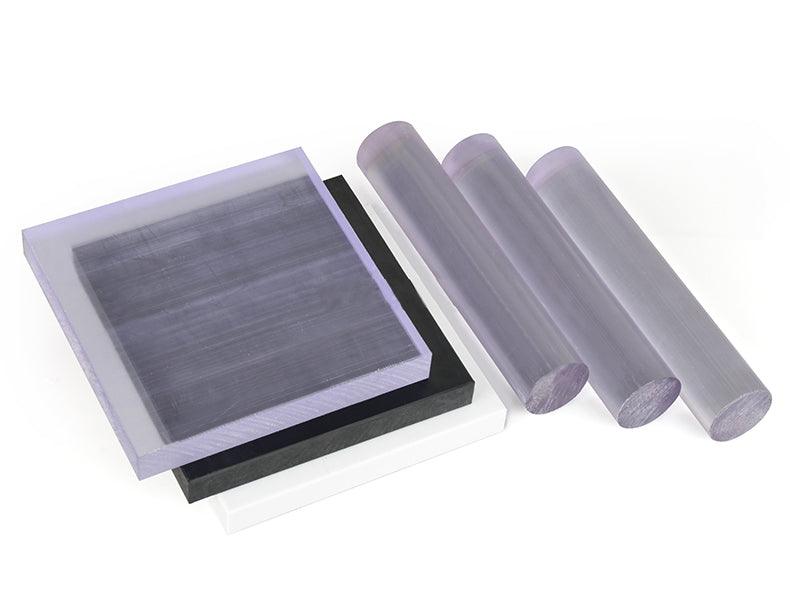

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog