You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

PAI Machining

PAI (Polyamide-Imide) Material Solutions & Precision Machining Services

Industry-leading supplier of high-performance PAI plastic materials and custom polyamide-imide components. Serving aerospace, automotive, semiconductor & industrial sectors with ±0.03mm precision CNC machining.

⚡ 3-Day Rapid Prototyping • 🎯 ±0.03mm Precision • 🌍 Global Shipping • 📧 beeplastic@beeplastic.com

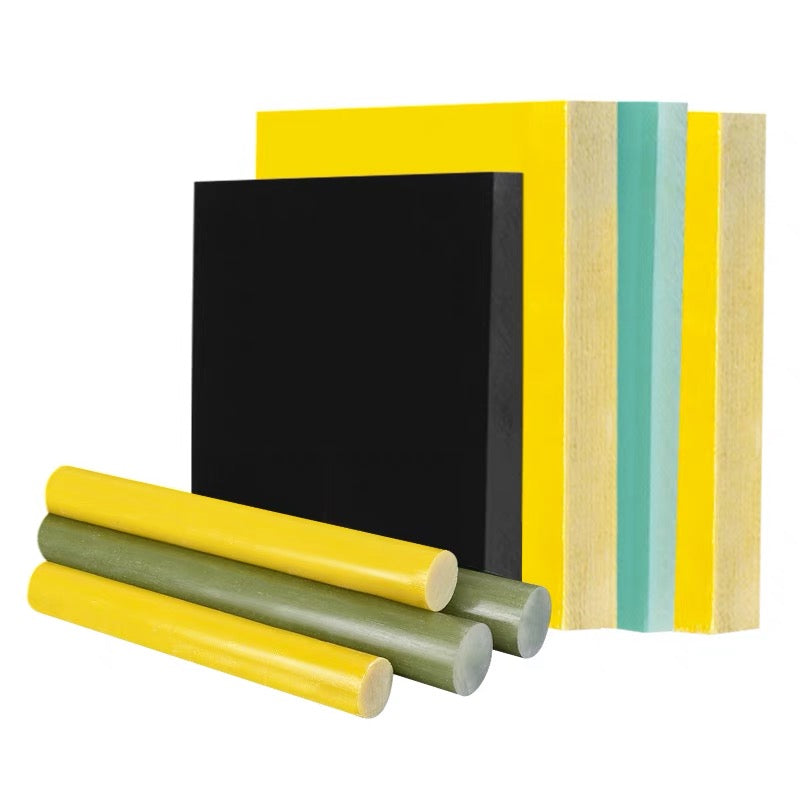

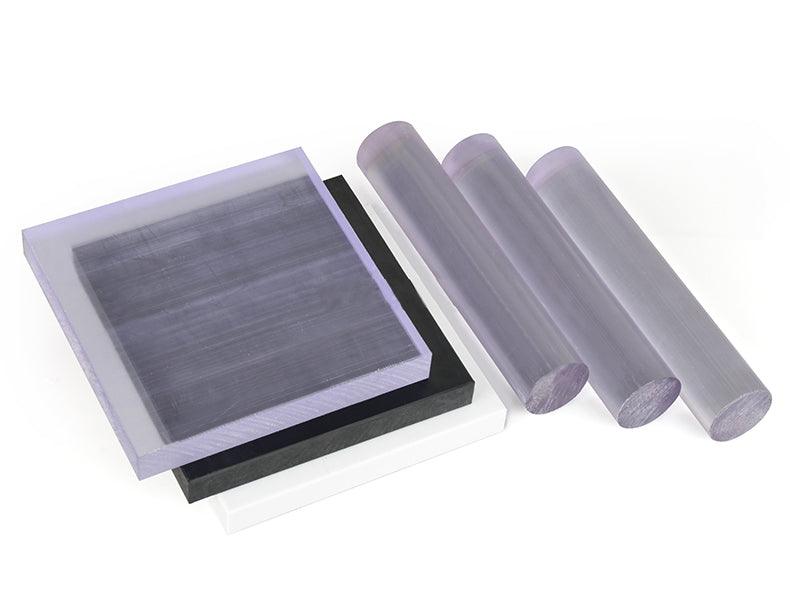

Premium PAI (Polyamide-Imide) materials and precision machining capabilities

Complete PAI Plastic Solutions for Your Engineering Challenges

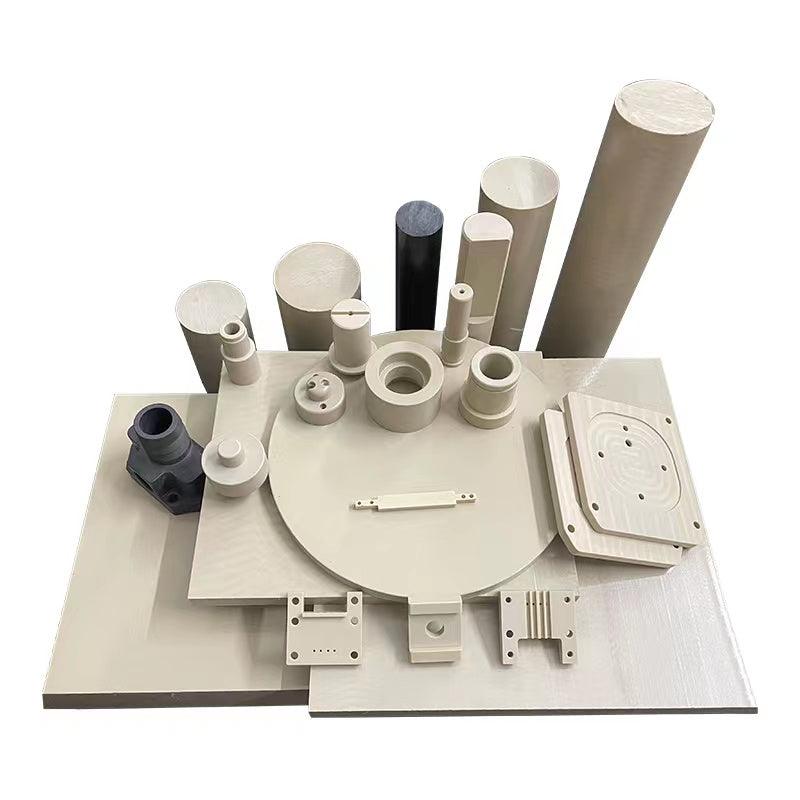

🔧 Custom PAI Machining & Fabrication

Transform PAI round rod (3-100mm diameter, 300mm/1200mm lengths) and sheet stock (300mm×300mm) into precision-engineered components using advanced CNC machining, laser cutting, and specialized fabrication techniques.

- CNC precision machining: ±0.03mm (±0.0012")

- 5-axis milling for complex PAI parts

- High-speed PAI turning up to 100mm diameter

- Wire EDM for intricate polyamide-imide geometries

- Surface grinding to Ra 0.4μm finish

📦 PAI Material Stock & Supply

Comprehensive inventory of PAI rods, sheets, tubes, and plates ready for immediate shipment. All polyamide-imide materials meet ASTM specifications.

- PAI round rods: 3mm to 100mm diameter

- PAI sheets: 300mm×300mm standard plates

- PAI rod lengths: 300mm or 1200mm long

- Natural (tan/amber) and black colors

- Same-day cut-to-size service available

PAI delivers superior strength-to-weight ratio vs PEEK, PEI, and other high-performance plastics

Why Engineers Choose PAI (Polyamide-Imide) Plastic

PAI polymer offers the highest strength and stiffness of any thermoplastic up to 275°C, making polyamide-imide the ideal metal replacement for extreme applications

260°C

Continuous Service Temperature

110 MPa

Tensile Strength

0.25

Coefficient of Friction

80%

Weight Reduction vs Steel

🎯 Critical PAI Material Advantages

Polyamide-imide maintains over 85% of room temperature strength at 200°C, outperforming PEEK, PEI, PPS, and PPA in high-temperature applications. PAI plastic's unique combination of thermal stability, mechanical strength, and self-lubricating properties makes it the preferred choice for aerospace bearings, automotive transmission components, and semiconductor test sockets.

Advanced 5-axis CNC machining ensures exceptional precision for critical PAI plastic parts

PAI Polyamide-Imide Applications by Industry

✈️ Aerospace PAI Components

High-performance polyamide-imide parts for extreme aerospace environments:

- PAI jet engine bearings & bushings

- Polyamide-imide thermal insulators

- PAI valve seats & seal rings

- High-temp PAI spacers & washers

- PAI aircraft interior components

🚗 Automotive PAI Parts

Durable PAI plastic solutions for drivetrain and powertrain systems:

- PAI transmission thrust washers

- Polyamide-imide shift fork pads

- PAI synchronizer rings

- High-temp PAI oil pump gears

- PAI turbocharger components

⚡ Semiconductor PAI Solutions

Precision PAI test fixtures and handling components:

- PAI IC test sockets & contactors

- Polyamide-imide wafer carriers

- PAI burn-in test fixtures

- ESD-safe PAI probe cards

- PAI pick-and-place nozzles

PAI thrust washers - 5x longer service life than bronze alternatives

Precision PAI test sockets maintain accuracy at 260°C continuous operation

PAI Material Technical Properties & Specifications

Comprehensive polyamide-imide performance data for engineering validation and material selection

| PAI Property | Test Method | Value | Units |

|---|---|---|---|

| Density | ASTM D792 | 1.43 | g/cm³ |

| Continuous Service Temperature | UL 746B | 260 | °C (500°F) |

| Glass Transition Temperature | ASTM E1545 | 280 | °C (536°F) |

| Heat Deflection Temperature | ASTM D648 | 310 | °C @ 1.8 MPa |

| Tensile Strength | ASTM D638 | 110 | MPa (16,000 psi) |

| Flexural Strength | ASTM D790 | 190 | MPa (27,500 psi) |

| Compressive Strength | ASTM D695 | 190 | MPa (27,500 psi) |

| Tensile Modulus | ASTM D638 | 4,200 | MPa (610 ksi) |

| Elongation at Break | ASTM D638 | 20 | % |

| Rockwell Hardness | ASTM D785 | E80 (M120) | - |

| Coefficient of Friction | ASTM D3702 | 0.25 | - |

| Thermal Expansion | ASTM E831 | 1.1 × 10⁻⁵ | cm/cm/°C |

| Water Absorption (24h) | ASTM D570 | 0.35 | % |

| Dielectric Strength | ASTM D149 | 250 | kV/mm |

| Flammability Rating | UL 94 | V-0 | - |

📊 Engineering Note: PAI polyamide-imide maintains superior dimensional stability with only 1.7% water absorption at saturation. This makes PAI plastic ideal for precision components in humid environments where PEEK and other materials may experience dimensional changes.

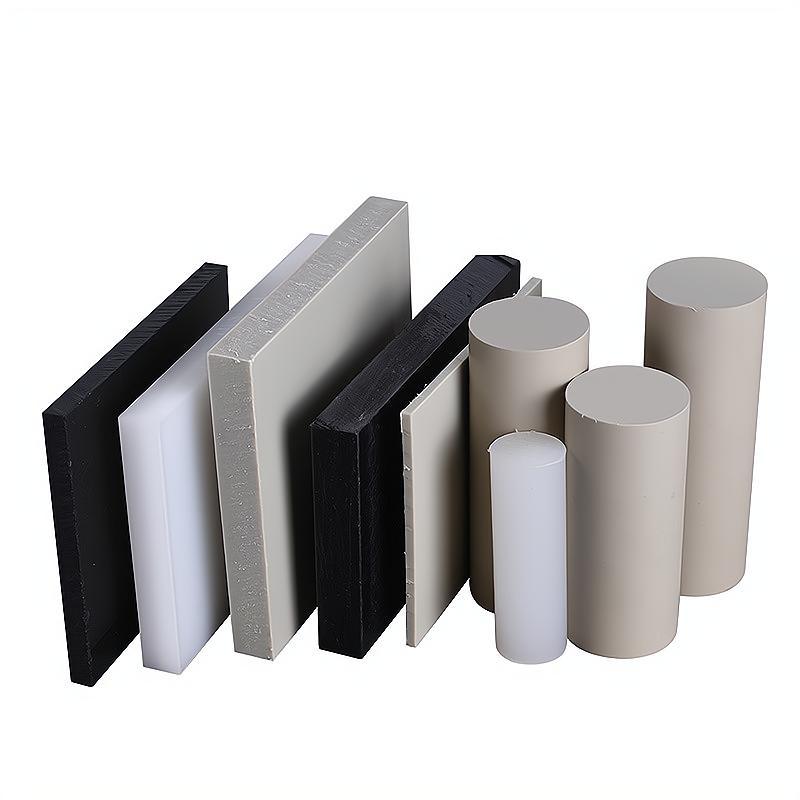

PAI Rod, Sheet & Tube Stock - Ready for Immediate Delivery

Comprehensive inventory of polyamide-imide materials in standard and custom sizes

Premium PAI rod, sheet, and tube stock - Available for same-day shipping

🔵 PAI Round Rod Stock

Diameter Range: 3mm - 100mm

Standard Lengths: 300mm, 1200mm long

Colors: Natural (amber/tan), Black

Grades: Unfilled, Glass-filled, Bearing grade

Form: Solid round bars

📐 PAI Sheet Stock

Standard Size: 300mm×300mm plates

Thickness Range: 6mm - 100mm

Custom Cutting: To your specifications

Surface: Smooth machined finish

Colors: Natural (amber/tan), Black

⭕ PAI Tube Stock

OD Range: 25mm - 200mm

Wall Thickness: 5mm - 25mm

Standard Length: 1200mm long

Custom Lengths: Available on request

Tolerances: ±0.1mm standard

Complete PAI Plastic Fabrication & Processing Services

Full-service polyamide-imide machining and fabrication capabilities under one roof

Why Engineers Choose BeePlastic for PAI Solutions

15+

Years PAI Experience

10,000+

PAI Parts Delivered

98.5%

On-Time Delivery

24hr

Quote Response

🎯 Our PAI Machining Precision Guarantee

Every polyamide-imide component we produce maintains ±0.03mm (±0.0012") dimensional tolerance, verified through comprehensive CMM inspection. We provide full documentation including material certifications, dimensional reports, and first article inspection for critical PAI parts.

Frequently Asked Questions About PAI Polyamide-Imide

Ready to Solve Your High-Performance Engineering Challenges?

Join thousands of engineers who trust BeePlastic for premium PAI polyamide-imide solutions

📧 Email: beeplastic@beeplastic.com

⚡ Response within 24 hours • 🚚 Global shipping available

Explore Our Other High-Performance Plastic Services

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog