You will not be allowed to compare more than 4 products at a time

View compareDescription

Why Choose Us

Free shipping & Returns

Reviews

Description

High-Performance Engineering Plastic for Extreme Conditions

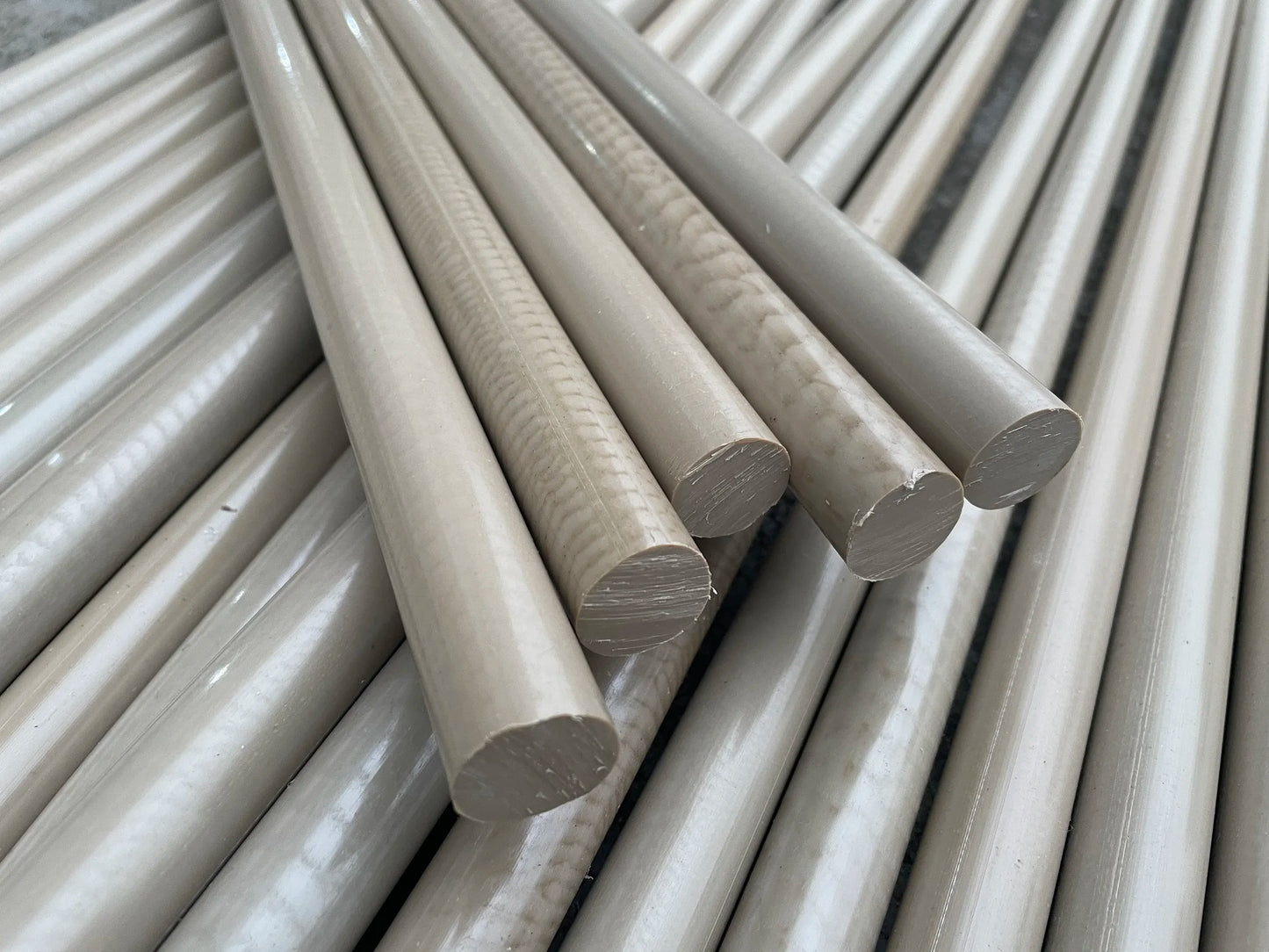

Our PEEK rods are designed to meet the demands of high-temperature, high-load, and chemically aggressive environments. With outstanding resistance to wear, hydrolysis, and chemicals, these rods are perfect for CNC machining, custom parts fabrication, and precision industrial components. 💡

Available in diameters from 3mm (1/8") to 150mm (5-7/8") and lengths of 50mm (2"), 80mm (3-1/8"), and 100mm (4"), BeePlastic provides both standard and fully customized PEEK rod options for engineers, designers, and manufacturers across industries.

Durable. Machinable. Dependable.

PEEK (Polyetheretherketone) is known for its exceptional mechanical strength and dimensional stability. Whether you're crafting parts for aerospace, automotive, electronics, or medical devices, our rods deliver reliability you can count on.

-

⚙️ Heat Resistance: Withstands up to 260°C (500°F) continuous operation

-

🧪 Chemical Stability: Excellent resistance to acids, bases, solvents

-

🛠️ Easy to Machine: Compatible with CNC, milling, drilling, and turning

-

🧩 Customizable: Any size, cut, or finish to match your design

Industrial Applications of PEEK Rods

Our high-temperature plastic rods are ideal for applications including:

-

Gear housings, seals, and wear plates in automotive systems

-

Turbine components and insulators in aerospace

-

Sterilizable parts in medical equipment

-

Electrical insulators and connectors in electronics

-

Sliding elements in food processing and packaging machinery

These rods are engineered for both functional prototyping and end-use component production in demanding industries.

Full Size Range with Metric/Inch Display

Choose from a wide range of diameters and lengths to match your project:

-

Length Options: 50mm (2"), 80mm (3-1/8"), 100mm (4")

-

Diameter Options (with inch):

3mm (1/8"), 4mm (5/32"), 5mm (3/16"), 6mm (1/4"), 8mm (5/16"),

10mm (3/8"), 12mm (1/2"), 15mm (5/8"), 20mm (4/5"), 25mm (1"),

30mm (1-3/16"), 35mm (1-3/8"), 40mm (1-5/8"), 50mm (2"),

60mm (2-3/8"), 70mm (2-3/4"), 75mm (3"), 80mm (3-1/8"),

90mm (3-1/2"), 100mm (4"), 120mm (4-3/4"), 150mm (5-7/8")

Looking for other sizes? We offer flexible custom production – just send us your requirements.

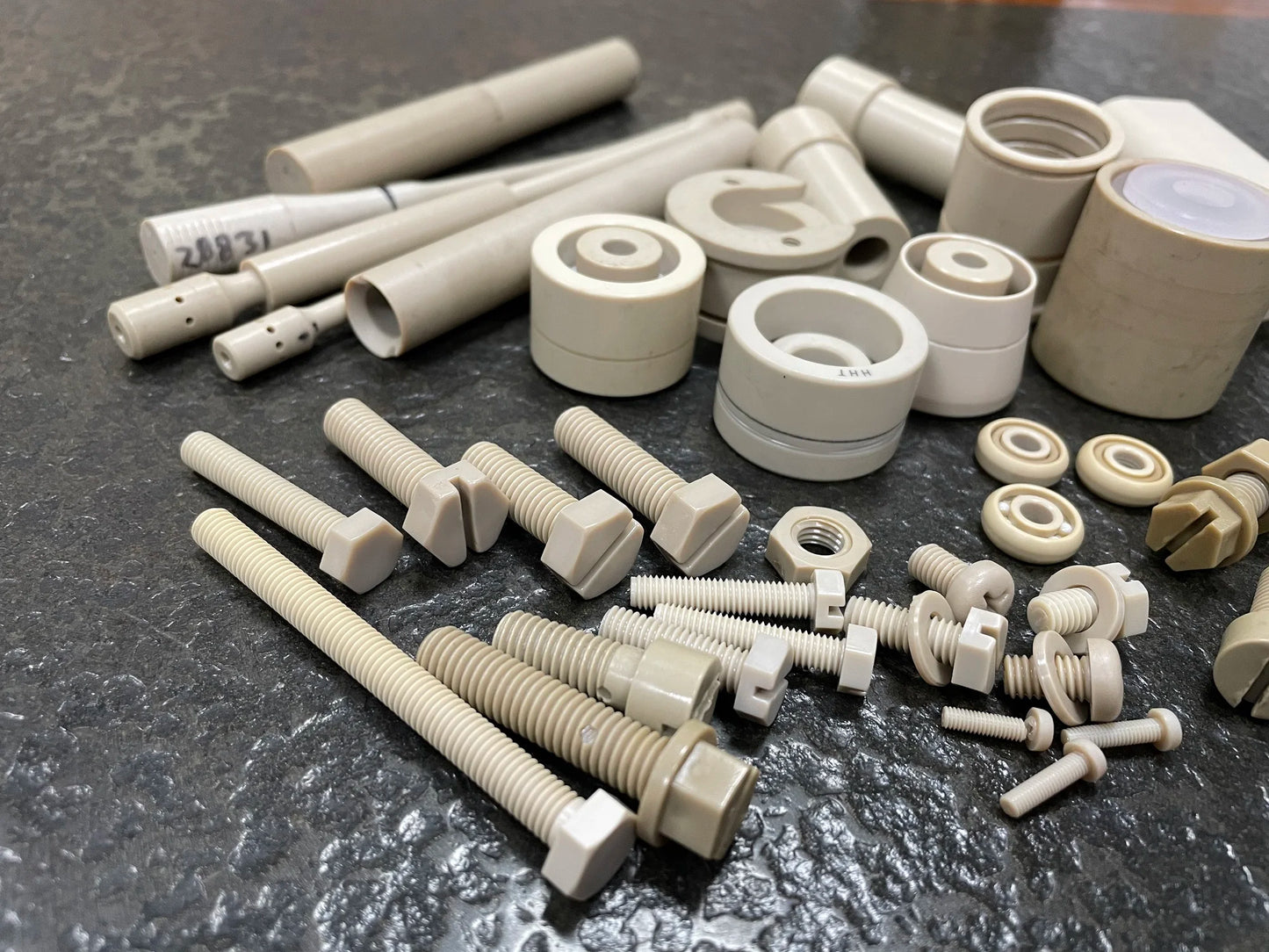

Custom Machining Services You Can Trust

Need more than just rods? BeePlastic supports full-service custom plastic machining, including:

-

Hole drilling, edge rounding, chamfering

-

Sample production and low-volume trial orders

Upload your drawing or request a free consultation—our team is here to bring your design to life.

Why Choose BeePlastic 💼

-

🧵 Plastic Variety Leader: From PEEK to PTFE, PEI, Acrylic, and more—we stock it all

-

🛠️ In-House Precision Machining: CNC, laser, polishing, and drilling—custom work is our core

-

🤝 Customer-First Approach: Flexible MOQs, fast response, and real engineers to support your project

-

💸 Save on Costs: We help reduce material waste and labor time by delivering ready-to-assemble solutions

Whether you’re a startup building your first prototype or an established manufacturer scaling production, BeePlastic helps you save time, reduce expenses, and get to market faster.

Technical Specifications

-

Material: Virgin or glass fiber-reinforced PEEK

-

Color: Natural (beige)

-

Temperature Resistance: Up to 260°C / 500°F

-

Tensile Strength: Approx. 90~100 MPa

-

Density: 1.3–1.45 g/cm³

-

Water Absorption: < 0.1%

-

Customization: Available on all specifications and shapes

Frequently Asked Questions

Q: Can I machine this PEEK rod using standard CNC tools?

A: Yes! PEEK is one of the best plastics for CNC machining. We can also provide you with pre-machined parts if needed.

Q: Do you offer custom diameters or shapes?

A: Absolutely. Just send us your drawing or idea—we offer cut-to-size and fully custom shapes.

Q: Is there a minimum order?

A: We accept both small trial orders and bulk quantities. Contact us for details based on your needs.

Q: How fast is delivery?

A: Standard sizes ship in 3–5 business days. Custom orders are typically ready in 7–12 business days.

Q: Can you ship internationally?

A: Yes, we support global shipping with tracking and offer free standard shipping in many cases.

🛒 Ready to Order? Let’s Build It Your Way

Choose your size, add to cart, and enjoy fast delivery.

Need a custom shape or finish? Click below to get a fast quote—no engineering jargon required.

👉 [Buy Now – Standard Sizes]

👉 [Request a Custom Quote]

BeePlastic is committed to delivering quality, speed, and value—because your project deserves the best. Let's build together. ✨

Why Choose Us

Your Strategic Partner for High-Performance Plastic Manufacturing & Supply

In industries where performance, reliability, and precision are paramount, your choice of a manufacturing partner is a critical decision. For over 15 years, BeePlastic has been the trusted source for engineers and procurement managers who require flawless execution, from complex custom components to a reliable supply of high-grade raw materials.

Engineered for Partnership: How We De-Risk Your Supply Chain

We understand that our role is to provide certainty. Our entire operation is built on a foundation of rigorous processes designed to deliver predictable excellence and give you peace of mind.

A Collaborative Approach

We begin every partnership by becoming an extension of your team. Our mandatory Tri-Departmental DFM (Design for Manufacturability) Summit ensures that your design is not just manufacturable, but optimized for performance, cost, and longevity. This proactive, consultative process, involving our engineering, production, and service leaders, is our upfront investment in your project's success.

A Commitment to Quality

Precision is not a goal; it's our baseline. We hold a standard tolerance of ±0.03mm (±0.0012") on our CNC machined components. This unwavering commitment to quality is verified through stringent, multi-point inspections. For you, this means reduced assembly friction, predictable performance, and the confidence that every part is a perfect replica of your design.

A Complete Manufacturing Ecosystem

We provide a comprehensive suite of in-house manufacturing capabilities, allowing you to streamline your supply chain and ensure consistent quality from a single, trusted partner.

Precision CNC Plastic Machining

As the cornerstone of our operation, we utilize advanced 3, 4, and 5-axis CNC mills and lathes to produce parts with intricate geometries and tight tolerances. From high-performance materials like PEEK and PTFE to engineering plastics like Nylon and Acetal, our experienced machinists and calibrated equipment deliver unparalleled accuracy and surface finish.

Explore Our CNC Capabilities →

Custom Plastic Fabrication & Assembly

Our capabilities extend far beyond machining. Our skilled fabrication department provides a range of value-added services, including heat bending, plastic welding, chemical bonding, and complex assembly. This allows us to deliver not just components, but complete, fully integrated solutions ready for immediate implementation in your product line.

See Our Fabrication Case Studies →Additional Services & Modern Processes

To support every stage of your product's lifecycle, we also offer scalable injection molding for high-volume production, high-detail laser cutting and engraving for materials like Acrylic, and precision cut-to-size services for raw material preparation.

The Engineer's Material Science Hub

Selecting the optimal material is one of the most critical decisions in product design. This comprehensive guide serves as an authoritative resource for you to compare our inventory of over 22 engineering and high-performance plastics. Our team is always available to provide expert consultation to ensure you make the perfect choice for your application's mechanical, thermal, and chemical requirements.

| Material (Click to Explore) | Common Applications | Key Performance Properties | BeePlastic Machining & Fabrication Insights |

|---|---|---|---|

| ABS | Automotive dashboards, electronic housings | Good impact resistance & toughness, easy to machine | Highly versatile and cost-effective. Ideal for prototypes and aesthetic parts. |

| Acrylic | Point-of-sale displays, lenses, light guides | Excellent optical clarity, UV resistant | Perfect for laser cutting to achieve polished edges. We machine for precision optics. |

| Bakelite (Phenolic) | Electrical insulators, terminal boards, jigs | Superior electrical insulation, high rigidity, heat resistant | We use specific tooling to prevent chipping, delivering smooth, precise insulating components. |

| FR-4 / G-10 | PCBs, insulators, high-strength structural parts | High mechanical strength, flame retardant (FR-4), low moisture absorption | Our expertise prevents delamination while machining these abrasive materials. |

| HDPE | Piping systems, cutting boards, chemical tanks | Excellent chemical resistance, high strength-to-density ratio, FDA grades | Ideal for cost-effective, robust parts. We achieve clean cuts with proper tooling. |

| Nylon (PA) | Gears, bearings, rollers, automotive parts | High mechanical strength, good wear resistance | Excellent for durable, load-bearing parts. We can advise on managing moisture absorption. |

| PAI | High-performance seals, bearings, aerospace parts | Exceptional strength & stiffness at high temperatures | Requires robust tooling. Our experience minimizes part stress and ensures accuracy. |

| PC (Polycarbonate) | Safety glasses, machine guards, electronic housings | Extremely high impact resistance, good clarity | We machine PC to be robust and clear. Stress relief annealing is performed when required. |

| PEEK | Aerospace parts, medical implants, semiconductor parts | Exceptional high-temp & chemical resistance, biocompatible grades | A core specialty. Our proven processes achieve critical precision on PEEK components. |

| PEI | Medical components, aircraft interior parts | High strength at elevated temps, flame retardancy | Ideal for sterilizable parts. We manage specific annealing requirements for stress relief. |

| PET | Beverage bottles, food containers, machine guards | High strength & stiffness, excellent clarity (PETG) | We ensure optimal clarity in machined PETG parts, which offer better impact resistance than Acrylic. |

| PI (Polyimide) | Aerospace components, high-temp insulators | Outstanding high-temperature performance | Demands specialized techniques due to hardness & abrasiveness. We ensure tight tolerances. |

| POM (Acetal) | Precision gears, bearings, fuel system components | High stiffness, low friction, excellent dimensional stability | One of the most machinable plastics. We stock various grades for your specific needs. |

| PP (Polypropylene) | Packaging, automotive components, living hinges | Excellent chemical resistance, low density, weldable | A versatile choice for injection molding and CNC machining in cost-sensitive applications. |

| PPS | Automotive under-hood, pump & valve parts | Excellent high-temp & chemical resistance | Challenging to machine due to its abrasive nature. We use appropriate tooling. |

| PTFE | Non-stick coatings, seals, gaskets, chemical liners | Extremely low friction, outstanding chemical inertness | We employ specialized tooling and techniques (like etching for bonding) to achieve results. |

| PU (Polyurethane) | Seals, gaskets, wheels, shock absorbers | Wide range of hardness, excellent abrasion resistance | Machinability varies with type. We have experience with various forms for custom parts. |

| PVC | Pipes & fittings, window frames, chemical tanks | Good chemical resistance, durable, cost-effective | Rigid PVC machines well. We can advise on the appropriate grade for your application. |

| PVDF | High-purity fluid handling, chemical equipment | Excellent chemical resistance (especially to halogens), UV resistant | We ensure no contamination when processing for high-purity applications. |

| Silicone Rubber | Seals, gaskets, O-rings, medical tubing, keypads | Excellent thermal stability, flexible at low temps, biocompatible | Expertise in silicone molding (LSR, compression), die-cutting, and custom compounding. |

| UHMW-PE | Conveyor components, wear strips, food equipment | Exceptional abrasion resistance, low coefficient of friction | We optimize cutting speeds and use sharp tooling to achieve smooth finishes and prevent melting. |

Let's Build Your Next Great Component

Your project deserves a partner dedicated to precision, quality, and proactive communication. Contact our engineering team today to get a detailed, no-obligation quote and discover the BeePlastic difference.

"BeePlastic provided exceptional custom solutions. Their professionalism and quality are unmatched."

- Satisfied Industrial Client

Free shipping & Returns

Reviews

Frequently Asked Questions (FAQ)

Welcome to our FAQ page! Below you’ll find answers to our most commonly asked questions about shipping times, payment methods, returns, and custom plastic orders. If you can’t find what you’re looking for, feel free to [contact us] or request a custom quote.

📧Contact us📧

01 💭When can I ship my order? 🧠What logistics channels do you use? 💡What are the logistics fees?

💭A: Regular specifications are usually shipped within 48 hours; customized orders depending on the complexity of processing, usually 3~7 days.

🧠A: We use standard distribution logistics for free shipping (usually takes 15~25 days), if you use expedited shipping with multiple logistics (DHL, FedEx, UPS, EMS, FS, etc.), you can choose the most suitable way according to your location and needs. If you need expedited, please contact us to confirm!

💡A: We use our standard delivery logistics by default, no freight charge for standard delivery, if you need fast delivery, you need to contact us for confirmation and charge the freight with the actual quotation of the logistics provider, the specific cost needs to be provided with the receiving address and confirmed with the logistics provider and sent to the customer.

02 💡Can I return or exchange an item?🧠 How do I request a return?

💡A: For regular in-stock products, they can be returned or exchanged within 7 days after receipt (need to keep in good condition). Customized processed or plastic material cut products can not be sold twice, unless quality problem, generally do not support return or exchange.

🧠A: If quality problem, please contact us first by email and provide order number, we will give return address and process. The shipping cost will be borne by the buyer, except for quality issues.

03 💡What payment methods are supported? 🧠What if I can't pay? 💭Can I get a discount for large orders?

💡A: PayPal and bank transfer are the main payment methods on our website. If you need other methods, please contact our customer service.

🧠A: If you are unable to pay or need other ways, please communicate with our customer service, you can submit a contact form to our [Contact us] page or click on the right side of the real-time chat window to leave a message.

💭A: Large orders have corresponding discounts, you can directly communicate with our customer service.

04 💭Can't find the size I need, what custom machining do you offer? 💡What are the MOQ requirements?

💭A: We can cut to specified lengths, thicknesses, diameters, and also do preliminary CNC/lathe machining. Please see the customization page or contact us for details.

💡A: There is no minimum order for regular materials. For CNC or special processing, there may be a certain MOQ requirement; please contact us for details.

05 💭How can I track my order?

💭A: You will receive a confirmation email after placing an order, and the waybill number will be attached after shipment; you can also check the logistics news on the “My Orders” page, or enter the waybill number into [https://www.17track.net/] for inquiry.

Precision Plastic Solutions Tailored to Your Needs

Request a Custom Quote

Every project is unique, and so are your material needs. At BeePlastic, we provide custom-tailored solutions to match your exact specifications. Fill out the form below to get a quote for our high-quality plastic materials, cut and shaped to fit your requirements.