You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

Custom POM Plastic Machining

Why Choose Beeplastic for POM/Acetal/Delrin® Solutions?

Precision CNC Machining

Advanced 3, 4, and 5-axis CNC milling and turning with ±0.03mm (±0.0012") tolerance. Perfect for tight-tolerance Delrin® gears, Acetal bushings, and POM precision components.

Rapid Prototyping

Fast turnaround from CAD to finished Polyoxymethylene parts. 2-3 days for simple Acetal prototypes, 5-7 days for complex POM assemblies.

Stock Materials Ready

Extensive inventory of POM-C (copolymer) and POM-H (homopolymer) sheets, rods, and tubes. Natural, black, white colors. Same-day cutting available.

Full-Service Manufacturing

Complete Acetal fabrication: CNC machining, injection molding, laser cutting, welding, and custom assembly. One-stop shop for all Delrin® needs.

Competitive Pricing

Direct manufacturer pricing for POM plastic parts. No middleman markup. Volume discounts available for production runs.

Global Shipping

Worldwide delivery of custom Polyacetal components and raw materials. Express shipping available for urgent projects.

Understanding POM/Acetal/Delrin® Engineering Plastic

Polyoxymethylene (POM), commonly known as Acetal or by DuPont's brand name Delrin®, is a high-performance engineering thermoplastic that excels in applications requiring superior mechanical properties, dimensional stability, and chemical resistance. This semi-crystalline polymer is the go-to material for precision components across automotive, medical, electronics, and industrial machinery sectors.

Key Properties of POM Plastic:

- High stiffness & strength (Tensile: 65-67 MPa)

- Excellent dimensional stability (low creep)

- Low coefficient of friction (0.2-0.3)

- Outstanding wear & abrasion resistance

- Low moisture absorption (<0.8%)

- Operating temperature: -40°C to +100°C

- Excellent machinability (best among plastics)

- Chemical resistance to fuels, oils, solvents

POM vs Other Names:

- POM - Chemical name (Polyoxymethylene)

- Acetal - Generic industry term

- Delrin® - DuPont's brand (POM-H)

- Polyacetal - Alternative chemical name

- POM-C - Copolymer version

- POM-H - Homopolymer version

- Tecaform - Ensinger brand

- Sustarin - Röchling brand

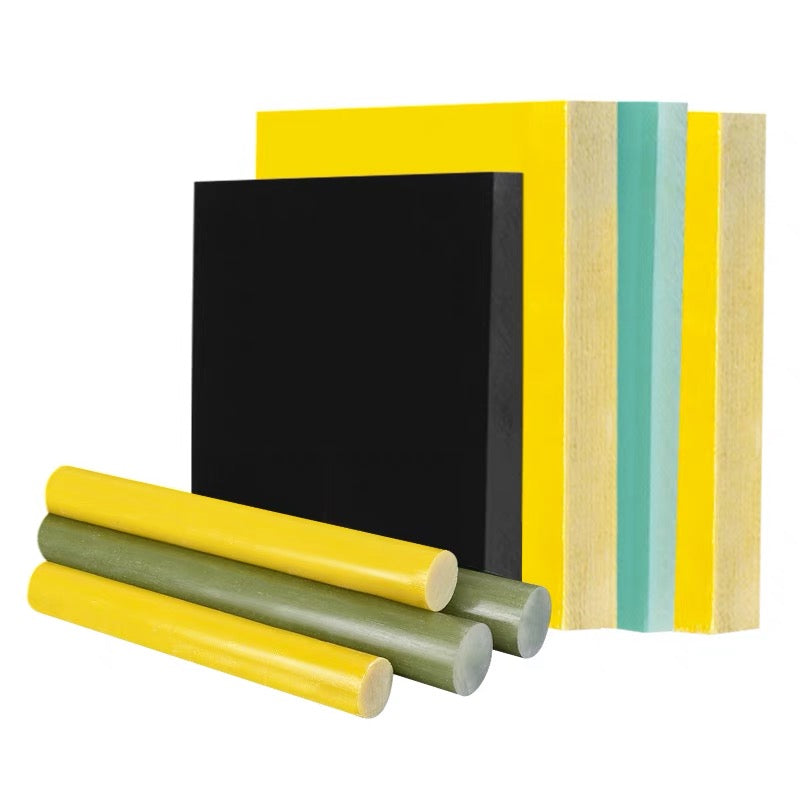

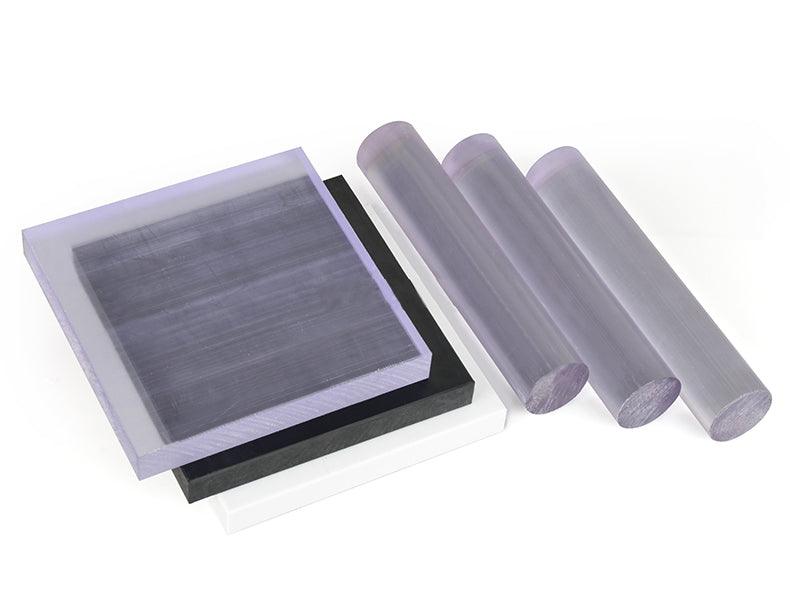

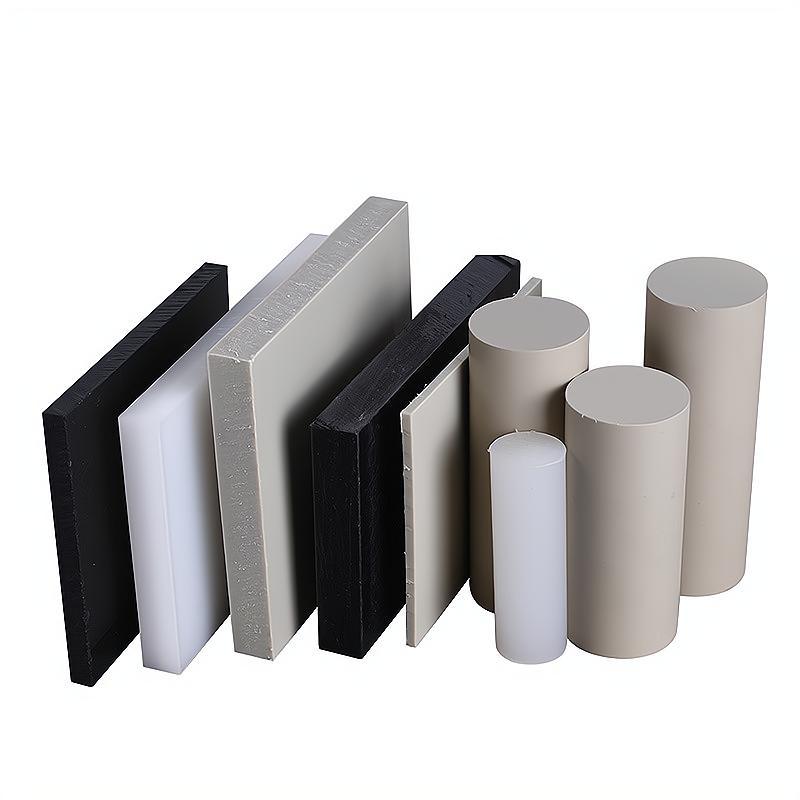

POM/Acetal Stock Shapes - Ready to Ship

POM/Acetal Sheets

- Thickness range: 6mm to 100mm (1/4" to 4")

- Standard sizes: 610x1220mm, 1000x2000mm

- Colors: Natural, White, Black, Blue

- Both POM-C and POM-H grades available

- Custom cut-to-size service available

- Multiple color options in stock

POM/Delrin® Rods

- Diameter range: 6mm to 300mm (1/4" to 12")

- Standard lengths: 1000mm, 2000mm, 3000mm

- Colors: Natural, White, Black, Blue

- Centerless ground options available

- Extruded and compression molded grades

- High-quality surface finish available

POM/Acetal Technical Specifications

| Property | POM-C (Copolymer/Acetal) | POM-H (Homopolymer/Delrin®) | Test Standard |

|---|---|---|---|

| Density | 1.39-1.41 g/cm³ | 1.42-1.43 g/cm³ | ISO 1183 |

| Tensile Strength | 65-67 MPa | 68-72 MPa | ISO 527 |

| Elongation at Break | 20-75% | 15-35% | ISO 527 |

| Flexural Modulus | 2,600-2,800 MPa | 2,900-3,100 MPa | ISO 178 |

| Impact Strength (Notched) | 6-8 kJ/m² | 7-10 kJ/m² | ISO 179 |

| Hardness (Rockwell) | M78-85 | M80-88 | ISO 2039 |

| Max Service Temperature | 100°C (212°F) | 110°C (230°F) | UL746B |

| Water Absorption (24h) | 0.20-0.25% | 0.20-0.25% | ISO 62 |

| Coefficient of Friction | 0.20-0.25 | 0.20-0.25 | ASTM D1894 |

| Dielectric Strength | 20-40 kV/mm | 20-40 kV/mm | IEC 60243 |

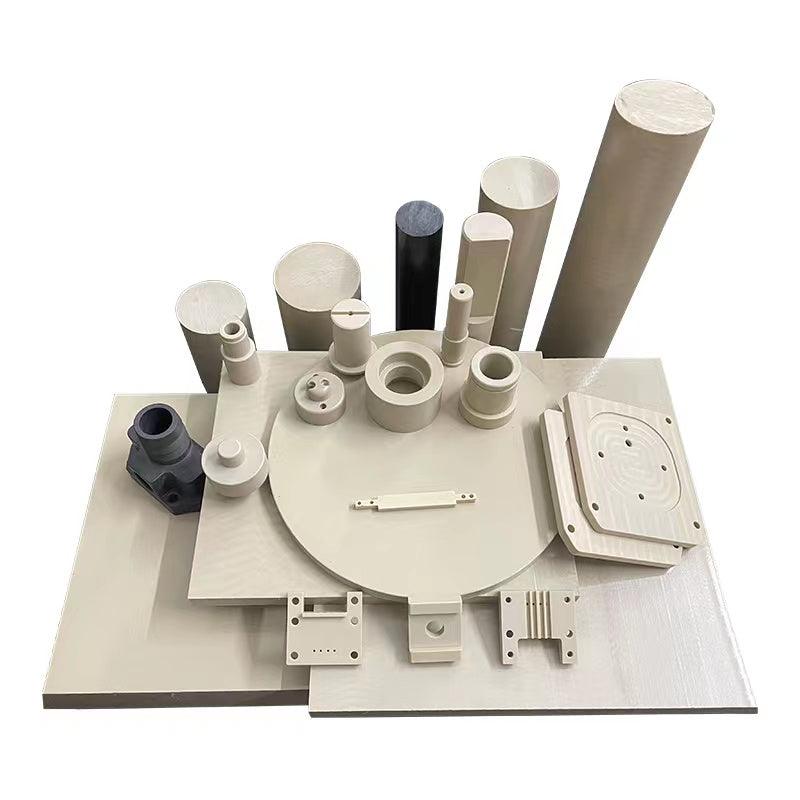

Custom POM/Acetal/Delrin® Machining Services

Precision Gears & Drive Components

- Spur, helical, bevel, worm gears

- Module range: 0.3 to 8

- Gear cutting & hobbing services

- Replaces metal gears - 80% weight reduction

- Self-lubricating, quiet operation

Fixtures, Jigs & Tooling Components

- Positioning plates & alignment guides

- Assembly fixtures & work holders

- Wear plates & slide guides

- Dimensional stability under load

- Replaces aluminum at lower cost

Bushings, Bearings & Wear Parts

- Plain bearings & sleeve bushings

- Thrust washers & wear strips

- Self-lubricating design

- Outlasts bronze & nylon alternatives

- Chemical resistant formulations

POM/Acetal Parts Portfolio

Our POM/Acetal Manufacturing Process

Design Analysis

Free DFM review for manufacturability

Material Selection

POM-C vs POM-H optimization

Precision Machining

CNC milling/turning ±0.03mm

Quality Control

100% dimensional inspection

Fast Delivery

Global shipping 3-5 days

POM/Acetal/Delrin® Industry Applications

🚗 Automotive Industry

Fuel system components, door mechanisms, seatbelt parts, steering columns, window regulators, interior clips

⚙️ Industrial Machinery

Conveyor components, pump impellers, valve seats, chain guides, rollers, cam followers

🏥 Medical Devices

Surgical instruments, insulin pens, drug delivery devices, diagnostic equipment parts, dental tools

📱 Electronics & Electrical

Connectors, switches, relay components, printer gears, copier parts, keyboard mechanisms

🍴 Food & Beverage Equipment

Valves, fittings, bottling equipment, food processing machinery components, dairy equipment parts

🏢 Consumer Products

Zippers, buckles, handles, locks, plumbing fixtures, appliance components

POM vs Alternative Engineering Plastics

| Property | POM/Acetal | Nylon 6 | UHMW-PE | PEEK | PTFE |

|---|---|---|---|---|---|

| Dimensional Stability | Excellent | Good* | Excellent | Excellent | Excellent |

| Machinability | Best | Excellent | Good | Good | Difficult |

| Strength | High | High | Moderate | Very High | Low |

| Wear Resistance | Excellent | Excellent | Outstanding | Excellent | Good |

| Chemical Resistance | Good | Good | Excellent | Outstanding | Best |

| Temperature Range | -40°C to +100°C | -30°C to +80°C | -200°C to +80°C | -50°C to +250°C | -200°C to +260°C |

| Cost | $$ | $$ | $$$ | $$$$ | $$$$ |

*Nylon absorbs moisture affecting dimensional stability

Complete POM/Acetal Fabrication Services

Frequently Asked Questions About POM/Acetal/Delrin®

POM (Polyoxymethylene) is the chemical name for this engineering plastic. Acetal is the common industry term for POM. Delrin® is DuPont's brand name for their homopolymer POM (POM-H). All three terms refer to the same family of materials, with Delrin® specifically being a homopolymer version while generic Acetal can be either copolymer (POM-C) or homopolymer (POM-H).

POM-C (Copolymer Acetal) offers better chemical resistance, lower internal stress, better dimensional stability, and is easier to process. It's ideal for most applications.

POM-H (Homopolymer/Delrin®) provides slightly higher mechanical strength, stiffness, and temperature resistance. Choose it for high-load mechanical applications requiring maximum strength.

Our standard CNC machining tolerance for POM/Acetal/Delrin® parts is ±0.03mm (±0.0012"). For critical features, we can achieve tolerances as tight as ±0.01mm through specialized processes. POM's excellent dimensional stability and low thermal expansion make it ideal for precision components.

Yes! POM successfully replaces metals like brass, aluminum, and steel in many applications. Benefits include: 80% weight reduction vs steel, self-lubrication (no grease needed), corrosion resistance, lower manufacturing costs, quieter operation, and electrical insulation. Common replacements include brass gears, bronze bushings, aluminum brackets, and steel pins.

We have NO minimum order quantity! We can machine a single prototype or produce 10,000+ parts. Our flexible manufacturing capabilities include: single piece prototypes, small batch production (10-100 pcs), medium volume (100-1,000 pcs), and high volume production (1,000+ pcs) with injection molding options.

We stock a wide range of POM materials in various colors including Natural (white/off-white), Black, Blue, and other custom colors upon request. We offer both POM-C (copolymer) and POM-H (homopolymer) grades to suit different application requirements. Special formulations like glass-filled, PTFE-enhanced, and UV-stabilized grades are also available for specific performance needs.

Lead times depend on complexity: Simple parts: 2-3 business days | Standard parts: 5-7 business days | Complex assemblies: 7-10 business days | Production runs: 2-3 weeks. Rush service available for urgent projects. We provide accurate timelines with every quote.

We accept all standard CAD formats: STEP, IGES, STL, DWG, DXF, PDF drawings, SolidWorks, Fusion 360, AutoCAD files. If you only have hand sketches or samples, we can help with reverse engineering and CAD design services.

Explore Our Complete Engineering Plastics Portfolio

In addition to POM/Acetal/Delrin®, we offer comprehensive machining and materials for all engineering plastics:

Chemical Tanks & Cutting Boards UHMW-PE

Wear Strips & Liners Nylon

Gears & Bearings PEEK

Aerospace & Medical PTFE/Teflon

Seals & Gaskets Acrylic

Displays & Guards Polycarbonate

Safety Shields ABS

Housings & Enclosures PVC

Pipes & Fittings G10/FR4

Electrical Insulators

Start Your POM/Acetal/Delrin® Project Today

Join thousands of engineers who trust Beeplastic for precision Polyoxymethylene solutions.

Expert guidance • Competitive pricing • Fast turnaround • No minimum order

📧 beeplastic@beeplastic.com | Response within 24-48 hours

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog