You will not be allowed to compare more than 4 products at a time

View compare

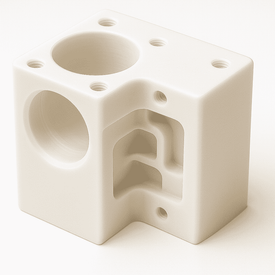

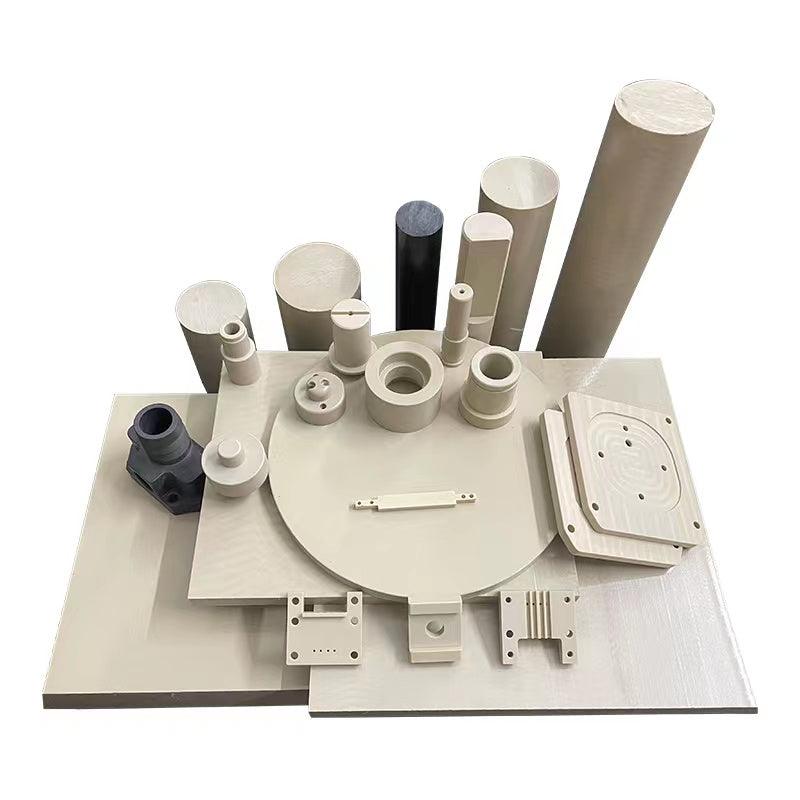

Precision Machining of ABS Plastic Components

Beeplastic provides expert custom machining and fabrication services for ABS plastic, one of the most versatile and reliable thermoplastics. We transform ABS sheets, rods, and 3D printing filaments into durable, impact-resistant parts with excellent aesthetics, tailored precisely to your designs.

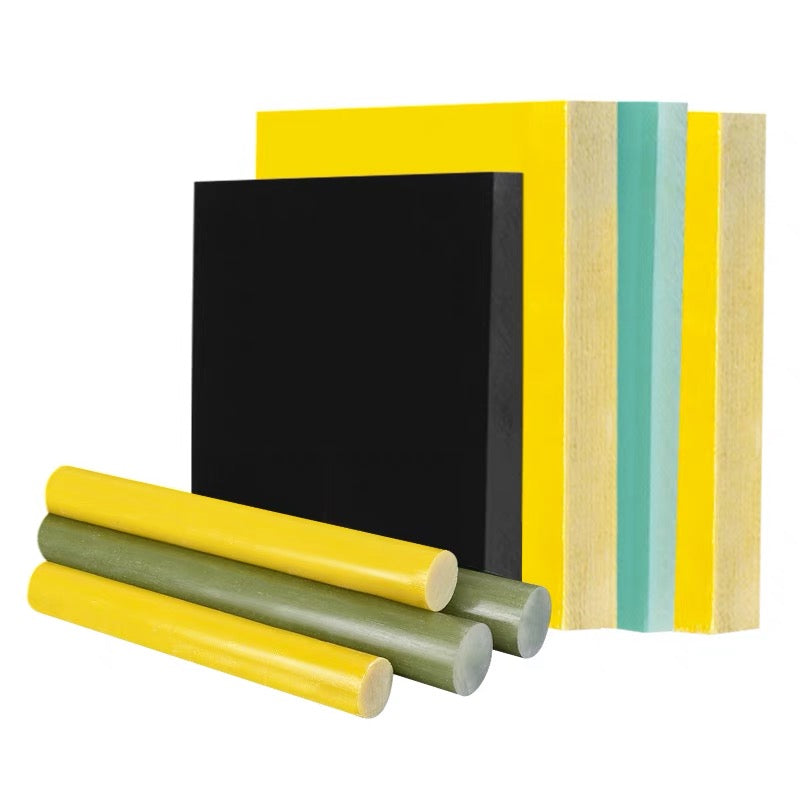

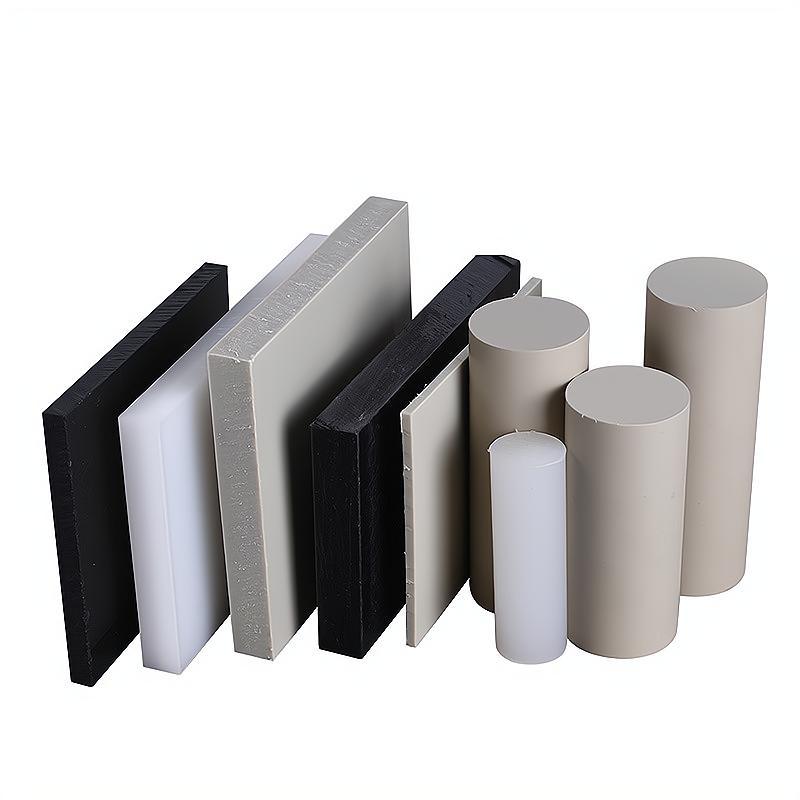

ABS Plastic Stock Shapes: Sheets & Rods for Fabrication

Beeplastic supplies high-quality, versatile ABS (Acrylonitrile Butadiene Styrene) in two primary stock forms: sheets and solid rods. Both are engineered to provide excellent machinability and serve as the ideal foundation for creating durable, impact-resistant custom parts.

Shared Core Advantages

Key Advantages of Fabricating with ABS Plastic

- Excellent Impact Resistance & Toughness: ABS is renowned for its durability and ability to withstand significant impact, making it ideal for creating protective housings, automotive parts, and consumer goods.

- Superior Machinability & Thermoformability: One of the easiest thermoplastics to CNC machine, mill, drill, and turn. It also thermoforms exceptionally well, allowing for the creation of complex custom shapes.

- Great Aesthetics & Surface Finish: Provides a high-quality, smooth surface that is easily painted, glued, or decorated. We offer ABS in various colors and textured or smooth finishes to match your design needs.

- Cost-Effective & Reliable Solution: Offers a fantastic balance of robust performance, durability, and price, making it a highly cost-effective material choice for both prototyping and end-use production parts.

Precision Machining of ABS Plastic Components

Premium ABS Plastic Machining Services & Materials

Expert Acrylonitrile Butadiene Styrene (ABS) CNC Machining, Fabrication & Stock Materials for Industrial, Automotive, Electronics & Consumer Applications

Why ABS Plastic is the Go-To Material for Modern Manufacturing

Acrylonitrile Butadiene Styrene (ABS) stands as one of the most versatile and widely used engineering thermoplastics in contemporary manufacturing. Renowned for its exceptional balance of mechanical strength, impact resistance, and machinability, ABS has become the preferred choice for industries spanning automotive, consumer electronics, medical devices, and industrial equipment.

At Bee Plastic, we specialize in precision ABS plastic machining, custom fabrication, and material supply. Whether you need complex CNC-machined components, standard ABS sheets and rods, or rapid prototyping services, our advanced manufacturing capabilities and material expertise ensure superior results for every project—no matter the size or complexity.

Why Choose ABS Plastic Material?

Understanding the core advantages that make ABS thermoplastic the preferred choice for demanding applications

Outstanding Impact Resistance & Toughness

ABS plastic delivers exceptional impact strength and durability, making it ideal for parts that must withstand mechanical stress, drops, and physical wear. The butadiene component provides superior toughness while maintaining structural integrity even under repeated impact.

Superior Machinability & Precision

Machine-grade ABS is specifically formulated for CNC machining, milling, turning, and drilling operations. It produces clean cuts with minimal tool wear, accepts tight tolerances (±0.03mm), and delivers excellent surface finishes without extensive post-processing.

Cost-Effective Manufacturing Solution

Compared to high-performance engineering plastics like PEEK or Ultem (PEI), ABS provides an economical solution without sacrificing performance. Lower material costs combined with excellent machinability reduce both material waste and production time.

Excellent Surface Finish & Aesthetics

ABS naturally produces smooth, matte surfaces that are ideal for painting, printing, plating, or leaving as-is. Its ability to achieve high-quality aesthetic finishes makes it perfect for consumer-facing products, enclosures, and decorative components.

Good Thermal Stability & Performance

With a heat deflection temperature between 80-85°C (176-185°F), ABS maintains dimensional stability and mechanical properties across a wide operating temperature range, making it suitable for automotive components and electronic housings that generate heat.

Chemical Resistance Properties

ABS demonstrates good resistance to acids, alkalis, and many common chemicals. While not as chemically inert as PTFE or PVDF, it performs reliably in environments involving oils, greases, dilute acids, and alkaline solutions.

ABS Plastic Technical Properties & Performance Data

Verified material specifications from certified testing (SGS Report)

ABS Plastic Sheets, Rods & Stock Materials

Comprehensive selection of ABS materials in various forms, sizes, and grades

Standard ABS Stock Materials

Bee Plastic offers a comprehensive selection of ABS plastic materials in various forms, sizes, and grades to meet your specific project requirements. All materials are sourced from reputable manufacturers and meet international quality standards.

ABS Plastic Sheets

Our ABS sheets are available in multiple thicknesses from 1mm to 50mm and standard dimensions up to 1220mm × 2440mm (4' × 8'). We also provide custom-cut sheets to your exact specifications.

- Standard black and natural (off-white) colors available

- Machine-grade ABS optimized for CNC fabrication

- Extruded sheets for consistent quality

- Smooth finish on both sides for easy processing

- Perfect for panels, guards, housings, and enclosures

ABS Plastic Rods & Bars

ABS rods are available in diameters from 10mm to 200mm and lengths up to 3000mm. Ideal for turning operations and cylindrical components.

- High dimensional accuracy and straightness

- Excellent for bushings, spacers, and mechanical parts

- Can be easily machined to tight tolerances

- Custom lengths available - no minimum order quantity

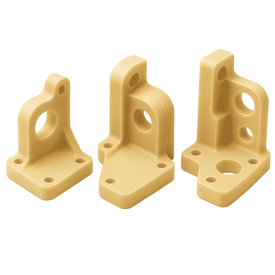

Comprehensive ABS Plastic Machining & Fabrication Services

From concept to completion - we transform ABS material into precision components

Precision CNC Machining for ABS Plastic

Our state-of-the-art CNC machining capabilities enable us to produce complex ABS components with exceptional accuracy and repeatability. We utilize multi-axis CNC mills, lathes, and routers specifically calibrated for thermoplastic materials.

CNC Milling & Routing Services

- 3-axis, 4-axis, and 5-axis CNC milling capabilities

- Precision tolerance of ±0.03mm (±0.0012")

- Complex geometries including undercuts, pockets, and intricate features

- Optimal feed rates and cutting speeds to prevent heat buildup

- Specialized tooling for ABS to minimize chipping

CNC Turning & Lathe Operations

- Precision turning for cylindrical ABS parts

- Threading, grooving, and boring operations

- Tight concentricity and surface finish control

- Ideal for shafts, bushings, spacers, and rotational components

Cut-to-Size Service

Precision cutting of ABS sheets and rods to your exact dimensions. Water jet, saw cutting, and routing available for custom sizes.

Learn More →Laser Cutting & Engraving

CO2 laser cutting for intricate patterns, holes, and designs in ABS sheets with smooth, polished edges and precise details.

Learn More →Injection Molding

High-volume ABS injection molding for production runs. Ideal for complex parts with consistent quality and repeatability.

Learn More →Thermoforming & Bending

Heat forming ABS sheets into 3D shapes, curves, and contours for enclosures, covers, and custom formed components.

Learn More →Plastic Welding

Professional ABS welding services including hot gas, ultrasonic, and solvent welding for assemblies and repairs.

Learn More →Design & Engineering Support

DFM analysis, material selection guidance, and process optimization recommendations to ensure project success.

Contact Us →Diverse Industry Applications of ABS Plastic

From automotive to medical - ABS serves critical functions across industries worldwide

🚗 Automotive Industry

- Dashboard components and instrument panels

- Interior trim, door panels, and console parts

- Wheel covers and exterior trim pieces

- Steering wheel components and bezels

- Air conditioning ducts and vents

- Protective covers and housings

💻 Consumer Electronics

- Computer and laptop housings

- Monitor bezels and stands

- Keyboard components and keys

- Remote control cases

- Smartphone and tablet accessories

- Audio equipment enclosures

🏥 Medical Devices

- Non-implantable device housings

- Diagnostic equipment enclosures

- Surgical instrument handles

- Medical trays and containers

- Laboratory equipment components

- Protective covers for medical devices

🏭 Industrial Equipment

- Machine guards and safety covers

- Control panel enclosures

- Tool handles and housings

- Gears, bushings, and bearings

- Conveyor components

- Jigs, fixtures, and tooling aids

🏠 Consumer Products

- Appliance housings and components

- Vacuum cleaner parts

- Kitchen appliance components

- Luggage and travel cases

- Sporting goods and recreational equipment

- Toys and educational products

⚡ Electrical & Electronics

- Electrical enclosures and junction boxes

- Cable management systems

- Light fixture components

- Switch and outlet covers

- Electrical insulators

- Battery housings and compartments

Why Choose Bee Plastic for ABS Machining?

Your trusted partner for precision ABS plastic manufacturing

Precision Expertise

Extensive experience machining ABS and other thermoplastics. We understand material behavior, optimal cutting parameters, and how to achieve the tightest tolerances (±0.03mm) consistently.

No Minimum Order Quantity

Whether you need a single prototype or thousands of production parts, we accept projects of all sizes. This flexibility allows you to test designs and iterate quickly.

Fast Turnaround Times

Efficient processes and dedicated production capacity enable quick turnaround. Standard lead times: 3-5 days for simple parts, 5-10 days for complex components.

Free Shipping Available

Complimentary standard shipping to many regions for qualifying orders. Expedited shipping options available at competitive rates when you need parts urgently.

Advanced Equipment

State-of-the-art CNC machines, laser cutters, and fabrication equipment ensure superior quality. Machines are specifically calibrated for plastic machining.

Engineering Support

Technical team provides DFM feedback, material selection guidance, and process optimization recommendations to ensure your project succeeds.

Our ABS Plastic Machining Process

A streamlined workflow from quote to delivery

Request a Quote

Submit your project details, drawings (CAD files preferred), material requirements, and specifications through our online quote form. Our team reviews your requirements within 24 hours and provides a detailed quotation.

Design Review & DFM Analysis

Our engineering team analyzes your design for manufacturability, identifies potential issues, and provides optimization suggestions to improve quality and reduce costs. We ensure your design is production-ready.

Material Selection & Sourcing

We help you select the optimal ABS grade for your application and source high-quality materials. We stock common sizes and can procure special materials as needed.

CNC Programming & Setup

Our programmers create optimized CNC toolpaths, select appropriate cutting tools, and set up fixtures to ensure precision and efficiency during machining operations.

Precision Machining

Parts are machined using controlled cutting speeds, appropriate coolants, and sharp tooling to prevent heat buildup and achieve excellent surface finishes. In-process inspections ensure accuracy.

Quality Inspection & Finishing

Every part undergoes dimensional inspection using precision measuring equipment. Secondary operations like deburring, polishing, or assembly are performed as specified.

Packaging & Delivery

Parts are carefully packaged to prevent damage during shipping. We coordinate with reliable carriers to ensure safe, timely delivery to your location.

ABS Machining Technical Specifications

Detailed capabilities and tolerances for precision manufacturing

| Specification | Standard Capability | Notes |

|---|---|---|

| Machining Tolerance | ±0.03mm (±0.0012") | Standard precision; tighter tolerances available upon request |

| Surface Finish | Ra 1.6 μm standard | Finer finishes achievable with additional processing |

| Maximum Sheet Size | 1220mm × 2440mm (4' × 8') | Larger custom sizes available upon request |

| Sheet Thickness Range | 1mm - 50mm | Custom thicknesses can be sourced |

| Rod Diameter Range | 10mm - 200mm | Various lengths up to 3000mm |

| Minimum Feature Size | 0.5mm typical | Depends on geometry and tooling |

| Thread Sizes | M2 - M30 (metric) #2-56 - 1" (imperial) |

Custom threads available |

| Hole Diameter Accuracy | ±0.025mm for Ø ≤ 6mm ±0.05mm for Ø > 6mm |

Reaming available for critical holes |

ABS vs. Other Engineering Plastics

Understanding how ABS compares to alternative materials for informed material selection

Material Selection Guidance: While ABS offers an excellent balance of properties and cost-effectiveness, other materials may be more suitable depending on your specific requirements such as temperature resistance, chemical compatibility, UV exposure, or mechanical demands. Our technical team can help you select the optimal material for your application.

| Property | ABS | Nylon (PA) | Polycarbonate (PC) | Acrylic (PMMA) |

|---|---|---|---|---|

| Impact Resistance | Excellent (22-24 kJ/m²) | Good | Excellent | Fair |

| Rigidity / Stiffness | Good (2290-2450 MPa) | Excellent | Good | Excellent |

| Machinability | Excellent | Excellent | Good | Excellent |

| Chemical Resistance | Good | Excellent | Good | Fair |

| UV Resistance | Fair (requires UV stabilizers) | Fair | Good | Excellent |

| Temperature Resistance | 80-85°C (HDT) | 80-150°C | 125-135°C | 75-95°C |

| Relative Cost | Low-Moderate | Moderate | Moderate-High | Low-Moderate |

Frequently Asked Questions About ABS Plastic Machining

What is the difference between machine-grade ABS and regular ABS?

Machine-grade ABS is specifically formulated with properties optimized for CNC machining operations. It has better dimensional stability, reduced internal stress, and more consistent material properties compared to ABS formulated for injection molding or extrusion. This results in cleaner cuts, less warping, and better surface finishes when machining.

Can ABS be used outdoors or in direct sunlight?

Standard ABS has limited UV resistance and can degrade, yellow, and become brittle when exposed to prolonged sunlight. However, UV-stabilized ABS grades are available for outdoor applications. Alternatively, parts can be painted or coated with UV-protective finishes. For extended outdoor use, materials like ASA (a weather-resistant ABS variant), HDPE, or PVDF may be better choices.

What tolerances can you achieve with ABS machining?

Our standard machining tolerance for ABS is ±0.03mm (±0.0012"). For critical dimensions, we can achieve tighter tolerances of ±0.013mm (±0.0005") with additional process controls. Tolerances depend on part geometry, size, and specific features. Contact us with your drawings for specific tolerance capabilities on your project.

How does ABS compare to polycarbonate (PC)?

Both materials offer excellent impact resistance, but PC has superior impact strength and higher temperature resistance (up to 135°C vs. 85°C for ABS). However, ABS is easier to machine, more cost-effective, and produces better surface finishes. ABS is opaque while PC can be transparent. For applications not requiring PC's extreme impact resistance or transparency, ABS is often the more economical choice.

Can you weld or bond ABS parts together?

Yes, ABS can be joined using several methods: solvent welding (using ABS cement or MEK/acetone), hot gas welding, ultrasonic welding, and mechanical fastening. Solvent welding creates very strong joints that are nearly as strong as the parent material. We offer plastic welding services for ABS assemblies.

What surface finishes are available for ABS parts?

Machined ABS naturally has a matte finish. We can provide various surface finishes including: as-machined (matte), sanded/polished (semi-gloss to gloss), bead blasted (uniform matte texture), or painted/coated. ABS accepts paint, plating, printing, and other decorative finishes exceptionally well.

What is your minimum order quantity for machined ABS parts?

We have NO minimum order quantity. Whether you need a single prototype part or 10,000 production pieces, we can accommodate your project. This flexibility makes us ideal for R&D, prototyping, short runs, and production manufacturing.

How long does ABS plastic machining take?

Lead times depend on project complexity, quantity, and current production schedule. Typical turnaround times are: Simple parts (3-5 business days), Complex parts or moderate quantities (5-10 business days), Large production runs (2-4 weeks). Rush services are available for urgent projects.

Can you machine ABS parts with very thin walls?

Yes, but with considerations. ABS can be machined to thin wall sections (1-2mm), but care must be taken to prevent warping, vibration, and breakage during machining. Proper fixturing, sharp tools, and controlled cutting parameters are essential. We recommend minimum wall thickness of 2-3mm for best results, though thinner is possible depending on geometry.

Do you offer color options for ABS materials?

We primarily stock natural (off-white) and black ABS materials. Custom colors can be sourced upon request, though this may affect lead times and pricing. Alternatively, parts can be painted or coated to achieve any desired color after machining.

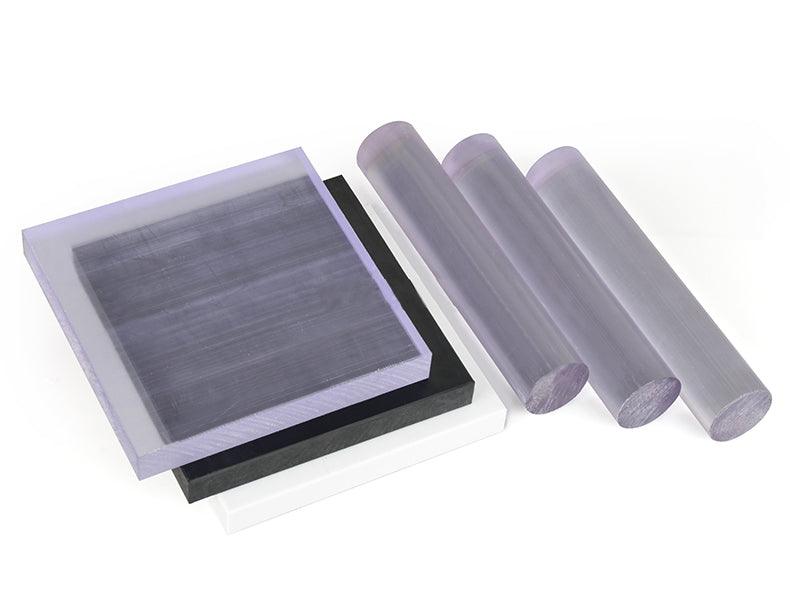

Explore Our Complete Range of Engineering Plastics

Beyond ABS - we machine and supply a comprehensive selection of high-performance materials

Not sure if ABS is right for your application? Browse our complete material selection below or contact our technical team for personalized material recommendations based on your specific requirements for temperature resistance, chemical compatibility, mechanical strength, and budget constraints.

| Material | Full Name | Key Properties & Advantages | Typical Applications |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene | Good impact resistance, easy to machine, cost-effective | Automotive parts, electronic housings, consumer goods |

| PEEK | Polyether Ether Ketone | Exceptional high-temp strength, chemical resistance, biocompatible | Aerospace, medical implants, high-performance bearings |

| POM (Acetal) | Polyoxymethylene | Excellent machinability, low friction, high stiffness | Precision gears, bearings, fuel system components |

| Polycarbonate (PC) | Polycarbonate | Extreme impact resistance, optical clarity, dimensionally stable | Safety glasses, machine guards, electronic housings |

| Acrylic (PMMA) | Polymethyl Methacrylate | Excellent optical clarity, UV resistant, easily fabricated | Displays, lenses, signage, aquariums |

| Nylon (PA) | Polyamide | High strength, excellent wear resistance, self-lubricating | Gears, bearings, structural components |

| HDPE | High-Density Polyethylene | Excellent chemical resistance, impact resistant | Chemical tanks, cutting boards, food processing |

| UHMW-PE | Ultra-High-Molecular-Weight Polyethylene | Exceptional wear resistance, low friction, self-lubricating | Wear strips, conveyor components, bearings |

| PTFE | Polytetrafluoroethylene | Extremely low friction, outstanding chemical inertness | Seals, gaskets, chemical processing components |

| Polypropylene (PP) | Polypropylene | Excellent chemical resistance, low density | Chemical containers, automotive parts, medical labware |

| PET | Polyethylene Terephthalate | High strength, excellent clarity (PETG) | Food containers, machine guards, display stands |

| PEI (Ultem) | Polyetherimide | High strength at elevated temps, flame retardant, sterilizable | Medical devices, aircraft interiors, electrical components |

| PPS | Polyphenylene Sulfide | High-temperature resistance, chemical resistance, flame retardant | Automotive under-hood, pump parts, electrical connectors |

| PVC | Polyvinyl Chloride | Good chemical resistance, flame retardant, cost-effective | Pipes, chemical tanks, electrical insulation |

| PVDF | Polyvinylidene Fluoride | Excellent chemical resistance, high purity, UV resistant | Chemical processing, high-purity fluid handling |

| Polyimide (PI) | Polyimide | Outstanding high-temperature performance, dimensional stability | Aerospace components, semiconductor processing |

| PAI | Polyamide-imide | Exceptional strength at high temperatures, excellent wear resistance | High-performance seals, bearings, aerospace components |

| Polyurethane (PU) | Polyurethane | Wide range of hardness, excellent abrasion & tear resistance | Seals, gaskets, wheels, shock absorbers |

| G-10 / FR-4 | Glass-Reinforced Epoxy Laminate | Exceptional strength, electrical insulation, flame retardant | PCBs, structural components, electrical insulators |

| Bakelite (Phenolic) | Phenol Formaldehyde Resin | Superior electrical insulation, high rigidity, heat resistance | Electrical insulators, terminal boards, switchgear |

| Phenolic Cloth | Phenolic Cotton Cloth Laminate | Exceptional mechanical strength, superior wear resistance | Mechanical gears, bearings, wear pads, structural parts |

| Silicone Rubber | Silicone Rubber (SR/VMQ/LSR) | Excellent thermal stability, biocompatible, flexible | Seals, gaskets, medical tubing, wearable tech components |

See How We've Helped Other Clients: Explore our case studies and success stories to see real-world applications of our ABS machining capabilities across various industries and learn how we've solved complex manufacturing challenges.

Ready to Start Your ABS Plastic Machining Project?

Get a free quote today and experience precision, quality, and exceptional service

No Minimum Order • Fast Turnaround • Expert Engineering Support

Request a Free QuoteOur Complete Manufacturing Capabilities

Comprehensive plastic fabrication services under one roof

CNC Machining

Multi-axis milling, turning, and routing for complex geometries and tight tolerances.

Learn More →Cut-to-Size Service

Precision cutting of sheets and rods to your exact specifications.

Learn More →ABS in Action: From Prototypes to Production Parts

Explore how our precision CNC machining of ABS plastic delivers reliable, high-performance components for a variety of demanding industrial and prototyping applications.

YOUR RELIABLE FABRICATION PARTNER

Always Here To Support Your ABS Project

We are more than just a manufacturer; we are your project partner. Our team is committed to providing responsive service, expert technical support, and transparent communication from your initial inquiry to final delivery.

Direct Engineering & Sales Support

beeplastic@beeplastic.comOur Facility Address & Hours

Building 3, Dezheng Middle Road, Chang'an Town, Dongguan City, Guangdong Province, China 【Mon to Sat - 08:00 - 22:00】START YOUR CUSTOM FABRICATION PROJECT

Let's Build Your Custom ABS Components

Our Engineering Team is ready to turn your designs into high-quality, precision-machined ABS parts. Upload your CAD files and project requirements below for a comprehensive review and a competitive, no-obligation quote.

Tailored Solutions Across Industries

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog