POM plastic, also known as polyoxymethylene or acetal, is a thermoplastic polymer that has high mechanical strength, stiffness, wear resistance, and low friction. It is widely used in engineering and consumer products because of its excellent properties and easy processing. In this blog post, we will answer some common questions about POM plastic and show you how it is applied in various industries and sectors.

What is POM plastic material?

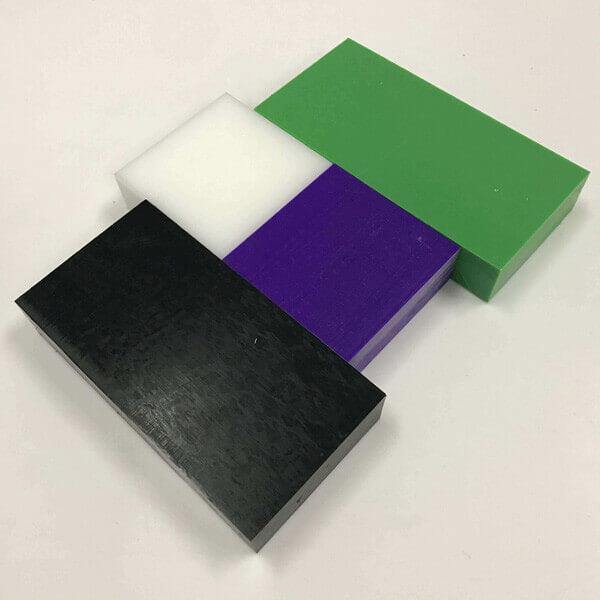

POM plastic is a polymer that consists of repeating units of formaldehyde. There are two types of POM plastic: homopolymer and copolymer. Homopolymer POM is made from pure formaldehyde, while copolymer POM is made from a mixture of formaldehyde and other comonomers, such as ethylene oxide or trioxane. Copolymer POM has better thermal stability, chemical resistance, and impact strength than homopolymer POM, but lower mechanical strength and stiffness.

What are the properties of POM plastic?

POM plastic has many desirable properties that make it suitable for various applications. Some of the main properties of POM plastic are:

- High mechanical strength and stiffness: POM plastic can withstand high loads and stresses without breaking or deforming.

- High wear resistance and low friction: POM plastic has a smooth surface that reduces friction and wear when in contact with other materials. It also has good self-lubricating properties that prevent squeaking and sticking.

- Good dimensional stability and creep resistance: POM plastic does not shrink or expand significantly when exposed to changes in temperature or humidity. It also resists deformation under constant load or stress over time.

- Good electrical insulation and dielectric strength: POM plastic does not conduct electricity and can withstand high voltages without breakdown.

- Good chemical resistance: POM plastic is resistant to most solvents, oils, fuels, acids, bases, and water. It does not corrode or degrade easily when exposed to harsh environments.

- Good thermal resistance: POM plastic can operate in a wide temperature range from -40°C to 120°C. It does not melt or burn easily when heated.

- Easy processing: POM plastic can be molded, extruded, injection molded, blow molded, machined, welded, and bonded using various techniques. It can also be colored, coated, or printed to enhance its appearance or functionality.

Is POM plastic safe?

POM plastic is generally considered to be safe for human health and the environment. It does not contain any toxic substances or heavy metals that could leach out or release harmful gases. It is also biocompatible and can be used for medical devices or implants. However, some precautions should be taken when handling or processing POM plastic:

- Avoid inhaling dust or fumes from cutting, grinding, heating, or burning POM plastic, as they may cause irritation or respiratory problems.

- Wear protective gloves, goggles, and clothing when working with POM plastic, as it may cause skin or eye irritation or allergic reactions.

- Dispose of POM plastic waste properly according to local regulations, as it may pose a fire hazard or environmental pollution if not treated correctly.

How is POM plastic sheet used?

POM plastic sheet is a flat form of POM plastic that can be cut, bent, drilled, or shaped into various sizes and shapes. It is often used for making parts that require high precision, rigidity, and durability. Some examples of POM plastic sheet applications are:

- Gears

- Bearings

- Bushings

- Washers

- Spacers

- Guides

- Slides

- Rollers

- Cams

- Valves

How is POM plastic rod used?

POM plastic rod is a cylindrical form of POM plastic that can be turned, milled, threaded, or carved into various shapes and sizes. It is often used for making parts that require high strength, stiffness, and wear resistance. Some examples of POM plastic rod applications are:

- Shafts

- Pins

- Bolts

- Nuts

- Screws

- Rivets

- Hinges

- Handles

- Knobs

How is POM plastic applied in different industries and sectors?

POM plastic has a wide range of applications in various industries and sectors because of its versatile properties and performance. Some of the main industries and sectors that use POM plastic are:

- Automotive: POM plastic is used for making parts such as fuel injectors, fuel pumps, fuel filters, fuel tanks, door locks, window regulators, seat belts, airbags, steering wheels, pedals, and dashboard components.

- Electrical and electronics: POM plastic is used for making parts such as connectors, switches, relays, circuit breakers, sockets, plugs, cables, wires, and housings.

- Medical and dental: POM plastic is used for making parts such as surgical instruments, implants, prosthetics, orthodontics, dental floss, syringes, and catheters.

- Food and beverage: POM plastic is used for making parts such as food processing equipment, packaging machines, bottles, caps, corks, cans, trays, utensils, and cutlery.

- Textile and clothing: POM plastic is used for making parts such as buttons, zippers, buckles, clips, hooks, rings, and fasteners.

- Sports and leisure: POM plastic is used for making parts such as ski bindings, snowboards, skates, helmets, goggles, gloves, rackets, balls, and toys.

What is POM acetal plastic?

POM acetal plastic is another name for POM plastic, especially the copolymer type. It is derived from the chemical name of POM, which is polyoxymethylene diacetate. It is also sometimes called polyacetal or acetal resin.

What is POM material application?

POM material application is the same as POM plastic application, as they are synonyms. It refers to the various uses and purposes of POM plastic in different fields and domains.

POM plastic is a remarkable polymer that has many advantages and benefits for engineering and consumer products. It has high mechanical strength, stiffness, wear resistance, low friction, dimensional stability, creep resistance, electrical insulation, dielectric strength, chemical resistance, thermal resistance, and easy processing. It is also safe for human health and the environment. It can be molded into sheets, rods, or other shapes and forms to suit various applications and needs. It can be found in many industries and sectors such as automotive, electrical and electronics, medical and dental, food and beverage, textile and clothing, sports and leisure, and more. If you are looking for a reliable and versatile material for your next project or product, you should consider using POM plastic. You can find high-quality POM plastic products at our online store. Visit us today and get a free quote!