You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

PEI Machining

PEI (Ultem®) Plastic Sheets, Rods & Custom Machined Parts

High-performance polyetherimide engineering plastic for aerospace, medical, electronics, and automotive applications. Superior heat resistance up to 170°C continuous use with exceptional mechanical strength and chemical resistance.

What is PEI (Polyetherimide) Plastic?

Understanding the superior properties and applications of Ultem® PEI engineering thermoplastic

PEI (Polyetherimide), commercially known as Ultem®, is an amorphous, amber-colored high-performance thermoplastic that offers an exceptional combination of thermal stability, mechanical strength, and chemical resistance. This advanced engineering polymer maintains its properties at continuous service temperatures up to 170°C (338°F), making it ideal for demanding applications where conventional plastics fail.

With a glass transition temperature of 217°C, PEI plastic provides outstanding dimensional stability even under extreme conditions. The material achieves UL94 V-0 flame rating without additives, producing minimal smoke and toxic gas emissions - critical for aerospace and transportation safety requirements.

Key Properties of PEI Ultem Material

PEI polyetherimide combines multiple performance advantages that make it superior to standard engineering plastics. The material offers tensile strength of 110-150 MPa, excellent electrical insulation with volume resistivity >10¹⁶ Ω·cm, and minimal water absorption of less than 0.25%. This unique property profile makes PEI suitable for precision components in medical devices, semiconductor equipment, and aerospace applications.

Unlike many high-temperature plastics, PEI material is transparent to microwave radiation and offers excellent hydrolytic stability, allowing it to withstand repeated steam sterilization cycles. The material's inherent chemical resistance to automotive fluids, cleaning agents, and aqueous solutions ensures long service life in harsh environments.

Why Choose PEI?

- Continuous use temperature to 170°C

- Glass transition at 217°C

- UL94 V-0 flame retardant

- FAR 25.853 compliant

- FDA & USP Class VI approved

- Steam sterilizable (autoclave)

- Low smoke & toxicity

- Excellent electrical insulation

- Chemical resistance

- Dimensional stability

PEI Material Properties & Performance

Comprehensive technical characteristics that make polyetherimide the preferred choice for critical applications

Thermal Stability

PEI plastic maintains mechanical properties at continuous temperatures up to 170°C with short-term resistance to 200°C. Glass transition at 217°C ensures dimensional stability.

170°C ContinuousMechanical Strength

Superior tensile strength of 110-150 MPa combined with flexural modulus of 3500 MPa. High impact resistance and excellent creep resistance under load.

110 MPa TensileChemical Resistance

Resistant to automotive fluids, fully halogenated hydrocarbons, alcohols, and weak acids. Excellent hydrolytic stability for steam sterilization.

Broad CompatibilityElectrical Properties

Outstanding electrical insulation with volume resistivity >10¹⁶ Ω·cm and dielectric strength of 27 kV/mm. Stable properties over wide temperature range.

27 kV/mm DielectricFlame Retardancy

Inherent UL94 V-0 rating without additives. Low smoke generation and toxicity meet FAR 25.853 requirements. Oxygen index (LOI) of 47%.

UL94 V-0 RatedLow Moisture Absorption

Water absorption less than 0.25% at 23°C ensures excellent dimensional stability and consistent electrical properties in humid environments.

<0.25% AbsorptionPEI Technical Data Sheet & Specifications

Detailed material properties for engineering evaluation and design verification

Mechanical Properties

| Tensile Strength at Yield | 110 MPa |

| Tensile Modulus | 3500 MPa |

| Flexural Strength | 165 MPa |

| Flexural Modulus | 3510 MPa |

| Impact Strength (Notched) | 53 J/m |

| Elongation at Break | 60% |

| Hardness (Rockwell M) | 109 |

| Density | 1.27 g/cm³ |

Thermal & Electrical Properties

| Continuous Service Temperature | 170°C |

| Glass Transition Temperature | 217°C |

| Heat Deflection Temp (1.82 MPa) | 201°C |

| Thermal Conductivity | 0.22 W/m·K |

| Coefficient of Thermal Expansion | 5.6×10⁻⁵ /°C |

| Water Absorption (24 hrs) | 0.25% |

| Volume Resistivity | >10¹⁶ Ω·cm |

| Dielectric Strength | 27 kV/mm |

PEI Ultem Applications by Industry

Proven performance in mission-critical components across diverse industrial sectors

Aerospace & Aviation

- Aircraft interior components (FAR 25.853)

- Electrical connectors and wire insulation

- Air and fluid ducting systems

- Seat components and structural brackets

- Radomes and antenna housings

- Cabin pressure valves and fittings

Medical & Healthcare

- Reusable surgical instrument handles

- Sterilizable medical device housings

- Dental instrument components

- Analytical laboratory equipment

- Pharmaceutical processing parts

- Fluid handling manifolds

Electronics & Semiconductor

- IC test sockets and burn-in fixtures

- Wafer handling and processing tools

- High-frequency circuit board substrates

- Electrical insulators and connectors

- LED reflectors and heat sinks

- 5G antenna and RF components

Automotive & EV

- Under-hood temperature sensors

- Transmission and powertrain parts

- Headlight reflectors and bezels

- EV battery insulators and separators

- Fuel system components

- Engine timing chain tensioners

Industrial Manufacturing

- High-temperature pump impellers

- Chemical-resistant valve seats

- Bearing cages and retainers

- Conveyor system components

- Oil & gas downhole tools

- Compressor valve plates

Food & Beverage

- FDA-compliant food contact parts

- Microwave-transparent components

- Commercial cooking equipment

- Food processing machinery parts

- Beverage dispensing components

- Reusable food service items

PEI Ultem Stock Shapes & Custom Components

Comprehensive inventory of polyetherimide sheets, rods, tubes, and precision-machined parts

In Stock

In Stock

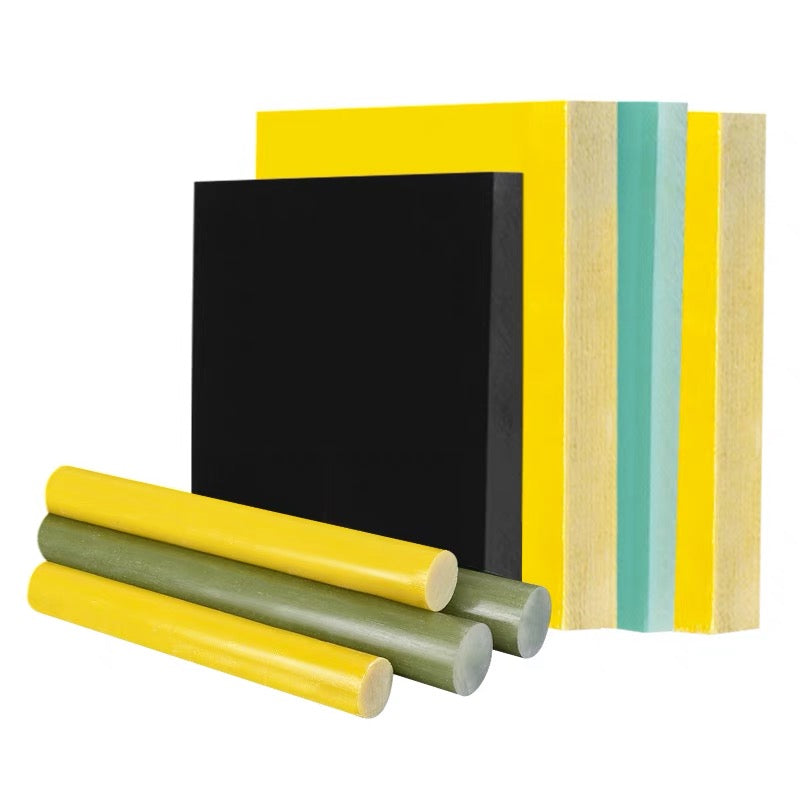

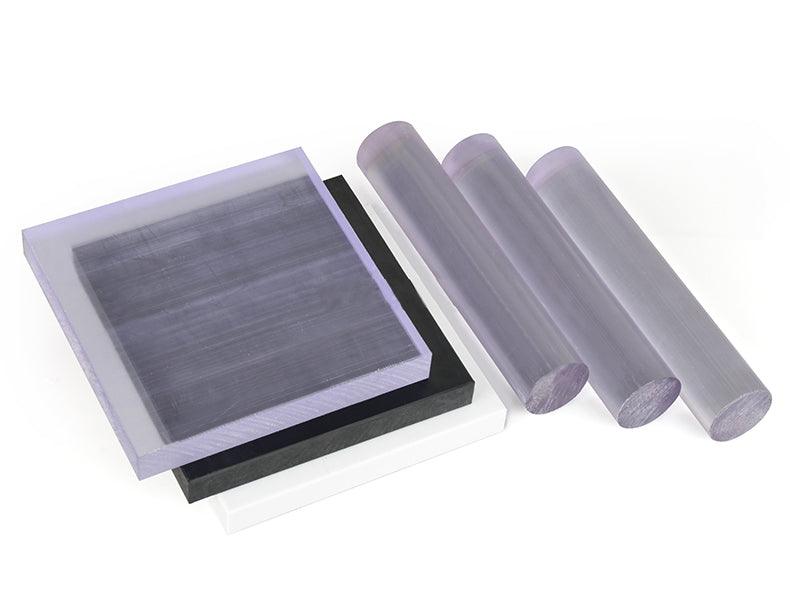

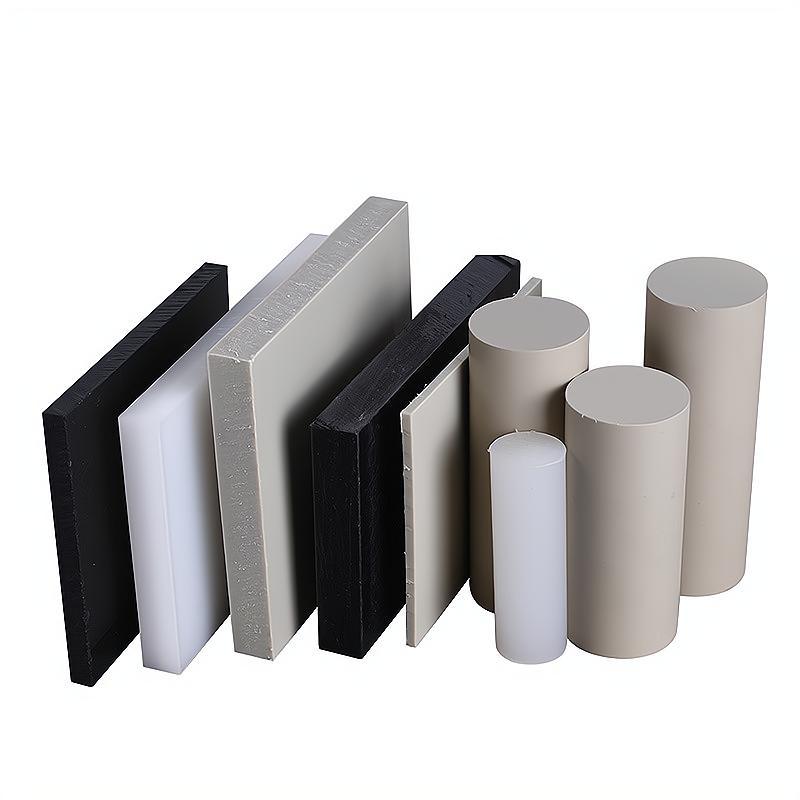

PEI Ultem Sheets

Premium polyetherimide sheet stock for CNC routing, laser cutting, and thermoforming. Available in natural amber and black colors.

- Thickness: 6mm to 100mm

- Size: 610mm × 1220mm standard

- Custom cut-to-size available

- RoHS & REACH compliant

Quick Ship

Quick Ship

PEI Ultem Rods

Extruded polyetherimide rod stock ideal for CNC turning, milling, and precision machining of bushings and insulators.

- Diameter: 6mm to 200mm

- Length: up to 1000mm

- Tight diameter tolerances

- Stress-relieved for stability

Custom Made

Custom Made

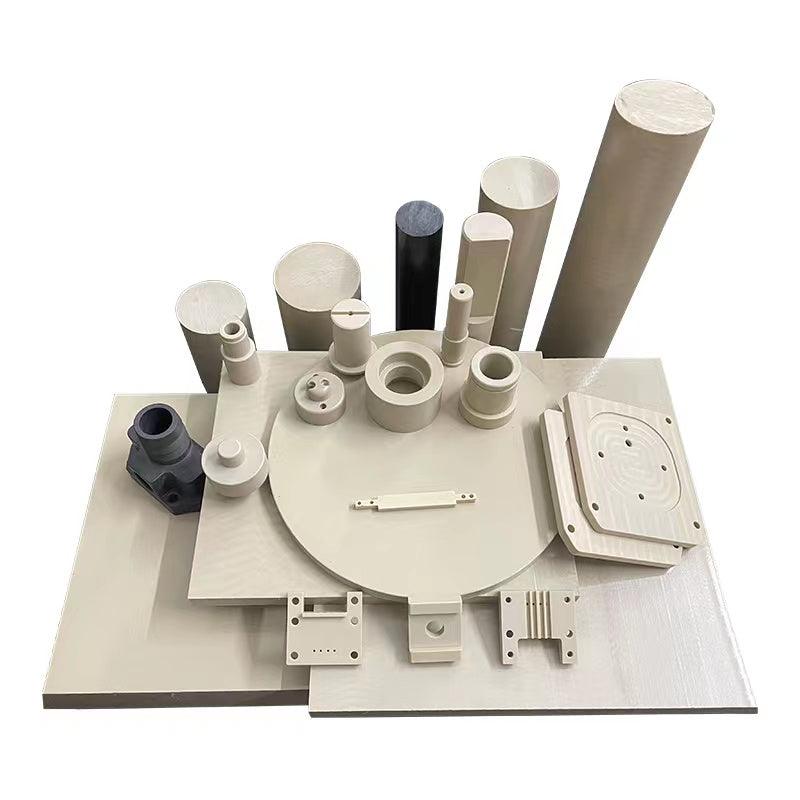

Custom PEI Machined Parts

Precision CNC machined Ultem components to your exact specifications. From prototypes to production runs.

- Tolerances to ±0.005"

- 5-axis CNC capability

- 1 to 10,000+ pieces

- Engineering support included

PEI Processing & Fabrication Services

Complete manufacturing capabilities for all your polyetherimide plastic needs

CNC Machining

5-axis CNC milling and turning for complex PEI parts with tight tolerances

Learn More →Complete Guide to PEI (Polyetherimide) Engineering Plastic

Understanding PEI Ultem Material Grades

Ultem 1000 is the standard unfilled grade of PEI plastic, offering the best balance of properties for general-purpose applications. This natural polyetherimide provides maximum electrical insulation properties, transparency to microwave radiation, and excellent surface finish when machined. The material's amber color is characteristic of pure PEI resin without additives.

For applications requiring enhanced stiffness and dimensional stability, glass-filled PEI grades like Ultem 2300 (30% glass fiber) increase flexural modulus by 40% while maintaining excellent thermal properties. Carbon fiber-reinforced PEI offers superior wear resistance and thermal conductivity for bearing applications and heat dissipation components.

PEI Material Selection Guide

• Ultem 1000: Best for electrical insulation, food contact, medical devices

• Ultem 2300 (30% GF): Structural components requiring higher stiffness

• Carbon-filled PEI: Wear applications, thermal management

• Black PEI: UV resistance for outdoor exposure

PEI vs PEEK: Making the Right Material Choice

When comparing PEI vs PEEK for high-temperature applications, PEI often provides the best value for applications below 170°C. While PEEK offers higher temperature resistance (250°C continuous), PEI polyetherimide costs 40-60% less and provides adequate performance for most applications. PEI's superior electrical properties and transparency to microwave radiation make it preferable for electronic and microwave applications.

The key advantages of PEI over PEEK include lower cost, better electrical insulation, inherent flame resistance without additives, and easier machinability. PEEK excels in extreme chemical environments and temperatures above 170°C, but for most aerospace, medical, and electronic applications, PEI Ultem provides the optimal balance of performance and cost.

CNC Machining PEI: Best Practices and Guidelines

Successfully machining PEI plastic requires understanding its unique characteristics. The material's high glass transition temperature (217°C) allows aggressive cutting parameters without melting. Use sharp carbide tools with positive rake angles for optimal chip evacuation. Recommended cutting speeds range from 500-1000 SFM for milling operations.

When drilling PEI sheets or rods, use standard HSS or carbide drills with 118-135° point angles. Pecking cycles prevent heat buildup and ensure clean holes. For threading, single-point thread milling produces superior results compared to tapping, especially for fine pitches. Coolants improve surface finish and extend tool life, though many machinists successfully cut PEI dry with compressed air chip evacuation.

PEI Processing Techniques and Considerations

Thermoforming PEI sheets requires heating to 180-200°C, just below the glass transition temperature. Pre-drying at 150°C for 2-4 hours removes moisture that could cause surface defects. Vacuum forming and pressure forming both work well, with male molds providing better dimensional control for deep draws.

For injection molding PEI, melt temperatures of 350-400°C and mold temperatures of 135-165°C produce optimal results. The material's low shrinkage (0.5-0.7%) ensures excellent dimensional accuracy. Proper venting prevents burn marks, while generous radii prevent stress concentrations.

Derations for PEI Components

When designing with PEI plastic, consider the material's anisotropic properties and low shrinkage rates. Wall thickness variations should be minimized to prevent warpage. For CNC machined PEI parts, design with generous radii (minimum 0.5mm) to prevent stress concentrations. Threaded features should have minimum 2× diameter engagement length for optimal strength.

PEI's excellent creep resistance makes it ideal for snap-fit assemblies and living hinges. Design snap-fits with 1-2% strain maximum to prevent failure. For high-temperature applications, account for thermal expansion (56 ppm/°C) when designing tight-tolerance assemblies.

Why Choose BeePlastic for PEI Solutions?

With over 20 years specializing in high-performance plastics, BeePlastic has developed extensive expertise in PEI processing. Our state-of-the-art CNC machining centers, combined with experienced engineers, ensure your PEI components meet the most demanding specifications. We maintain substantial inventory of PEI sheets, PEI rods, and PEI tubes for rapid turnaround.

Our capabilities span from prototype development through high-volume production. Whether you need PEI plastic cut to size, complex 5-axis machined components, or technical guidance on material selection, BeePlastic delivers comprehensive solutions. Our commitment to quality, competitive pricing, and responsive customer service makes us your ideal partner for all PEI polyetherimide plastic needs.

Ready to Start Your PEI Ultem Project?

Get expert guidance, competitive pricing, and fast delivery on all PEI plastic materials and custom components

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog